How did your initial exploration of industrial metal waste lead to the development of Ignorance is Bliss as a research-based design project?

During my studies at Design Academy Eindhoven, in 2015, I was selected to participate in a three-month exchange program in Arita, Japan, renowned for being one of the first sites to produce porcelain in the country. My focus during this program was on local materials such as Izumiyama rock, Shirakawa stone, and others, which were traditionally used in porcelain and glaze production.

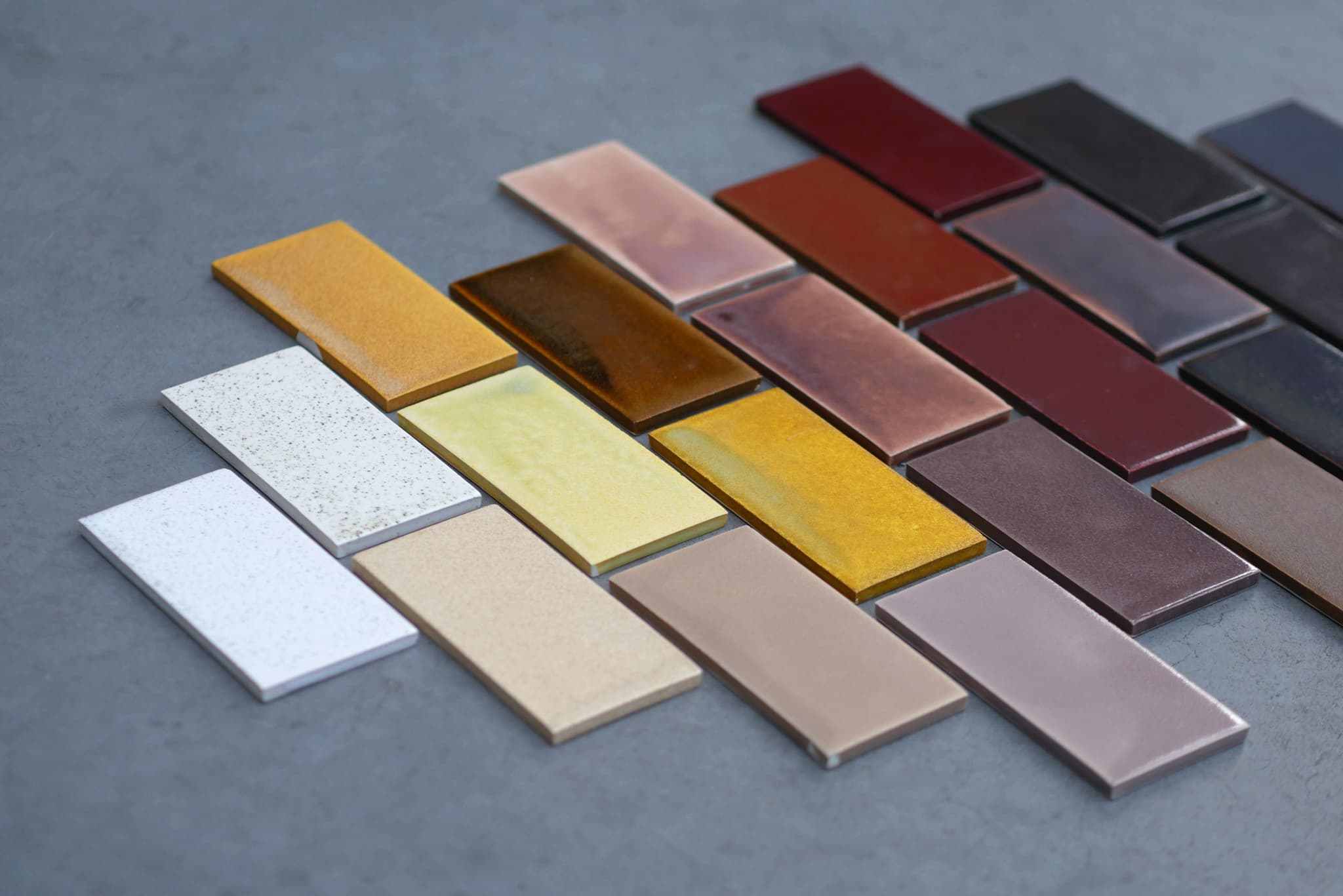

Upon returning to the Netherlands, I continued this methodology in my Ignorance is Bliss project. Understanding ceramics as a discipline rooted in chemistry, I learned that metal oxides play a crucial role in providing colour to ceramic glazes. Rather than opting for store-bought materials, I wanted alternative sources for these metals.

However, this pursuit wasn't without its challenges. Unlike readily available information, finding alternative sources for metals wasn't something I could simply search for online. It required extensive effort, including reaching out to various individuals and organisations through numerous emails.

Eventually, I received positive responses from a soil remediation company, drinking water supply companies, and a project focused on cleaning the pollution caused by a Zinc factory. These entities provided me with waste materials containing significant concentrations of metals.

While ceramics served as the initial focus point, I expanded my exploration to incorporate metal waste into other mediums such as glass and textiles. This multidisciplinary approach enriched the project, allowing for a more comprehensive exploration of industrial waste's potential in creative applications.

The project was growing, taking several directions; therefore, I decided that Ignorance is Bliss to become an umbrella term for various projects that involve industrial waste in design processes.

Can you explain the process by which Ignorance is Bliss converts industrial waste into higher-value products?

One might argue that when waste is utilised, the very notion of it loses its negative connotation. I aim to redefine waste by granting it a new identity - one that embodies potential rather than constraints. Despite its prevailing stigma in society, waste can be envisioned and harnessed as a raw material filled with opportunities.

Since the Industrial Revolution, ignorance and negligence have triggered widespread environmental pollution, with production facilities worldwide dealing with mounting volumes of residues and the accompanying disposal challenges.

Through extensive research into various waste streams, it has become evident that many can be repurposed in creative ways, seamlessly integrating into circular models of production.

Ignorance is Bliss solutions that substitute conventional factory-produced substances with waste or create entirely novel formulations and materials. With a primary focus on industrial waste and by-products, which often have consistent quality, my projects ensure a dependable supply chain.

Typically, secondary raw materials may not meet industry standards or may be contaminated, leading to their disposal or downcycling. By repurposing waste, I not only alleviate the strain on natural resources but also mitigate environmental pollution while maximising the utilisation of materials.

Presently, my main suppliers of waste and by-products come from various sectors including drinking water supply, soil remediation, agriculture, biofuel production, amber manufacturing, and natural stone manufacturing, predominantly located in the Netherlands and Lithuania.

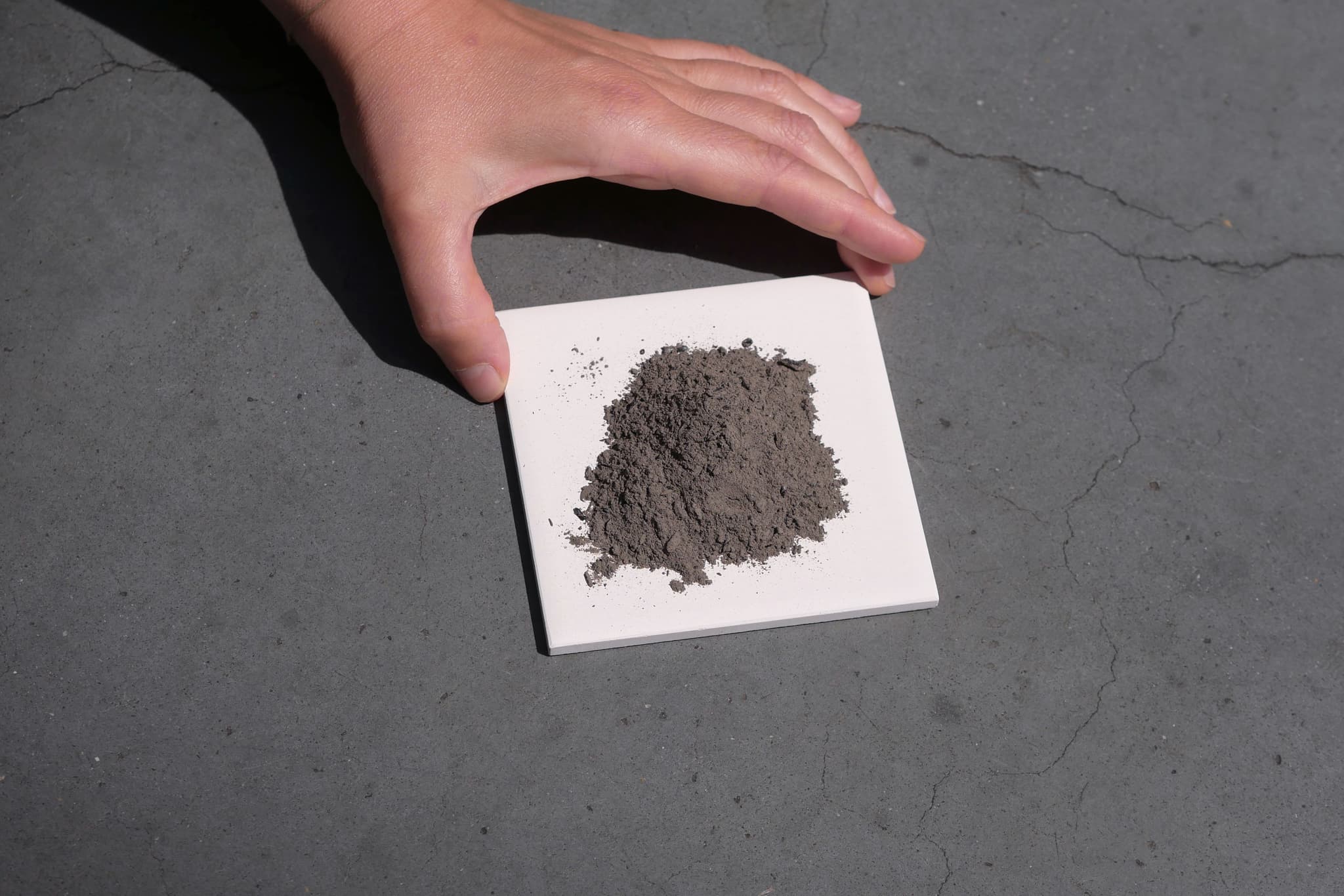

To illustrate, let's delve into the Ignorance is Bliss ceramic tableware and tiles project: Metal waste arrives in the form of sludge, often wet. This mixture has high concentrations of metals and organic matter. While no extraction process is necessary, the sludge undergoes meticulous preparation, including drying, milling, and sieving, to make it suitable for use as a pigment.

Once transformed into powder, it can be integrated into ceramics. During the firing process, minerals alongside metals play a crucial role, influencing the final outcome.

What are some of the challenges faced by production facilities in disposing of their waste, and how does Ignorance is Bliss offer alternative solutions?

Production facilities worldwide deal with significant challenges in disposing of their waste, contributing to environmental concerns on a massive scale. For instance, the soil remediation company in Weert, the Netherlands, alone generates approximately 30,200 tons of polluted material annually.

Similarly, the Antaviliai water treatment plant in Vilnius, Lithuania, responsible for supplying drinking water to half of the town residents, generates 5 tons of iron sludge each month. These figures underline the immense volume of waste generated by such facilities annually.

For instance, the Vilnius Heat Plant in Lithuania generates approximately 460 tonnes of wood ash waste monthly, primarily sourced from forestry residue for biomass energy production. Despite the non-toxic nature of the ashes, only a small fraction is currently repurposed for road fillers, while the majority ends up in landfills globally. This highlights the pressing need for alternative disposal solutions to mitigate environmental impacts and optimise resource utilisation.

Traditional methods of waste disposal, such as downcycling or landfilling, are not only environmentally detrimental but also economically burdensome for companies. While many designers engage with waste in their projects, merely creating dialogue falls short of addressing the systemic issues at hand. Collaboration between disciplines and industries are imperative to drive meaningful change and develop innovative solutions to waste management challenges.

Ignorance is Bliss aims to provide creative solutions and set an example within the industry. For instance, the Biofuel Waste is Bliss project collaborates with environmental scientists like Marija Spokaite to ensure environmental performance and credibility. By conducting thorough reviews of scientific literature and experiments, the project develops materials and architectural products that utilise waste in an environmentally optimal manner, addressing common concerns such as greenwashing. Taking a holistic approach, the project evaluates the sustainability of ceramic materials used in glazes, opting for ethical alternatives avoiding toxic substances like lead and barium. Moreover, it promotes ceramic innovation and renewable energy sources, motivating producers to adopt sustainable practices in their operations.

By utilising the natural iron content present in the ash as the sole source of colour for Biofuel Waste is Bliss products, the project effectively minimises environmental impact, conserves resources, diverts materials from landfills, saves energy, and reduces CO2 footprint. Importantly, incorporating such waste materials necessitates minimal changes to equipment or manufacturing processes, ensuring feasibility and scalability in adoption.

How does Ignorance is Bliss ensure the reliability and quality of the waste materials it uses in its design projects?

Ignorance is Bliss ensures the reliability and quality of the waste materials it utilises in its design projects through a rigorous selection process and adherence to safety standards. My projects primarily focus on industrial waste and by-products, which typically exhibit consistency, guaranteeing a dependable supply of high-quality materials.

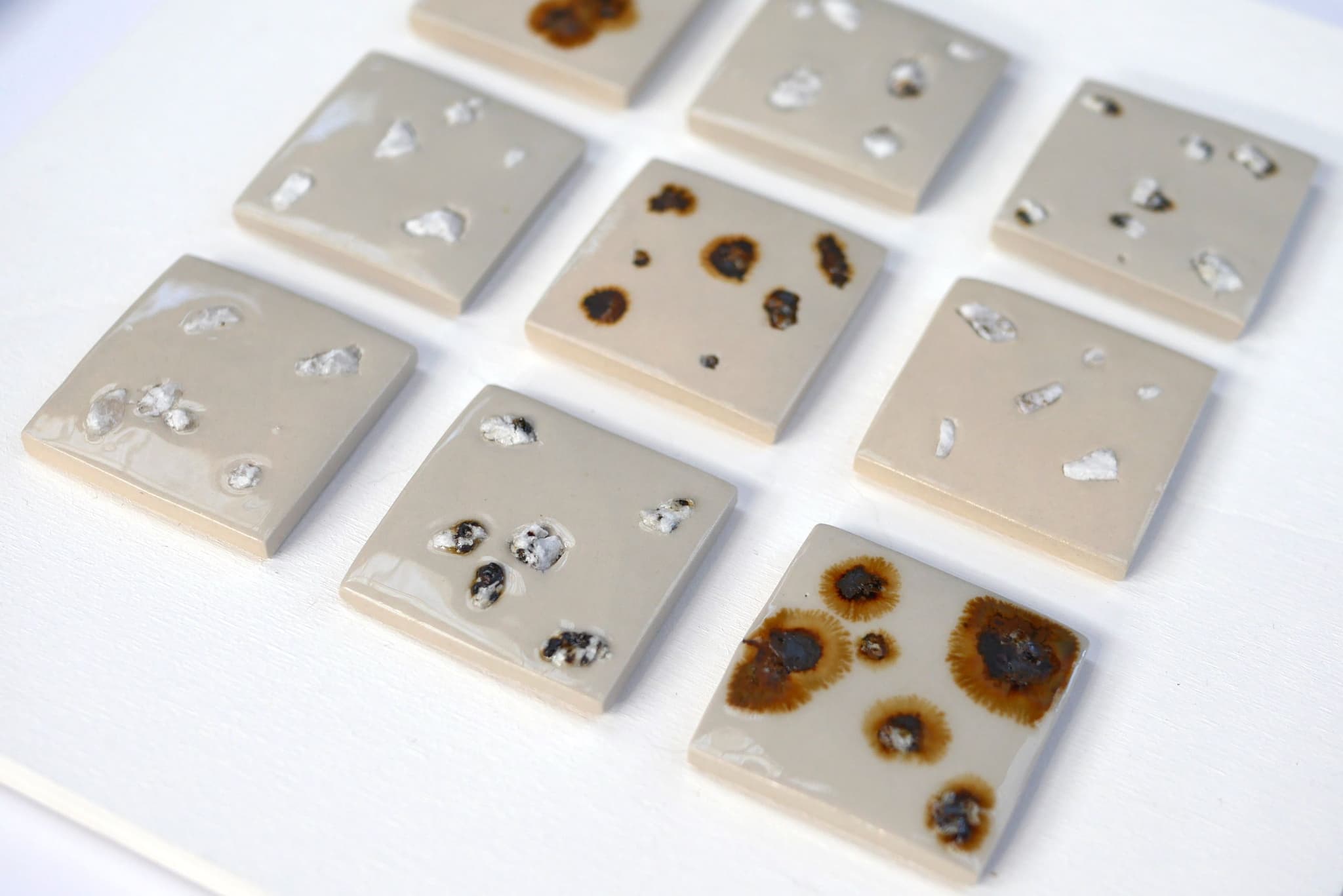

For instance, in the Ignorance is Bliss ceramic tiles project, concerns about the toxicity of certain waste materials frequently arise. Sludge obtained from soil remediation companies and zinc factories is deemed toxic due to elevated metal concentrations, posing potential risks to living organisms if inhaled or ingested.

However, it's important to note that not all waste materials are inherently toxic. Sludge from water industries, for instance, primarily contains iron, a non-toxic metal even in large quantities, thus posing no toxicity concerns.

Understanding the concerns surrounding toxicity in ceramics, particularly during the glazing process, is crucial. Many individuals are unaware that traditional ceramics often incorporate toxic materials, necessitating caution during handling. However, during the firing process at high temperatures, the chemical structure of the glaze transforms, making it inert and resistant to chemical leakage if properly balanced.

While some waste samples may contain trace amounts of toxic metals like lead and cadmium, these levels are well below harmful thresholds and pose no health risks post-firing. The composition of chemicals used in Ignorance is Bliss projects mirrors industry standards for ceramics, with the key distinction being the utilisation of waste materials rather than industrially produced colour pigments derived from the same metals. The approach ensures that any potential toxicity is effectively "locked" within the material, mitigating environmental and health concerns.

What is the significance of upscaling in Ignorance is Bliss, and how does the project balance this with craftsmanship?

The significance of upscaling in Ignorance is Bliss lies in its commitment to addressing the health and environmental impacts of products and materials throughout their life cycles. Recognising that we spend a significant portion of our time indoors, the project adopts a holistic framework that involves comprehensive studies of materials and their ecological footprints. This complexity necessitates collaborative efforts, transparency, and ongoing dialogue across disciplines.

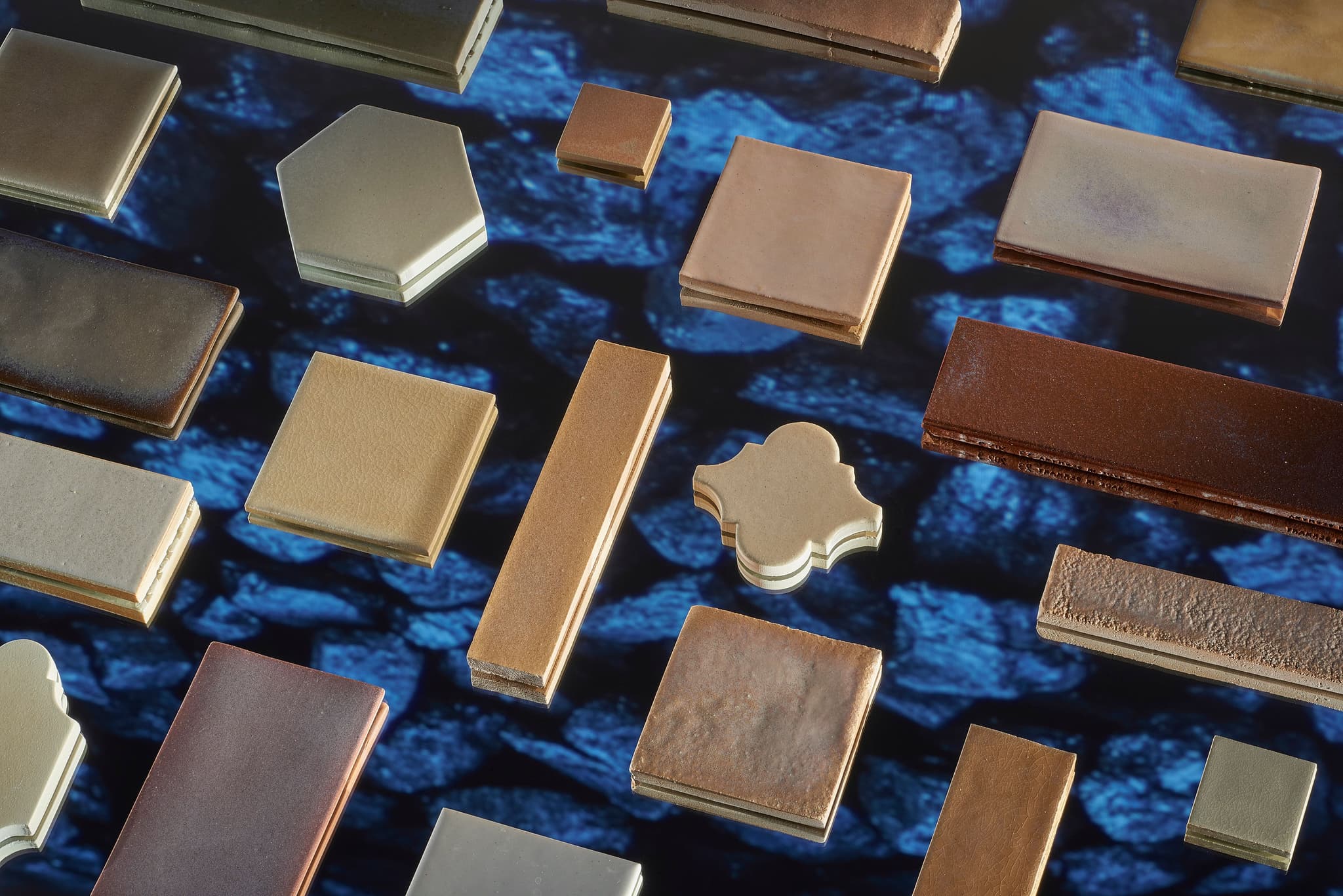

Upscaling plays a pivotal role in the project's objectives, although balanced with craftsmanship. Products crafted under the Ignorance is Bliss umbrella are not only functional and aesthetically pleasing but also designed with longevity in mind.

For instance, Ignorance is Bliss tiles can be manufactured in nearly unlimited quantities while adhering to principles of responsible design and production. The tile factories I chose to work with value handwork and craftsmanship. Everything is optimised in the factory, therefore even by producing tiles entirely or partially by hand, the process is fast. Each tile is not only glazed using 100% pigments from waste but is aesthetically unique. I've dedicated many years to developing distinctive and vivid colours, ensuring that each tile tells its own story and adds a touch of individuality to every space.

A notable step towards circularity was achieved in 2023 by replacing calcium carbonate, a common melting agent in ceramic production, with a calcium byproduct obtained from the softening process in drinking water supply industries. This substitution not only reduces environmental impact but also enhances the tiles' properties, such as hardness and durability. Up to 20% of the current glaze composition consists of calcium waste, further amplifying the utilisation of waste materials in ceramic tile production.

By embracing upscaling alongside craftsmanship, the project aims to set a precedent for responsible design practices that prioritise human and environmental health while offering viable solutions for sustainable living spaces.

Looking to the future, what are the next goals of Ignorance is Bliss?

The next goal of Ignorance is Bliss align closely with the European Union's ambition to achieve climate neutrality by 2050. Recognising the imperative for collective action at political and societal levels to reshape business strategies, I believe that design plays a pivotal role in driving sustainable innovation. Even individual designers and studios like myself have a significant part to play in stimulating fresh approaches to sustainability.

To truly make a meaningful impact on the environment and advance the circular economy, it's essential to integrate ideas on a large scale. I find myself most comfortable engaging in long-term projects, prioritising depth and dedication over speed. This approach is especially relevant when working on topics as complex as sustainability, requiring patience and steady commitment.

I envision continuing and evolving the Ignorance is Bliss project, exploring new directions and perhaps adopting new names as it progresses. There are countless possibilities for new applications and enhancements to existing ones. My latest project, which will be launched during Milan Design Week 2024, is titled Stone Waste is Bliss. This project focuses on repurposing waste generated by the natural stone industry, collaborating with Lithuanian company Akmenstata to transform stone offcuts and small pieces into eco-friendly homeware and surface collections.

Through playful research and experimentation, I aim to explore innovative methods of connecting stone with ceramics and other materials without relying on traditional adhesives. This research not only considers the inherent properties of each stone, including chemical analysis and melting points but also aims to transform waste into an eco-friendly homeware and surface collection.

Moving forward, I remain committed to seeking out diverse and challenging waste materials, constantly striving to uncover unexpected solutions. While the seriousness of climate change and our generational responsibility weigh heavily, I believe it's equally important not to lose sight of the joy and creativity in the design process. Embracing a playful mindset allows us to approach sustainability with renewed energy and enthusiasm, fostering innovation and driving positive change for our planet.