Key Points

- Intestines “bio-weld” as they dry, forming rigid structures without additives, coatings, or binders.

- Museum specimens over 200 years old prove long-term stability, guiding performance tests beyond lab benchmarks.

- The material’s only preparation is rinsing; all strength comes from native proteins, tension, layering, and drying cycles.

- End-of-life is naturally circular: pieces hold indoors but biodegrade outdoors without specialised disposal.

- Scaling depends less on fabrication and more on sourcing infrastructure - connecting designers, researchers, and industry around specific waste streams.

Full interview with Thibault Philip

Your work uses pig intestines, a visceral and highly symbolic material. What drew you to this particular offcut, and how did you technically prepare it for structural use in a design context?

Before industrialisation, intestines were a common resource: for musical strings in parts of Asia, wineskins in Africa, rainwear in North America, and bags in Europe. I’m interested in reconnecting with that older craft language while working with what is now considered industrial waste.

During my master’s, I became frustrated with imitating the living world using resins, silicones, and metals. I wanted to work more directly with living matter itself. After spending time with bioplastics, algae, and mycelium, I started researching animal-derived materials and realised how present they are in everyday products: haemoglobin in cigarette filters, proteins in cellular concrete, collagen in electronics. The scale of this use creates huge amounts of offcuts.

I eventually found GBB Boyaux Bretons, a company that sorts and sizes natural intestines for the food industry. They discard pieces that are too short, too long, or perforated. For the past five years, I’ve been working almost exclusively with these leftovers.

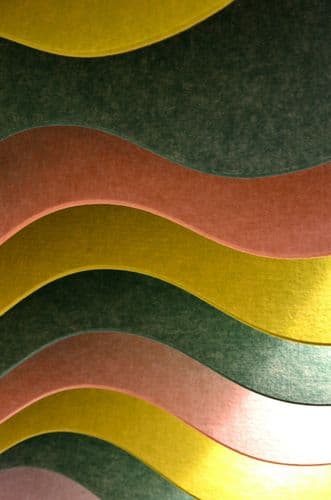

Together with researchers at the National Centre for Scientific Research, I’ve studied the material at a microscopic level. The proteins in the intestines allow them to “bio-weld” as they dry, so they can form sheets or structures without added glue or resin. My role is to understand these properties and translate them into simple, repeatable gestures in the studio.

Working with organic waste presents inherent instability. What specific preservation or hardening techniques did you explore to stabilise the pig intestine while retaining its natural translucency?

Very few, and that is exactly why I chose this material.

My aim is to intervene as little as possible and let the intestine show what it can do on its own. In collaboration with scientists, we observed under the microscope that the material is rich in proteins that naturally bond as it dries. This self-welding gives the pieces rigidity and stability without coatings or chemical hardeners.

The only preparation I do when I receive the offcuts from the company is to rinse them to remove the salt used for food preservation. After that, I work with drying times, layering, and tension, rather than with added treatments.

Pig intestines are rarely considered a viable material in contemporary design. How did you evaluate its performance characteristics, such as tensile strength, elasticity, or degradation?

My starting point was not a laboratory but museums. In collections, there are objects made of intestine that are more than 200 years old and still in good condition. That was my first indication that the material can last.

Once I connected with GBB Boyaux Bretons, I began a long phase of tests: stretching, layering, drying, re-wetting, exposing pieces to different conditions, and simply seeing what failed and what held. This experimental way of working is still central to my practice.

More recently, collaboration with the National Centre for Scientific Research has added a scientific layer. Using their tools, we can better understand tensile behaviour, elasticity, and how the internal structure changes as it dries. Intestines are already a highly “engineered” biological material, so their native shape and composition open up many technical possibilities that I’m still exploring.

What do you believe is missing in the current sourcing infrastructure that could help scale or streamline your practice?

A lot of the time in material research is spent not in the studio, but in building the right relationships: finding scientific partners, applying for funding, and setting up reliable supply chains. Better frameworks to connect designers, researchers, and industry around specific waste streams would make a real difference.

After several years, I have now built a network of partners across design, contemporary art, and science who help carry the work forward. But it took time, and much of it depended on personal encounters rather than structured programmes. More accessible research grants and interdisciplinary platforms for materials would make this kind of practice easier to start and sustain.

In the context of Letipoc, how did you address end-of-life considerations? Can these pieces be composted, or do they require specific disassembly or disposal pathways?

The pieces behave well in normal indoor conditions. In human environments where temperature and humidity are controlled, the intestine keeps its shape and, when dyed, its colour.

If someone wants to dispose of a piece, it doesn’t require a complex process. Land-animal intestines are not waterproof in the same way as those of marine animals, which is why Inuit rain capes could shed water while my objects cannot. When exposed to outdoor conditions, especially rain, the material gradually breaks down and is taken over by living organisms.

So the work is designed to be durable in use, but not permanent. It can return to the environment without specialised treatment.

Beyond the aesthetic or philosophical, what are the most critical material properties you now look for when working with animal-based offcuts, and how do you test or benchmark them?

I look for two things: technical richness and a clear end-of-life pathway.

Technical richness means a material that can take on multiple forms - thread, sheet, tube, plate - without adding other components. Intestines allow this kind of versatility, which lets me build objects from a single “ingredient” in different states.

At the same time, I want the work to last in use but not be immortal. I test this by making prototypes, living with them, exposing them to different conditions, and observing how they age. Scientific partners help me measure properties more precisely, but a lot still comes from direct handling: pulling, folding, drying, re-wetting, and sometimes deliberately breaking pieces to understand their limits.

This slow, iterative testing gives me a sense of which applications are realistic and which would be irresponsible.