The textile industry has been dealing with some serious environmental issues. From water pollution to massive waste generation, it's been quite a mess. Textile production is estimated to be responsible for about 20% of global clean water pollution from dyeing and finishing products.

If this stat isn’t alarming enough, consider the fact that the fashion industry is estimated to be responsible for 10% of global carbon emissions, which, quite surprisingly, is higher than international flights and maritime shipping combined. A single laundry load of polyester clothes can discharge 700,000 microplastic fibers that could potentially end up in the food chain.

In all of this, bamboo fiber presents a sustainable and environmentally-friendly solution for the textile industry. Its rapid growth, minimal need for chemicals, and biodegradability make it an ideal choice to address environmental concerns in the sector.

Understanding bamboo fibers and their environmental benefits

Bamboo plants are known for their rapid growth, making them one of the fastest-growing plants globally. Certain types of bamboo have been found to grow at up to 91 cm (35 in) per day. They sequester large amounts of carbon dioxide, contributing positively to the environment. A study found that bamboo can sequester 2.03 metric tons of carbon per hectare per year.

Bamboo is highly renewable, as it can be harvested after a few years without causing harm, and its extensive root system helps prevent soil erosion. It requires less water and fewer chemicals for cultivation compared to conventional crops like cotton.

Moreover, bamboo's natural pest resistance means that it necessitates fewer pesticides during cultivation, leading to a decrease in chemical pollution in soil and water bodies, safeguarding surrounding ecosystems.

Bamboo fibers are biodegradable, in contrast to synthetic fibers like polyester. When appropriately disposed of, bamboo-based textiles break down naturally over time, lessening the burden of textile waste in landfills and marine environments.

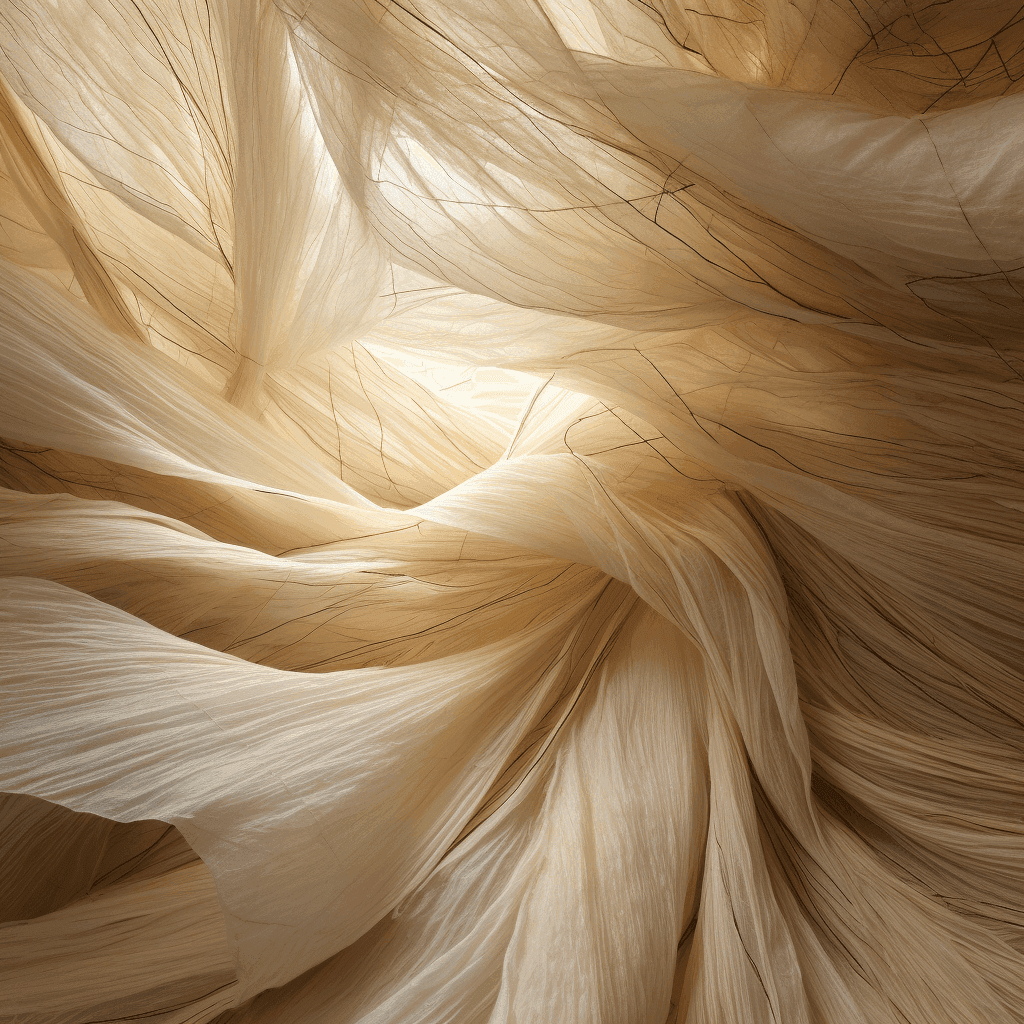

How bamboos go from stalk to fiber

Bamboo can be transformed into fiber using either a mechanical or chemical process. In the mechanical method, harvested bamboo stalks undergo retting, crushing, combing, and hackling to extract the fibers, which are then spun into yarn and woven or knitted into textiles.

The chemical process, more commonly used on a larger scale, involves dissolving bamboo cellulose in chemicals like sodium hydroxide, and extruding it into filaments, resulting in soft and silky fabrics.

Properties of bamboo fiber

Bamboo fiber has certain unique properties that help it stand out among the league of fibers. This is why it isn’t surprising that brands like Thought, Mary Young, Boody, and others have incorporated bamboo fiber into their products.

- Softness and Comfort: bamboo fiber is exceptionally soft and feels luxurious against the skin, often compared to silk or cashmere. In this aspect, it surpasses fabrics like cotton and polyester, which can be rough or less breathable.

- Breathability: bamboo's natural micro-gaps and moisture-wicking properties make it highly breathable. It allows air circulation, keeping the wearer cool and dry. In contrast, synthetic fabrics like polyester can trap heat, leading to discomfort.

- Absorbency: bamboo fiber is highly absorbent and can wick away moisture from the skin. This characteristic makes it an excellent choice for activewear and undergarments, outperforming fabrics like nylon, which tend to retain moisture.

- Hypoallergenic: bamboo is gentle on sensitive skin and hypoallergenic, making it a suitable option for those prone to allergies or skin irritation. In comparison, fabrics like wool may cause discomfort to some individuals.

Challenges and limitations affecting the adoption of bamboo fiber

The adoption of bamboo fiber in the textile industry faces various challenges and limitations that need to be addressed for its widespread use, such as:

- land use competition, as the cultivation of bamboo for fiber production may conflict with other important land uses, such as food production or preserving natural habitats

- achieving consistent fiber quality can be challenging due to variations in bamboo species and environmental factors, which is crucial for maintaining product integrity and meeting industry standards

- the chemical processing method used for most bamboo fibers can be environmentally and health-wise problematic if not properly managed

- the competition with well-established fibers in the textile industry and potentially higher production costs can impact the final retail price of bamboo-based products, affecting their affordability for some consumers

- Ensuring standardization and certification for sustainable bamboo fiber production remains a challenge, as the absence of consistent labeling schemes may create uncertainty for consumers seeking genuinely low-carbon products.

Despite these challenges, the bamboo apparel market is expected to expand at a CAGR of 6% from 2022 to 2032. Sales in the market are projected to cross US$ 4,026.9 million by the end of 2032.

Ongoing research and innovation are continuously working to address these limitations and make bamboo fiber production more sustainable, efficient, and cost-effective.

Final thoughts

Bamboo fibers offer a multitude of benefits to the textile industry, with their eco-friendliness setting them apart from conventional fibers. They present a sustainable solution to reduce environmental degradation, with their rapid growth, low water footprint, and biodegradability contributing to a greener future.

While bamboo fibers are gaining popularity, their current usage is still relatively limited compared to mainstream options. However, the potential for wider adoption is evident, as ongoing research and innovations address challenges, making bamboo fibers more efficient and cost-effective.

Brands in the textile industry have the opportunity to make a significant impact by considering bamboo fibers as a sustainable option for production.

References

Bamboo Apparel Market. (n.d.). https://www.futuremarketinsights.com/reports/bamboo-apparel-market

Bamboo Production | Project Drawdown. (2023, June 19). Project Drawdown. https://drawdown.org/solutions/bamboo-production#

Dwivedi, A. K., Kumar, A., Baredar, P., & Prakash, O. (2019). Bamboo as a complementary crop to address climate change and livelihoods – Insights from India. Forest Policy and Economics, 102, 66–74. https://doi.org/10.1016/j.forpol.2019.02.007

Emissions from planes and ships: facts and figures (infographic) | News | European Parliament. (2019, May 12). https://www.europarl.europa.eu/news/en/headlines/priorities/climate-change/20191129STO67756/emissions-from-planes-and-ships-facts-and-figures-infographic

Fastest growing plant. (n.d.). Guinness World Records. https://www.guinnessworldrecords.com/world-records/fastest-growing-plant

The impact of textile production and waste on the environment (infographics) | News | European Parliament. (2023, May 6).

Waite, M. (2010). Sustainable Textiles: the Role of Bamboo and a Comparison of Bamboo Textile properties (Part II). ResearchGate. https://www.researchgate.net/publication/231608434_Sustainable_Textiles_the_Role_of_Bamboo_and_a_Comparison_of_Bamboo_Textile_properties_Part_II