Key Points

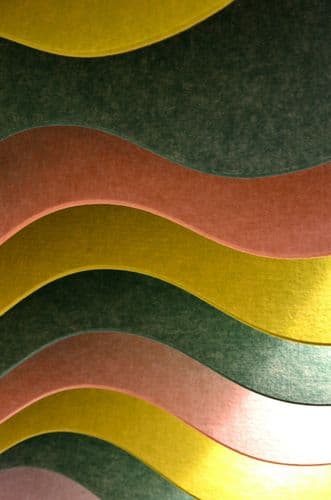

- Humane silk: Moths emerge first; pierced cocoons are used. Non-woven lace is bonded with a natural binder, with one matte side and one glossy side.

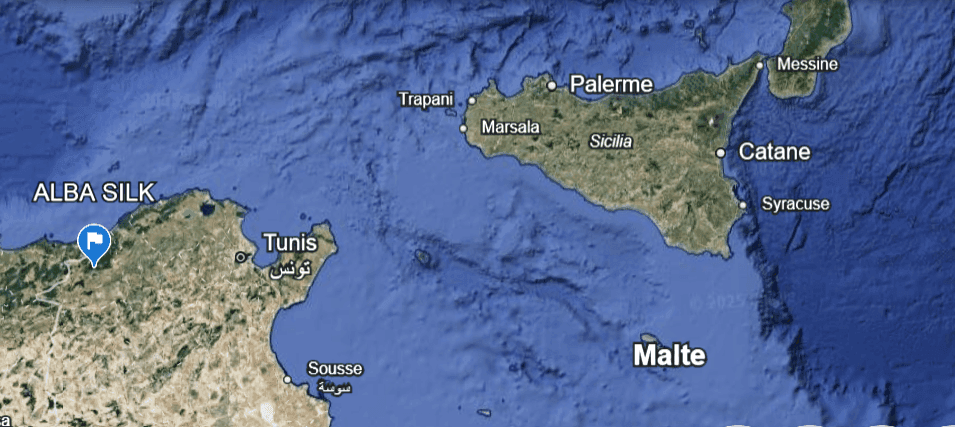

- Made in place: Beni Metir mulberry (no pesticides), zero-energy craft, and scaling via tree planting and training local women.

- Measured impact: ~150,000 trees on ~15 ha; ~1 L water per 10 m² of lace; farm-to-finish, logged on blockchain.

- Luxury-ready: Botanical dyes with strong colour fastness; packaging-grade tensile/abrasion; warm light diffusion for lighting and interiors.

- What’s next: 100% natural water-repellent finishes and natural resins for a glossy option; collaborations drive R&D.

Full interview with ALBA SILK

1. How did you develop a reeling method that preserves the chrysalis, and what does this mean for the material’s lifecycle?

Our proprietary transforming method emerged from a radical rejection of the industry norm: killing the chrysalis. We reversed the usual engineering priorities — instead of protecting the continuity of a single filament, we focused on processing shorter, open filaments left after the Bombyx mori moth naturally emerges.

Technically, this required us to develop tools that transform pierced cocoons without damaging fiber integrity. The result? A 100% Pet-Friendly lifecycle: the silkworm completes its metamorphosis, reproduces, and sustains the next generation naturally. Each meter of ALBA SILK Lace carries a verified narrative of life and continuity, making it a powerful storytelling asset in luxury.

2. What regional or agroecological challenges have you faced in Beni Metir, and how have they shaped the performance or scalability of your silk?

Beni Metir is a paradox: a remote, high-altitude forest ecosystem that’s poor in infrastructure but rich in purity. With no pesticides and minimal pollution, we were forced to adapt, and that constraint birthed our "Zero Energy" production model.

Our silk benefits from this: mulberry leaves here are exceptionally pure, resulting in filaments with superior tensile strength and luster. Rather than scaling through machines, we scale through human-centric replication: planting trees and training local women artisans.

3. Which stages of your process most contribute to a positive carbon footprint, and how are these impact reductions verified?

Three core stages define our Neutral Carbon Balance (on a path to carbon negative): 1/ Carbon Sequestration: 150,000 mulberry trees planted across 15 hectares. 2/ Zero-Energy Processing: just 1L of water per 10m² of lace, no thermal energy. 3/ Localized Supply Chain: full Farm-to-Finish integration eliminates global logistics emissions

Verification comes from internal lifecycle assessments, all transparently recorded on our blockchain traceability node, a data-backed system shared with partners.

4. What are the technical or logistical trade-offs of keeping your entire silk production localized?

Localization adds complexity. We’re not just artisans, we’re farmers managing living organisms. Unlike industrial commodities, our cocoons are non-standardized, requiring batch-by-batch quality control.

This means carrying inventory and climatic risks. But the upside is enormous: a short, secure, and ethical supply chain from Tunisia to Europe, free from contamination risks common in global sourcing.

5. How do your natural binders and dyes influence the structure, colour fastness, and tactility of the lace?

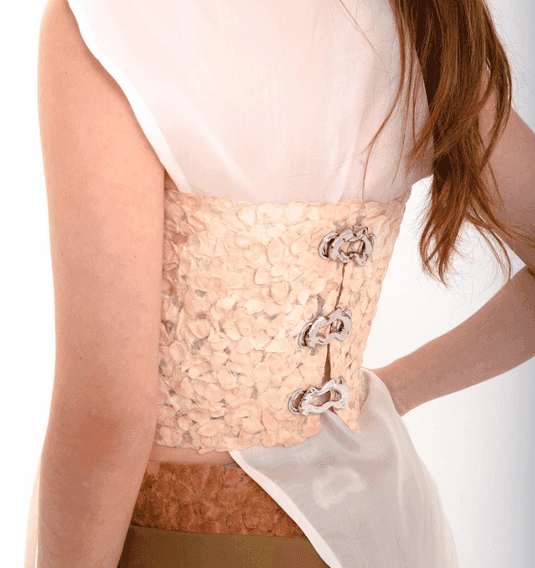

Our lace owes its uniqueness to a natural “glue” binder, developed over two years of R&D. It bonds at a molecular level with the silk’s natural gum (sericin), giving the lace a lightweight yet leather-like crispness. The duality of the material, one matte/rough side, one shiny/smooth, is a tactile hallmark.

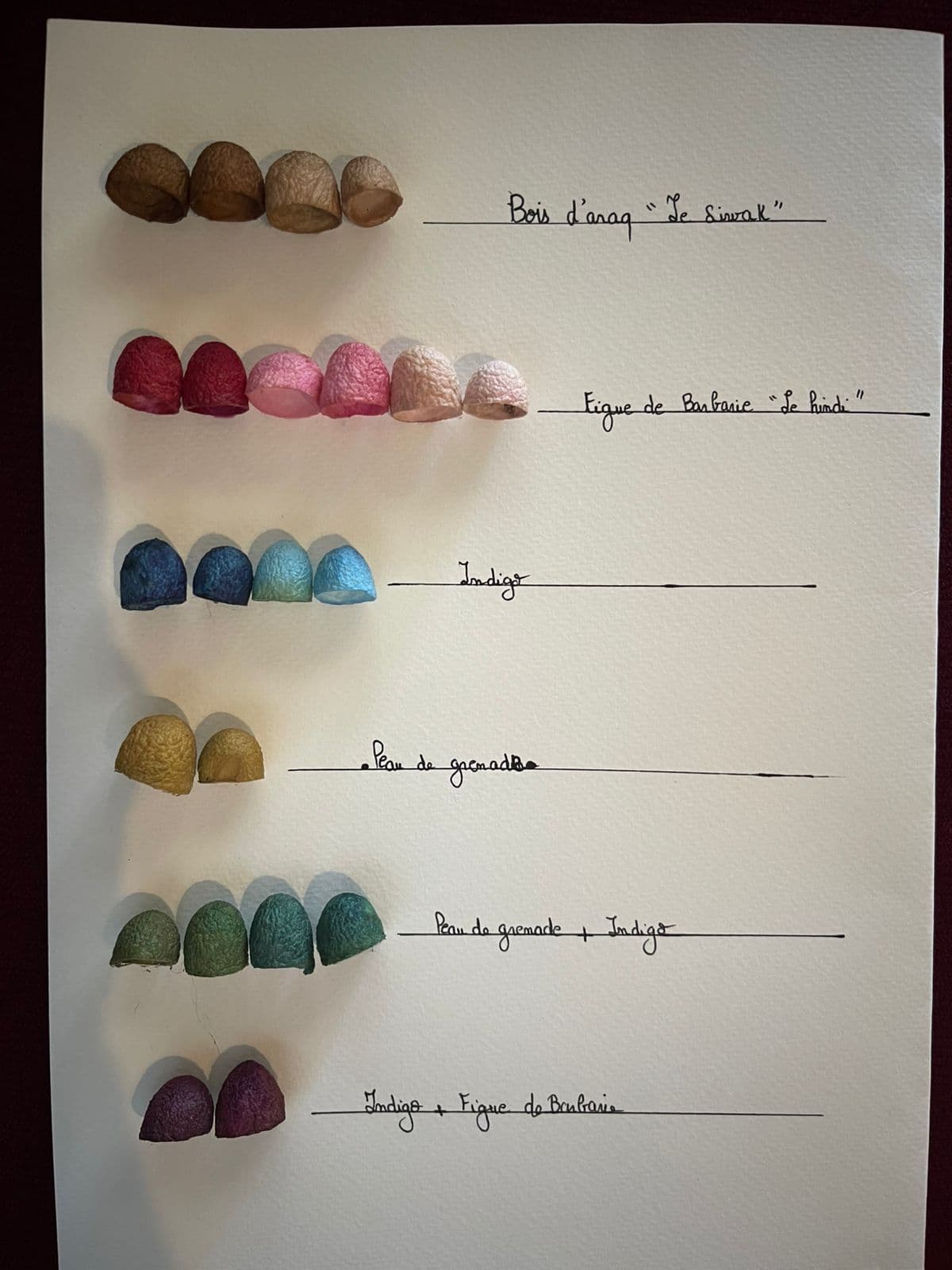

As for color: we use botanical dyes like henna, saffron, and prickly pear flowers. Combined with our proprietary mordanting process, we achieve deep, vibrant tones that meet luxury standards in colour fastness.

6. What innovations in loom setup or thread handling have helped you adapt traditional silk craft into lace making?

We moved away from looms altogether. Our non-woven, artisanal technique lays silk filaments in an organic, multi-directional web, bound with our bio-binder.

This meant inventing custom tools to tease and layer delicate, short filaments from pierced cocoons without further breakage. The result feels more like “painting with silk” than weaving it, bypassing energy-heavy spinning and weaving stages.

7. How do you assess the suitability of your lace for sectors like interiors or luxury packaging in terms of technical performance?

We offer personalized technical guidance from our in-house design and production team. We test prototypes with clients to ensure that every application lighting, packaging, interiors, meets luxury standards.

For lighting, the lace diffuses light with a warm glow. For packaging, it holds rigid shapes without plastic, passing tensile and abrasion tests to withstand high-touch environments.

8. How do collaborations with designers help push the aesthetic or structural limits of your silk lace?

Collaborations are our engine of innovation. Whether with jewelers or architects, each new project pushes the boundaries of scale, detail, or structural performance.

Designers like Amina Ben Ayed, Sadika Keskes, and Hassen Jeljeli have challenged us to rethink size, miniaturization, and even transparency. The act of creativity itself drives our R&D, we grow through co-creation.

9. What future developments in silk processing or finishing are you pursuing to broaden its technical or sourcing potential?

We’re developing advanced bio-finishes: water-repellent coatings that remain 100% natural, ideal for outdoor applications. We’re also testing natural resins to achieve the much-requested smooth, glossy finish without compromising ethical or material integrity.

The future of ALBA SILK is multi-surface, multi-sector, and still 100% pet-friendly.