Key Points

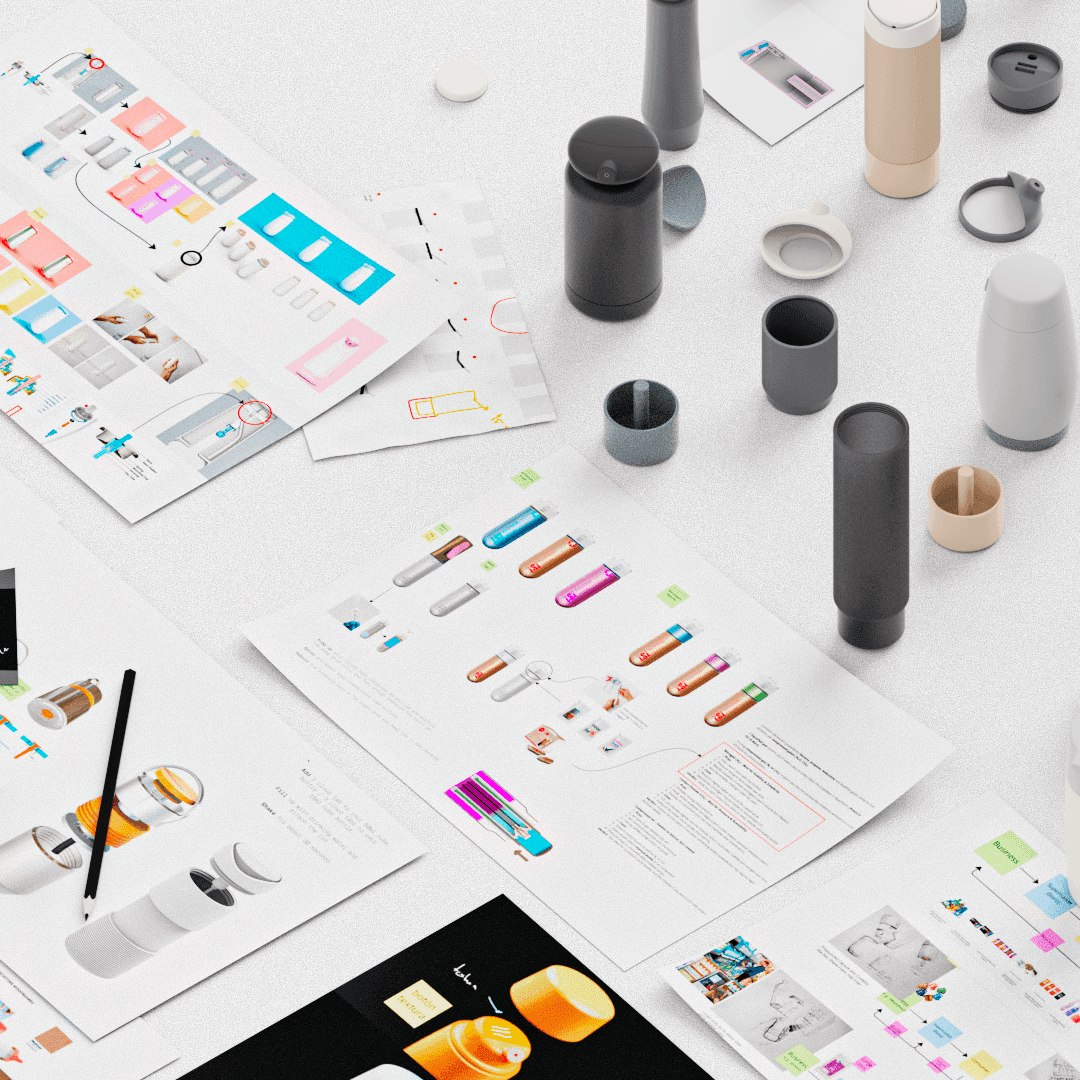

- NUBE replaces aerosols with a hand-pumped, gas-free container made from recyclable polypropylene (PP).

- PP was chosen for chemical resistance and broad compatibility across acidic mists to oil-based formulas.

- Cylindrical geometry and a one-way valve manage pressure cycles and reduce material stress over long-term use.

- A simplified pump with a single spring lowers part count, eases cleaning, and keeps components recyclable.

- End-of-life was designed for standard PP streams; future variants may trial bio-based pressure-capable polymers.

Full interview with NOS Design

1. What specific properties of the BPA-free materials used in NUBE made them ideal for repeated pressurisation and long-term reuse?

We use Polypropylene (PP) as our primary material. What truly matters is the concept—this is a product designed to be a lifetime partner for the user. It can be refilled indefinitely, significantly reducing the plastic consumption associated with single-use containers.

2. How did the material selection process ensure compatibility with a broad spectrum of formulations: from acidic facial mists to oil-based conditioners?

Polypropylene is one of the most chemically resistant materials among recyclable plastics available today. It's also an affordable choice, which made the entire project technically and economically feasible.

3. In shifting away from traditional aerosols, what technical hurdles did you encounter in achieving a continuous spray via hand-pumped pressure, and how did material design resolve them?

The first challenge was developing a new, patentable mechanism. Then came usability, we had to create a system that was simple to mass-produce, assemble, and clean. We conducted research on the typical quantities of liquids and gels used in beauty and wellness routines. With this data, we designed a container that could be easily hand-pumped to maintain constant pressure for daily use.

4. In terms of sustainability, what criteria did you use to evaluate the end-of-life recyclability of the chosen plastics or polymers?

We chose Polypropylene because it’s among the most recyclable plastics on the market. It allowed us to keep the design simple and ensured that, at the end of its life cycle, the product could be transformed into a new container.

5. How does NUBE address the potential for material fatigue, especially given its role as a lifetime-use container under fluctuating internal pressure?

The container's cylindrical shape distributes pressure evenly across its surface. Internally, it uses a one-way valve system controlled by a spring, minimizing internal stress. Unlike traditional pre-pressurized products, which often lose pressure and become unusable, NUBE allows the user to pressurize as needed, preventing waste and maximizing product usage.

6. Can you detail the design decisions behind the pump mechanism materials to ensure precision without reliance on metal springs or non-recyclable components?

We use a single spring to allow the system to close automatically. This choice eliminates the need for extra parts, such as an additional lid, and streamlines the design. A key advantage is that the pump and lid mechanisms are identical across both container sizes, making manufacturing and usage more efficient.

7. How do you ensure the materials resist leaching, staining, or degradation over time when exposed to a wide array of cosmetic formulations?

We rely on a proven material: Polypropylene. The innovation lies in the reusable mechanism and the simplified system. Users can purchase concentrated refills, which reduces both material waste and the carbon footprint associated with shipping diluted liquids globally.

8. Have you explored any bio-based or biodegradable alternatives to the current BPA-free plastics that could perform similarly in future iterations?

Yes, we’re open to integrating any material that can endure pressure and chemical exposure. This leaves room for innovation as new biodegradable and bio-based materials emerge.