Key Points

- Fermentation + green chemistry: bio-based pigments cut emissions by ~70% and are engineered to bind at fibre level without toxic fixatives.

- Drop-in, production-ready: works on standard mill equipment; formats (liquid/powder) validated on silk, cotton, denim with ISO fastness testing.

- Compliance track: ZDHC MRSL-approved reds/yellows and biodegradability passed; OEKO-TEX ECO PASSPORT, GOTS, LCA in progress.

- Waste-to-colour feedstocks: microbes run on agricultural/industrial by-products; pilots at 500–1000 L bioreactors for scale.

- Water & cost cuts: fewer rinse cycles and ~2× lower wastewater treatment costs in early tests; no fixing chemicals for selected products.

Full interview with Newera Bio

1. Newera Bio’s dyes are made by microbes through fermentation. How does this process work, and what makes it more sustainable than traditional dye production?

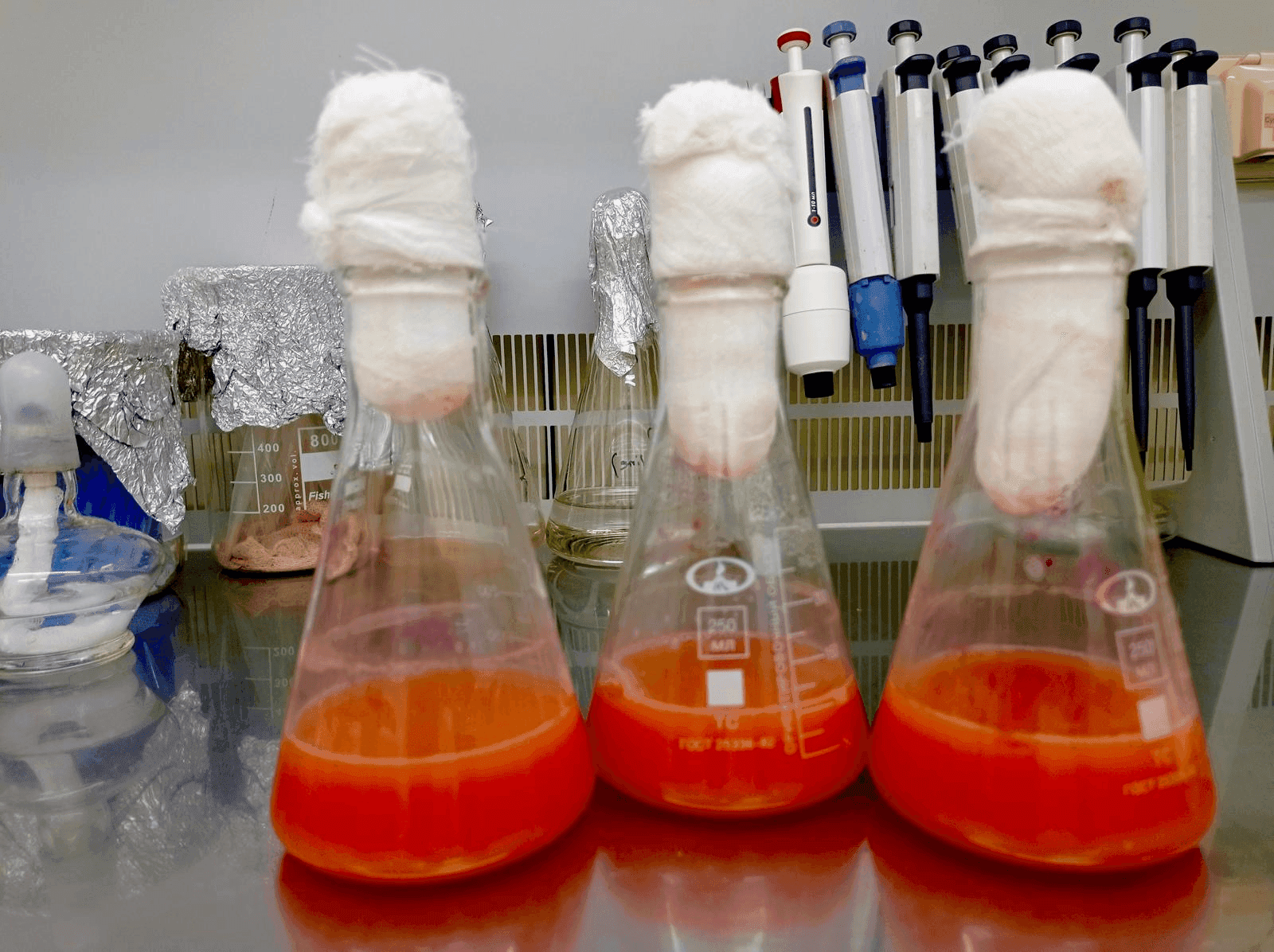

Our colour work starts in the lab - not with chemical cauldrons, but with microbes grown through fermentation. Some pigments originate this way; the rest of the transformation happens in our green-chemistry atelier, where we refine these microbe-crafted pigments into high-performance dyes with couture-level precision. Through a patented enhancement process, we give them the strength and finesse to bind to fibres with ease. The approach replaces fossil inputs with bio-based alternatives, partners with the University of Technology Sydney and the Australian Genome Foundry to convert waste into value, cuts emissions by around 70%, and is designed from the outset to be non-toxic and biodegradable.

2. What qualities do your bio-based dyes have that help them stick naturally to fabrics without extra chemicals?

The secret? A bit of chemistry sorcery. Our dyes don’t just cling, they commit. Thanks to our platform chemistry, natural pigment molecules are reworked to bind fibres at the molecular level. Add in our signature bio-based formulations, which act like a "molecular matchmaker", and voilà: colour that won’t ghost your garments after one wash. All this, with zero toxic fixatives.

3. How did you manage to get strong, long-lasting colours while keeping the dyes biodegradable and safe for the environment?

We refused to compromise. Our fermentation-born pigments are inherently biodegradable. But our genius lies in enhancing them with biochemistry that makes them pop, vibrant, durable, wash-proof, without sacrificing what matters: planet-first design. Our red and yellow shades already boast ZDHC MRSL certification and have passed biodegradability tests. Nature never looked so runway-ready.

4. What were some of the biggest technical hurdles you faced when switching from fossil fuel dyes to ones made with biology?

Natural dyes have long been the wallflowers of the colour world, beautiful but unreliable. Our challenge? Transforming them into headline acts. Performance, scale, consistency, all needed reinvention. Our answer was a custom enhancement and formulation platform, that lets biodegradable molecules stand tall beside their synthetic peers. This wasn’t evolution. It was a full-on makeover.

5. Can you walk us through what goes into producing one of your dyes, from growing the microbes to turning it into something ready for the textile mill?

Behind every vibrant hue lies a ballet of biology and biochemistry. It all begins with cultivating microbes: some wild, some expertly engineered, into colour-spinning factories through fermentation. We then scale this magic in 500L–1000L bioreactors, where science meets precision. Once the dye molecules are ready, our formulation team crafts bespoke dye blends tailored to the mill’s needs, whether liquid or powder, for silk or denim. Each batch undergoes rigorous quality checks to ensure stability and style, and we even develop eco-conscious dyeing protocols, tested on industrial equipment to guarantee performance in real-world conditions.

6. How do your dyes perform on different types of fabrics: like silk, cotton, or denim. And how do you test for things like fading or washing?

We’re textile polyglots. Silk, wool, cotton, polyester, even hair. Our dyes speak fluently. We perform in-house and ISO-standard third-party testing for lightfastness, washfastness, and rub resistance. And yes, we dye using industrial machines, because our pigments aren’t just pretty, they’re production-ready. Certifications? OEKO-TEX ECO PASSPORT, GOTS, LCA, all in motion.

7. Newera Bio uses agricultural waste to feed the microbes. How did you make that work, and what impact does it have on sustainability?

It’s the fashion equivalent of turning yesterday’s leftovers into next season’s bestseller. We’re engineering microbes that feast on agricultural and industrial byproducts, waste in, wonder out. This move closes the loop, nears zero carbon feedstock impact, and transforms forgotten streams into functional colour.

8. What steps does Newera Bio take to make sure your dyes are safe for people, for waterways, and for workers?

Safety isn’t a checklist, it’s our design brief. From the first molecule, we engineer for biodegradability and non-toxicity. Our dyes are tested and verified in world-class labs, complete with Safety Data Sheets (SDS). And yes, we’re getting all the right stamps, OEKO-TEX, GOTS, so that from factory floor to wardrobe, we protect people and planet.

9. Have any traditional dyeing methods influenced your approach, even though your process is driven by synthetic biology?

We’re inspired by tradition but don’t live in it. Our drop-in solution is built to slip into today’s textile mills without fanfare. No new equipment. No complex retraining. It’s sustainability with zero friction and all the flair.

10. How much water and energy can your dyeing process save compared to conventional dyeing, and how do you measure that?

Early tests show a dramatic reduction in water stress and waste headaches: no toxic additives, fewer rinse cycles, no fixing chemicals for select products, and 2x savings in wastewater treatment costs.

Soon, our Life Cycle Assessment (LCA) will reveal the full picture: water, energy, and emissions, quantified couture.

11. Newera Bio is working with mills and brands in different parts of the world. How do you keep your process adaptable for different regions and production needs?

We design for the global atelier. Our Australian pilot lab gives us nimbleness, rapid customisation, regional responsiveness. Add to that our industrial advisory panel and upcoming local manufacturing hubs in Asia, and we’re ready to serve fashion houses from Milan to Mumbai, with a lower carbon tab.

Watch how Dyeing Machine of Newera Bio works: https://youtu.be/lVYv9nIOcRo