In a design world increasingly shaped by regenerative thinking, a new generation of creators is not only inspired by nature — they build with it, alongside it, and sometimes even inside it. From bioluminescent algae to biodegradable sculptures, these 10 innovators are developing living, responsive materials that shift the boundaries of what’s possible.

Welcome to our shortlist of visionaries who are proving that the future of materials is not synthetic — it’s symbiotic. Whether working with fungi, algae, bone, or bacteria, these minds are reshaping design through biology, art, and systems thinking. Their work doesn’t just biodegrade — it breathes, evolves, and often glows.

These profiles aren’t just about form or function. They are about intelligence. Each project reflects a deeper story: a provocation, a protest, or a proposal for how we might co-exist with the materials we use.

Here are 10 MatterMinds building tomorrow’s living material landscape, selected by the Tocco team.

1. Chris Bellamy— Bioluminescent Algae, Lucid Life

A former engineer turned biodesigner, Chris Bellamy merges science and emotion through algae-powered light. His “Lucid Life” project explores bioluminescent microalgae as a poetic, glowing material for storytelling and connection.

What Tocco loves: The idea that a material can respond to human presence without wires or batteries is deeply compelling — a form of ambient intelligence built from nature. It’s both functional and spiritual.

2. Shijia Huang — Bone, Moss, and Microbes

Huang’s work reconstructs future landscapes using overlooked materials like bone and moss. Her installations reimagine decay not as an end, but as a living process — one that informs her architectural and ecological imagination.

What Tocco loves: We’re drawn to the deep material literacy in her work — the way she reads and reinterprets nature’s byproducts into design systems.

3. Nancy Diniz, Biomatters — Circular Bio-Labs

Biomatters is a design lab that grows mycelium, bacterial cellulose, and bioplastics — not just as alternatives, but as infrastructures for a circular future.

What Tocco loves: Their commitment to building locally grown, compostable material ecosystems makes them a key actor in applied biodesign.

4. Victória Kopp, Muush — Mycelium Biotextile

Muush blends fungi and fashion, creating mycelium-based textiles that are soft, suede-like, and fully compostable. Their work points toward a future where leather is grown, not skinned.

What Tocco loves: Their aesthetic precision makes fungal materials feel quite elevated, not a compromise.

5. Davide Viggiano — Bio-Sculptures & Synthetic Skins

Viggiano blurs the line between sculpture and skin, using degradable gels and hybrid materials to provoke questions around identity, decay, and the body.

What Tocco loves: His practice feels like biodesign meets philosophy — challenging and emotional in equal measure.

6. Polybion — Celium, Scalable Mycelium Leather

Celium is Polybion’s answer to the leather dilemma: a bacterial cellulose grown from fruit waste. It’s designed to meet the performance expectations of fashion and automotive industries.

What Tocco loves: they’re not just innovating — they’re scaling. Celium shows what happens when microbial materials meet industrial ambition.

7. Mycorium — Mass-Market Mycelium

Mycorium focuses on turning lab-grown mycelium into commercially viable leather alternatives. Their approach is pragmatic, performance-driven, and focused on global scalability.

What Tocco loves: Their engineering-first approach ensures fungal innovation won’t remain niche — it will become mass-market and accessible.

8. Angelo Renna — Soil Systems and Landscape Design

Renna designs with time, earth, and ecology. His work uses soil, seeds, and natural cycles to reshape how we think about permanence in architecture.

What Tocco loves: We admire his ability to design with decay — a true shift from resisting nature to collaborating with it.

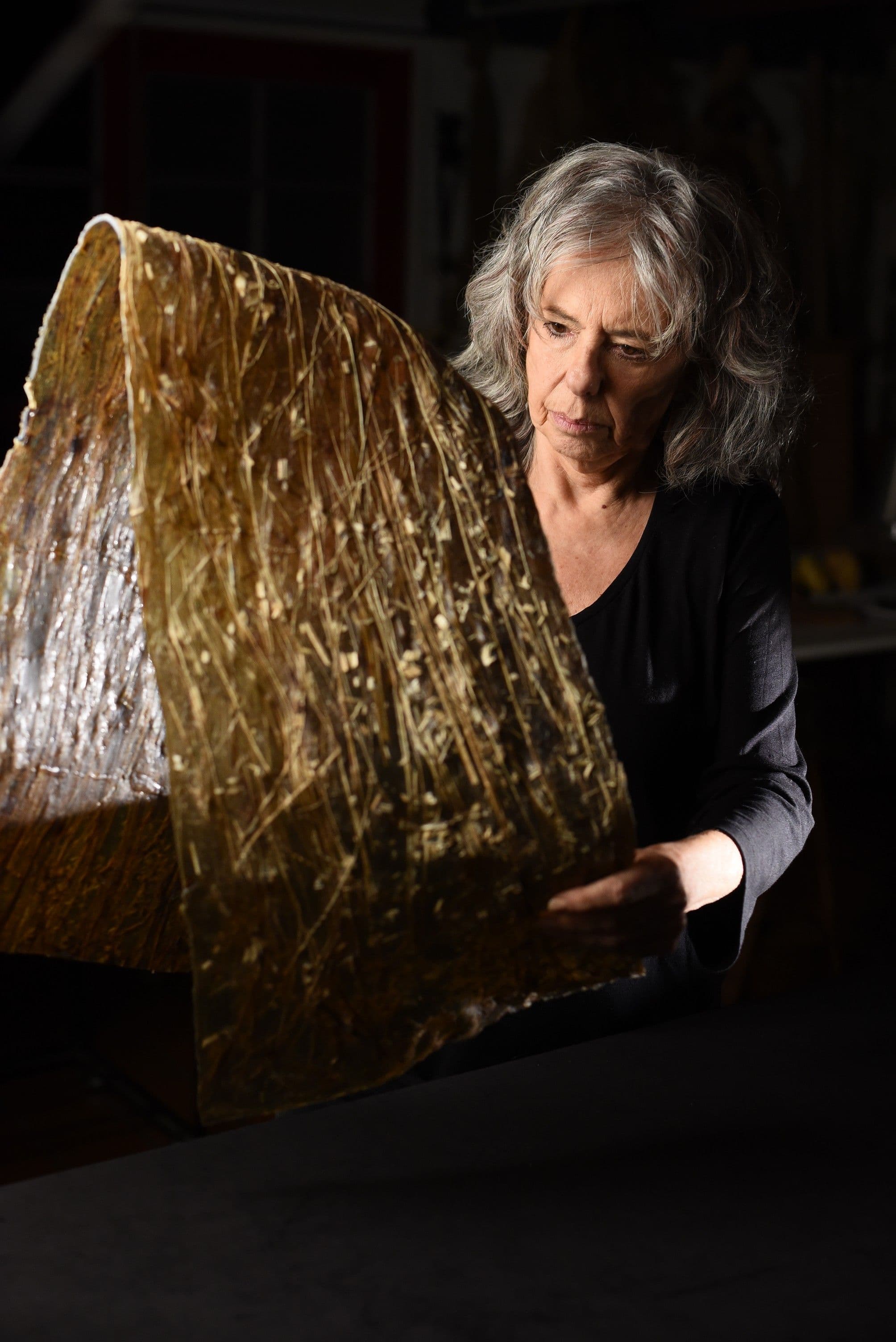

9. Laura Messing — Bioart & Moebio® Bioleather

Messing’s work transforms hair, waste, and biopolymers into sculpture. Her patented Moebio® material pushes the boundaries of what bioleather can be.

What Tocco loves: Messing treats material decay as narrative — a beautiful contradiction that makes her work both ephemeral and iconic.

10. Sabrina Merayo Nuñez — Alchemy of Matter

Sabrina’s biodegradable installations and material experiments dive into questions of transformation, permanence, and perception — always grounded in science, always poetic.

What Tocco loves: Her work embraces contradiction: growth and erosion, fragility and strength. She reminds us that materials are never just materials — they’re philosophies.