Key Points

- Designers and mills in North America and Europe are piloting Lite-1’s pigments; Asia is the scale prize as ESG rules tighten across textile supply chains.

- Performance matches or exceeds synthetics: rich hues, strong UV and wash resistance, and drop-in use without harsh fixatives.

- Impact is quantified via LCAs and water/energy metrics; replacing 1% of synthetics diverts industrial organic waste and avoids significant methane emissions.

- Scaling plan: leverage existing bioreactors (from breweries to fermentation hubs), cut culture time and raise yields, and drive COGS down 50–70% at 100,000 L.

- Platform is industry-agnostic: pilots span cotton–poly blends (TAL Apparel), bio-leathers (Desserto), and seaweed-based biopolymers (Flex-Sea).

Full interview with Lite-1

How have Lite-1's microbial pigments been received by product designers and industrial clients? Are there particular industries, sectors or countries that have shown the most interest or readiness to adopt these innovations?

Lite-1’s microbial pigments have been met with enthusiasm from both product designers and industrial clients, not just as a sustainable alternative, but as a performance-driven innovation that integrates seamlessly into existing manufacturing processes. Designers appreciate the depth and vibrancy of our colours, free from the ethical baggage of petrochemical dyes, while industrial partners see a drop-in solution that doesn’t require expensive overhauls. This shift isn’t just about sustainability; it’s about future-proofing supply chains. In the last five years, 85% of consumers globally have already changed their purchasing behaviours toward sustainability, and brands are scrambling to catch up.

The textile industry has been the fastest-moving adopter, particularly in Europe and North America, where ESG regulations are tightening and EU dye restrictions are making traditional options obsolete. Major apparel manufacturers in Asia, where the textile dye market is valued at $54 billion in 2024, have also expressed interest, not just for regulatory compliance but for long-term cost reduction. Beyond fashion, biopolymers and alternative materials have emerged as early adopters, with pilots already underway for bio-leathers, seaweed-based packaging, and textile manufacturers seeking cleaner colour solutions.

Geographically, Asia is the biggest prize, home to the bulk of global textile production and the most aggressive regulatory shifts. However, North America has proven to be the earliest adopter, driven by corporate sustainability mandates and consumer demand for clean products. The question is no longer if the industry will transition, it’s who will lead and who will scramble to catch up. Lite-1 isn’t here to follow the market; we’re here to define it.

What comparisons can you draw between the durability and visual performance of microbial pigments and conventional synthetic dyes? How have these differences influenced client feedback?

Let’s start with the myth: synthetic dyes are the gold standard for durability and performance. The reality? They were the best option in a world that didn’t demand clean, circular materials. Lite-1’s microbial pigments match or exceed synthetic dyes in colour vibrancy, stability, and application versatility, all while eliminating the toxic baggage of petrochemical production. Our dyes bind effectively to both natural and synthetic fibres without requiring the harsh chemical mordants that degrade fabrics over time. The result? Longer-lasting colours, better material integrity, and a process that requires less water and energy.

When it comes to durability, microbial pigments have proven highly resistant to UV degradation and wash cycles, outperforming conventional organic dyes and rivalling synthetics. In lab and pilot trials, our pigments retained 90% of their original intensity after 50 industrial wash cycles, a benchmark that synthetic dyes struggle to meet without fixatives and toxic additives. Additionally, microbial dyes do not fade unevenly or bleed excessively, issues common with synthetic alternatives. Clients in the textile and biopolymer industries have noted that our dyes provide richer hues that age more naturally over time, aligning with premium and high-performance markets.

The real shift comes in how brands think about colour. Historically, dye performance was judged purely on stability at any cost, usually a mix of heavy metals, formaldehyde, and fossil-derived binders. Now, the conversation is about high-performance colour without planetary compromise. Brands piloting Lite-1’s pigments have doubled down on material innovation, viewing colour as an asset rather than an environmental liability. In short? Microbial colour isn’t just a replacement for synthetics, it’s an upgrade.

How does Lite-1 measure and communicate the environmental benefits of its pigments, such as lower greenhouse gas emissions and water usage, to clients seeking precise sustainability data?

Lite-1 speaks the language of numbers, not vague green promises. We quantify impact through Life Cycle Assessments (LCAs), water use reduction metrics, and comparative carbon footprint analysis. Our microbial pigments require zero petrochemicals, eliminating the 12% of global oil demand that feeds synthetic dye production. Water use? Traditional textile dyeing accounts for 20% of global wastewater, while our pigments require water only once, during the initial fermentation process, without ever releasing contaminated effluent into ecosystems.

In concrete terms, scaling Lite-1’s pigments to replace just 1% of the current synthetic dye market could divert 14,800 tons of industrial organic waste from landfills, preventing 28,701 tons of methane emissions, a greenhouse gas 80 times more potent than CO₂. Our bioreactor-based process cuts energy consumption compared to fossil-derived dyes, with an estimated 50% lower carbon footprint per kilogram of pigment produced. These aren’t estimates pulled from thin air, they’re based on real, lab-tested impact assessments conducted with leading sustainability researchers and industrial partners.

We provide clients with hard data in a format they can act on, whether for ESG reporting, regulatory compliance, or supply chain optimization. Our approach resonates because it removes the greenwashing guesswork. Brands don’t just need sustainability; they need measurable proof. And at Lite-1, we deliver exactly that.

“Petrochemical dyes are the past: dirty, destructive, and outdated. Our competitors? Many are still stuck in single-industry solutions, whether it’s algae, yeast, or textile-specific applications. Lite-1 is different. We’re industry-agnostic, drop-in ready, and built for scale, delivering high-performance colour without the petrochemical baggage. Less water, lower emissions, zero toxins. It’s not just a cleaner alternative, it’s a superior product.” Roya Aghighi, Co-founder of Lite-1"

What are the main hurdles Lite-1 faces in scaling microbial pigment production for industrial use, and what solutions or innovations are being implemented to overcome them?

Scaling any biotechnology solution from lab to industry isn’t a plug-and-play operation, it’s an engineering challenge. For Lite-1, the biggest hurdles aren’t just biological but also economic, infrastructural, and driven by industry inertia. The first major challenge? Production volume and cost parity with synthetic dyes. Industrial dye houses are accustomed to dirt-cheap, mass-produced petrochemicals, with synthetic dyes priced as low as $5–$10 per kg. Our initial commercial pricing will be competitive with high-end organic and synthetic dyes, targeting $30–$50 per kg at pilot scale. As we scale production to 100,000L bioreactors, our Cost of Goods Sold (COGS) will drop by 50–70%, bringing us into direct price competition with conventional options. To achieve this, Lite-1 is optimizing fermentation yields, reducing per-unit costs through precision bioprocessing, and integrating waste-stream feedstocks to replace expensive lab-grade nutrients.

The second challenge? Manufacturing scale. Bioreactor capacity is a bottleneck in microbial dye production, but rather than reinventing the wheel, Lite-1 is leveraging existing biomanufacturing infrastructure, from retrofitted breweries to industrial-scale fermentation hubs. This sidesteps the massive CAPEX of building dedicated facilities while allowing fast, flexible scale-up. We’ve also cut culturing time by 1066% and boosted pigment yield by 80% through process optimization, proving that microbial dyes aren’t just viable, they’re commercially competitive.

Finally, industry adoption. Change is hard when supply chains are deeply entrenched, but Lite-1’s drop-in formulation means brands and manufacturers don’t need to overhaul their processes, just swap their input. By working directly with major textile and materials companies, we’re embedding microbial pigments where they belong: as the new industry standard. Scale isn’t a question of if, it’s a question of how fast we get there.

How versatile is your biofabrication platform in accommodating different materials and industries? Can you share examples of successful adaptations or customizations?

Lite-1’s biofabrication platform isn’t just versatile, it’s modular, scalable, and industry-agnostic. Unlike competitors focused on a single material (textiles) or a single bio-source (yeast, algae, or fungi), our system is designed to work across multiple industries and substrates. Whether it’s natural fibres like cotton, synthetics like polyester, biopolymers, or alternative materials like mycelium and seaweed-based films, Lite-1’s pigments integrate seamlessly. This flexibility isn’t accidental, it’s the result of a proprietary bioengineering and formulation process that fine-tunes colour adherence, stability, and performance for different applications.

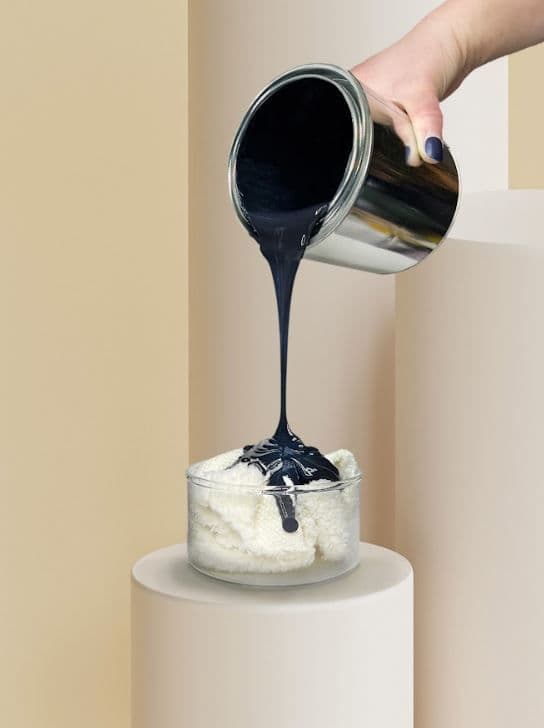

Our early pilots prove this adaptability in real-world settings. In textiles, we’ve successfully formulated a blue dye for cotton-polyester blends in collaboration with TAL Apparel, a major Hong Kong-based manufacturer. In bio-leathers, our custom black pigment is currently in trials with Desserto, a leader in plant-based leather alternatives. Meanwhile, in biopolymers, Lite-1 is working with Flex-Sea, a UK company developing seaweed-derived packaging films and 3D printing filaments, to create biodegradable, non-toxic colourants for next-gen packaging solutions.

This multi-industry approach isn’t just about flexibility, it’s about future-proofing colour. Legacy dyes were built for one thing: fossil-fuel textiles. Lite-1 is building for the future of materials, ensuring clean, high-performance colour isn’t a compromise, it’s the default standard.

What processes or technologies ensure consistent pigment quality as production scales from laboratory to industrial levels? Are there variations that need specific attention during this transition?

Taking microbial pigments from lab breakthroughs to full-scale industrial production isn’t just about making more, it’s about ensuring precision, consistency, and performance at every stage. At Lite-1, we’ve built quality control directly into our biofabrication process, using strain engineering, precision fermentation, and advanced downstream processing to maintain pigment integrity at scale. Our microbial strains are optimized for stable, high-yield pigment expression, meaning we don’t experience the batch-to-batch variability that often plagues organic or plant-derived dyes.

The biggest challenge at scale is maintaining colour fidelity and yield efficiency in larger bioreactors. Lab-scale production operates in flasks (1L to 5L), where environmental conditions are tightly controlled. As we expand to 1000L and eventually 10,000L bioreactors, we use automated bioprocess monitoring, adjusting factors like pH, oxygen levels, and nutrient flow in real-time to keep microbial performance optimal. This has already paid off, our work with The Verschuren Centre has helped us cut culturing time by 1066% and boost pigment yield by 80%, ensuring our process remains commercially viable without quality loss.

The final piece? Downstream processing and formulation. Extraction and purification must be cost-efficient, scalable, and maintain colour stability across applications. Our approach minimizes energy use and waste, using a combination of physical (high-pressure homogenization) and chemical (solvent-free extractions) methods. This ensures that whether Lite-1’s pigments are being used in textiles, biopolymers, or cosmetics, the colour remains as rich, stable, and high-performance as promised, no compromises.

How can interdisciplinary collaboration across science, design, and industry accelerate the broader adoption of biofabricated pigments? Are there critical gaps in technology or understanding that require collective action?

The colour industry wasn’t designed for disruption, it was built for scale, cost-cutting, and petrochemical dependency. Breaking that cycle takes more than scientific breakthroughs; it requires cross-disciplinary collaboration between scientists, designers, and industry leaders. Science provides new biological tools, design translates them into market-ready materials, and industry supplies the manufacturing muscle to deploy them at scale. When these forces align, adoption accelerates, just look at how plant-based leathers and biomaterials have evolved from niche experiments to full-scale production in under a decade.

The biggest gap isn’t just technology, it’s education and infrastructure. Brands are eager for clean colour solutions, but dye houses and manufacturers often lack the technical expertise to integrate biofabricated pigments seamlessly. Without industry-wide knowledge-sharing, innovation risks stalling at the R&D stage instead of reaching the market. Collective action is needed to train dye houses in microbial pigment processing, establish certification standards for bio-based colours, and invest in biomanufacturing infrastructure to replace outdated petrochemical dyeing systems.

At Lite-1, we don’t just develop technology, we bridge the gaps. We partner with designers to test and refine colour applications, manufacturers to validate performance at scale, and sustainability leaders to build regulatory frameworks that support biofabrication. The future of colour isn’t just about replacing synthetic dyes, it’s about redefining how industries think about materials in a world demanding cleaner, smarter, and circular solutions.