Key Points

- Culture matters: Material choices are tied to place and craft; sustainability must reflect cultural context as much as environmental impact.

- Circular-by-design: Starts with the material; prioritises local sourcing, low energy, minimal waste, and clear end-of-life—e.g., repulped bacterial cellulose to standardise quality and usability.

- Pragmatic change for brands: Consultancy breaks big goals into staged, durable steps to avoid greenwashing while meeting cost, aesthetics, durability, and permitting realities.

- Next-gen materials to watch: Living/algal colouration and photosynthetic coatings; PFAS-free, single-polymer performance textiles (e.g., superhydrophobic fabrics designed for recycling).

- Market fit tests: Tangible user excitement (“wow factor”), viable pricing, and unambiguous end-of-life pathways (recyclable where/ how; home vs industrial compost).

Full interview with Adele Orcajada

How have your experiences working with communities in Peru, Ecuador, Europe, and Asia informed your approach to material innovation and sustainability at MaterialDriven?

When I first started working in Perú and Ecuador, I was drawn to the visible connection the artisans and makers had with autochthonous materials which were almost invariably natural materials such as seeds, wool, or alpaca. The identities of the local communities were strongly tied to the way these materials were grown, harvested, and then transformed: it was a way of life as much as an economic source for them.

This connection struck a chord with me as I realised that sustainability had to be understood through its cultural ties as much as its environmental impact. Understanding materials as a central focus of the design process was a shift that completely changed the way I designed and created.

From my time in Europe and Asia, I developed a true understanding and respect for the manufacturing process, whether artisanal or industrial, gleaning powerful insight into the ways materials can be manipulated to become design artifacts.

I was also fortunate to be in the UK when the concept of material innovation became a real “thing” and designers began to explore and investigate the potential of working with living organisms to create a new generation of biomaterials. This opened a whole new realm for me and I became fascinated by the creative potential of biology. All these experiences combined came together to help me understand materials as tangible reflections of our culture, identity, and relationship to nature.

When I was working in Ecuador for a US accessories brand that worked mostly with seeds, I truly had interesting cross-cultural experiences, since I had to work as a go-between for the US team and clients and the indigenous local artisan makers. I remember once when a US client asked us if we could deliver our signature necklaces without “ugly seeds”, referring to those that sometimes were not round, or had strange marks.

After an initial struggle, we were able to make them see that the beauty in our collections was in the imperfections, that showed off the organic nature of the material we worked with. In the end, they were able to incorporate this narrative into the communication and marketing of the collection which was positively received by consumers.

With your background in making and developing craft accessories for fashion, how do you integrate principles of circularity and sustainability into the design process?

The starting point for me has always been the material, understanding how it behaves, and what sort of emotions it elicits from us. But alongside this more sensorial connection to materials, there is always a respect for the way we source the material, the way we work with it, and how the end of its life will be.

The aim is to work as nature, striving to make human intervention as seamless as possible. This ambitious goal makes us as designers even more creative and imaginative than ever, ensuring that circularity and ethical design are always at the forefront of our decisions.

Trying to work with local raw materials, reducing the amount of energy needed to produce/harvest/manufacture the material, avoiding waste and offcuts, providing ways to reuse them, and also embedding strong material narratives into the final artifacts are ways that I find are important to ensure a responsible and circular design process.

Working with Bacterial Cellulose has been very inspiring for me as a designer. Through its cultivation and harvesting, I have had many exciting but also many frustrating results. One of the constant issues, was the lack of control on the outcome of the leather-like material when it was harvested as a sheet material and left to dry naturally. The surface would vary depending on growth conditions, from smooth and translucent, to irregular, wrinkly, bumpy, holey….This made it very difficult to control the final aesthetics.

However, I did not want to discard any of the bacterial cellulose that was being produced, so were searching for a way to take advantage of this raw material. We began to experiment by blending the bacterial cellulose into a pulp and we discovered that if we spread the pulp out onto sheets, eventually it would dry and resemble the leather-like sheets we liked, but we could control the thickness, the finish and ensure that all the pieces were the same. And we were excited to discover that the sheets dried better and were easier to sew and manipulate.

MaterialDriven is known for exploring material innovation with brands and institutions. Could you discuss a project where your consultancy has significantly impacted a brand's approach to sustainable material use?

A few years ago, Material Driven was working with the architectural studio in London on a project to design a retail space that was looking to be the most sustainable store in the city. Although we were excited to see that this big brand was invested in taking big steps to endorse sustainable values, we soon realised that there was a side of reality that needed to be contemplated during the decision-making process for the design of this space. Cost was going to always be a priority, as were aesthetics and durability and certifications that would be required to get the correct permits.

During this consulting process, we not only assessed the selection of exciting sustainable materials, but we helped the company understand the key pillars that defined their sustainable values as a brand and helped them break them down into steps so that these could be implemented at a more realistic pace, while we also worked on a strong, transparent narrative that could connect their consumers to their sustainable transformation process.

This is very much aligned with how MaterialDriven believes in circularity. We strongly believe that it is better to take small but sturdy steps towards sustainable design, ensuring that these changes are durable and long-lasting and that these will lead to more changes, when possible, rather than trying to make many changes that won’t work in the long run and can end up sounding like greenwashing.

Given the rapid evolution of clean material trends in the fashion industry, what insights can you share about emerging materials that are set to transform the industry?

There has been a definite increase in interest in new generation materials, set to transform the design and fashion industry, with a rising number of innovators reaching the market and securing millions in investment, although one of the major issues is the complexities in scaling up and achieving the standards that consumers are used to.

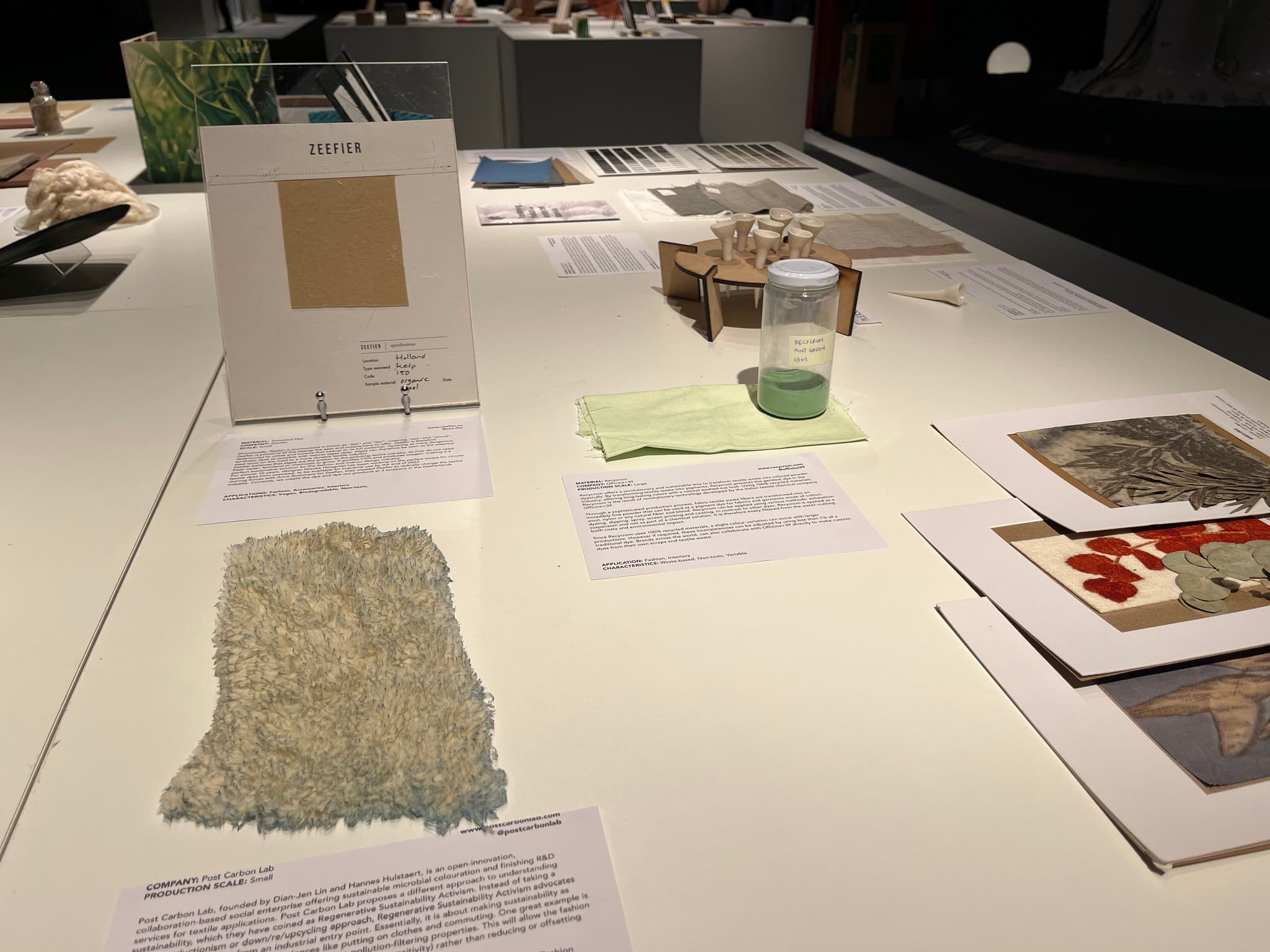

However, research and “out of the box” thinking are still going strong, with exciting ideas that are setting out to shape our future, such as photosynthetic dyes or coatings made with microalgae that are living as we wear them on our clothing, purifying the air around us and don’t need to be washed as often as conventional garments, further reducing water usage. This means that these biomaterials are not only respecting nature, but they are also playing an active role in regenerating it. Pneuma and Post Carbon Lab exemplify this trend.

Another exciting trend is the use high performance textiles that abide by Green Chemistry principles, rather than using toxic chemicals. Water-repellent fabrics have traditionally used PFAS and breathable textiles are usually made of layered materials that then are hard to recycle at the end of use.

AmphitexTM by Amphico is a great example of a material that uses a fabric called AmphidryTM that is inherently superhydrophobic and requires no extra chemical coating to make it water-repellent, it has been designed using the same material in all its layers so that any offcut can be recycled and reused in the production process.

One of MaterialdDriven’s aims is to connect material innovators with brands and institutions that are looking for new materials, so for us, it is vital to create awareness regarding all these exciting new products that are being developed. We do this through our main 3 services which are education, curation, and consulting. Through these services, we aim to put as many professionals (current and future) in front of these materials and explore their potential and possible applications.

How do you evaluate the commercial potential of new materials developed by the new generation of material makers? What criteria are most important for assessing their viability and sustainability?

We need to see how the general public and professionals physically engage with the material. You can almost always tell when they are excited to discover a material…the ‘wow’ factor that makes them want to touch and smell the samples, and ask more questions to learn more. This is a key factor, to see if this is a material that they can see a use for, or that they get excited about.

Of course, other criteria are important to contemplate and evaluate and it depends on the sector and the interested company but two issues that continually come up at our exhibitions and during our consultations are price and end of life/use.

Regarding price, designers and consumers are aware that sustainable materials will be more expensive, but at the moment they are sometimes more than 3 times more expensive and this is still an issue especially if they are small design studios.

On the other hand, when talking about end-of-life/use, they are looking for materials that have a clear narrative in this aspect. They want to know if they are recyclable, how is it recycled and where they (or their customers) take the material for it to be recycled, or if it is biodegradable is it compostable at home or only industrially? There are still many grey areas, hidden in greenwashing marketing that are confusing to users.

What message do you consistently emphasise to your audience about the role of product designers and material scientists in advancing the circular economy within the fashion industry?

The key message I always stress is that they, we, are responsible for what we design and put into the market. We need to realise that anything we make can potentially end up in landfill if we don’t choose the right materials, or think of its end of life and impact on the environment and humankind.

It is not an option to be a sustainable designer, but rather a responsibility.