Key Points

- Spirulina works indoors: high photosynthetic efficiency and resilience enable visible, effective air purification in office settings.

- Modular, repairable builds: fir wood frames with algae-based 3D-printed joints are dry-assembled for reuse, maintenance and low impact.

- Mycelium informs layout: parametric rules based on fungal growth guide paths, aeration and load-bearing zones in exhibitions.

- Closed-loop materials: harvested algae become biopolymers for 3D printing; systems track biomass, air pollutants and site-specific performance.

- AI-guided forms: voxel models optimise light, airflow and surface area for photobioreactors, scaling from room modules to façade systems.

Full interview with ecoLogicStudio

1. What properties of Spirulina microalgae did you find most critical in enabling the seasonal stability and air purifying efficiency of the AIR.garden installation in London?

Spirulina microalgae are remarkable organisms - among the oldest and most efficient photosynthetic life forms on Earth. For the AIR.garden installation, their resilience and adaptability were crucial to achieving both seasonal stability and air-purifying efficiency in a living system integrated within an office interior in central London.

From a biological standpoint, Spirulina’s metabolic flexibility allows it to thrive in a wide range of temperatures and light conditions, making it ideal for fluctuating indoor microclimates. It is also ten times more efficient than terrestrial plants at capturing carbon dioxide and releasing oxygen through photosynthesis. This high photosynthetic rate directly supports air purification, while its ability to assimilate nitrogen oxides and other airborne pollutants enhances overall air quality.

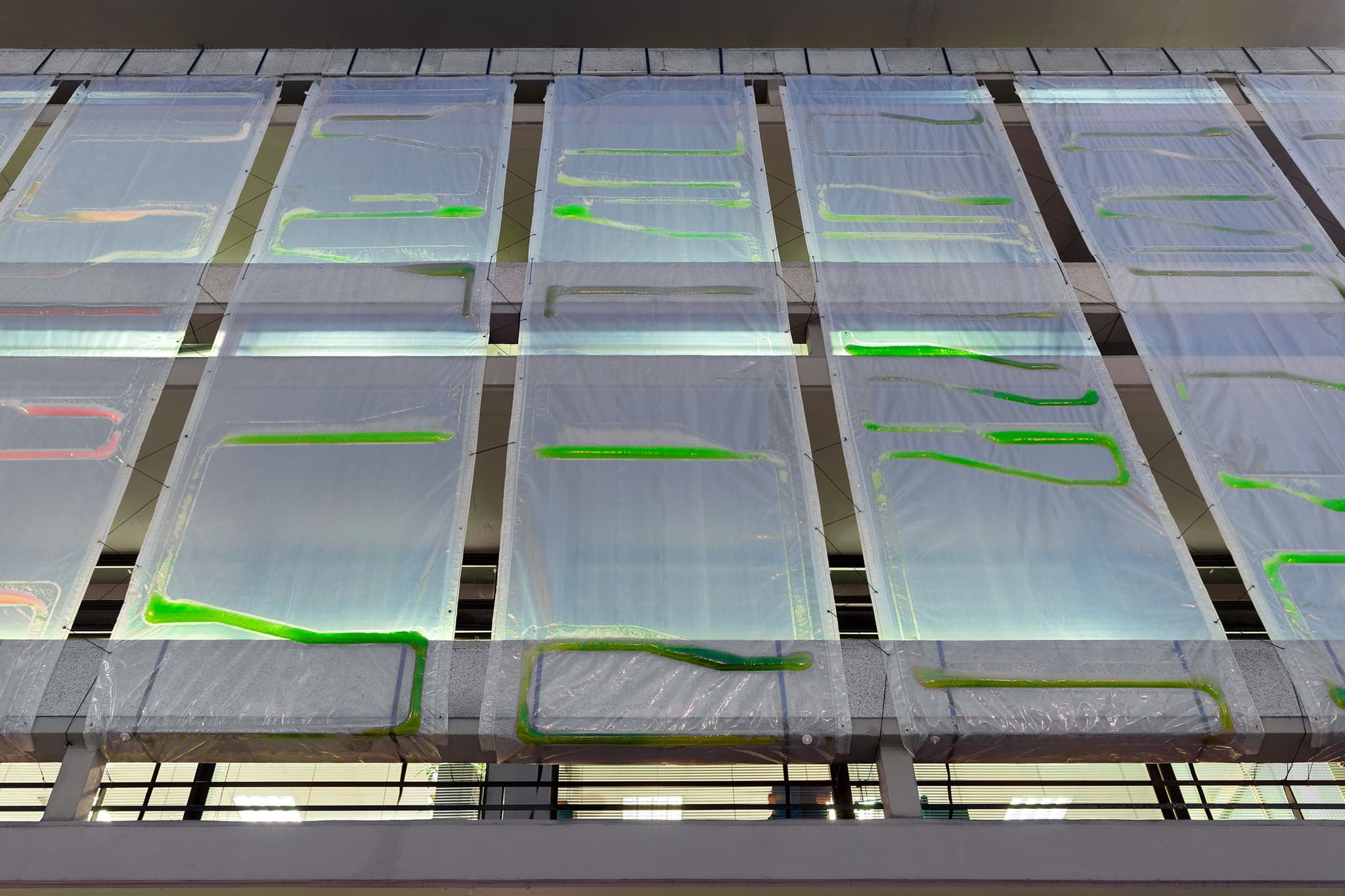

At a design level, Spirulina’s density and vibrant pigmentation make the biological process visible - transforming an invisible metabolic exchange into a living, aesthetic experience. The glowing green bioreactors not only purify the air but also serve as a visual reminder of our connection to the atmosphere and the cycles of life that sustain us, even in the heart of the city.

2. In Design Apothecary, you’ve modularised an algae photobioreactor system using fir wood, stainless steel fasteners, and 3D printed joints. How did you evaluate the mechanical and ecological performance of this hybrid assembly under long-term use?

In the Design Apothecary, we set out to demonstrate that biotechnological systems can achieve architectural integrity through natural and circular materials. The structure combines fir wood with 3D-printed joints made from algae-based biopolymers, creating a hybrid assembly that is both materially efficient and ecologically restorative.

The system’s mechanical performance was validated through iterative prototyping and digital simulations, testing strength, flexibility, and long-term stability. Designed for reversibility, every component can be assembled and disassembled repeatedly without adhesives or permanent fasteners, ensuring durability, ease of maintenance, and adaptability over time.

Ecologically, the project follows a life-cycle approach: fir wood acts as a biogenic carbon sink, while the algae-derived joints embody circularity by transforming the same microorganisms that purify air into structural components. The system’s scalability ensures it can grow and evolve while maintaining material coherence.

What makes the Design Apothecary unique is that our team lives and works within it - algae cultivation, harvesting, and daily use are integrated into our domestic and creative routines, making sustainability a lived, regenerative practice.

3. Deep Forest employs mycelium as both structural and spatial logic. Could you describe how you parametrically defined its growth pattern to inform pathways, aeration, and load-bearing elements?

The growth patterns of mycelium were not left to chance. Using a combination of time-lapse observations of fungal colonization and computational modeling, we parametrically defined its expansion, density, and directional flow.

These simulations informed the layout of the engraved pathways, aeration ducts, and the distribution of the 3D printed synthetic bark components.

By translating mycelial growth logic into parametric rules, the architecture could optimize air circulation for both human and microbial activity, and guide visitors’ movement along paths inspired by the natural hyphal network. In this way, the fungal organism became both a design medium and a generator of spatial structures, with its metabolic logic shaping the physical environment of the exhibition.

4. The biophilic systems in your projects serve multiple functions such as air purification, food production, and material generation. How do you balance these overlapping material roles while maintaining system resilience? Refer specifically to how biomass from algae is repurposed.

Carbon dioxide and nitrogen dioxide are responsible for global warming, pollution, and the contamination of the land. All of these chemical elements that are the cause of contamination for our respiratory system are actually nutrients for the microalgae. While feeding on these substances, they remove them from the air molecules to build new cells and multiply.

During harvest events, algae cells are filtered out of their liquid medium, where they normally grow, to extract the biomass from which the biopolymer is extruded. Biomass can be used for food, medical purposes, as well as the production of biopolymers.

This process was first unveiled three years ago to the public in the Otrivin Air Lab space, which was on show in London at the Building Centre. Visitors could directly interact with microalgae, harvest them, and transform them into biopolymers and biofilaments for 3d printing.

5. In Otrivin AIRlab, you convert harvested biomass into 3D printed bioplastics and neti pots. What technical challenges did you encounter in algorithmically controlling feedstock variability to ensure consistent print quality?

Working with organic materials means that every printed product is unique, which ties in with a concept we call digital craftsmanship.

Parametric digital modelling and 3D printing are combined with natural materials that are subject to unique growth conditions, requiring a degree of care and craftsmanship similar to that needed when working with clay or wood.

6. AirBubble and HORTUS installations leverage living organisms for pollutant removal. What tests or metrics do you employ to quantify these systems’ carbon offsetting performance, and how do you calibrate them for site-specific conditions?

To quantify the carbon offsetting performance of AirBubble and HORTUS installations, which leverage living organisms like microalgae and plants for pollutant and carbon dioxide removal, a combination of direct and proxy measurements is used. Here’s a detailed overview:

1/ Carbon Uptake Measurement via biomass accumulation. We track growth rates of plants or algae in the system over time. Biomass data is converted to carbon uptake using standard conversion factors (e.g., ~50% of dry biomass is carbon).

2/ Gas Exchange Measurements via microalgae-based air monitoring. We monitor stress-induced changes in algae (e.g., pigment shifts, photosynthetic inhibition) as proxies for CO₂ uptake efficiency under different pollutant loads.

3/ Air Quality and Pollutant Removal Metrics. Track reductions in co-pollutants such as NOx, particulate matter, and VOCs using ambient air sensors. Though not directly carbon, improved air quality often correlates with enhanced photosynthetic efficiency and indirect carbon capture.

7. PhotoSynthetica and TreeOne use AI-driven fabrication with algae-derived polymers. Could you specify the AI parameters or generative logic that informed form generation in order to maximise carbon capture efficiency?

Both PhotoSynthetica and Tree.ONE employ a generative AI design process that simulates and optimizes the complex interactions between form, structure, and biological performance. The algorithm doesn’t simply produce geometry; it encodes a coevolutionary logic where material behavior, photosynthetic activity, and fabrication constraints are interlinked.

In practical terms, the AI model operates on a voxel-based spatial grid that defines the potential volume of the structure. Each voxel is assigned multiple parameters, such as light exposure, surface curvature, airflow dynamics, and fluid circulation efficiency, all of which influence local photosynthetic productivity. Through iterative simulation and optimization, the algorithm “learns” to favor morphologies that maximize the surface-to-volume ratio, enhance light diffusion, and improve CO₂ absorption across the bioreactors.

This multi-objective optimization produces a form that is both structurally efficient and biologically performative. The final geometry is then translated into a fabrication script that guides robotic 3D printing using algae-derived biopolymers, ensuring that digital precision and material intelligence converge in a continuous bio-digital feedback loop.

In essence, the AI doesn’t design for nature - it designs with it. The resulting forms, as seen in Tree.ONE, are not static sculptures but living machines, their geometry tuned to optimize the metabolic dialogue between architecture and the atmosphere.

8. Across your work, from exhibitions like Deep Forest to retrofit spaces like Design Apothecary, how do you assess the lifecycle or end of life prospects of your bio-integrated assemblies, especially the biodegradable or compostable elements?

Across projects such as Deep Forest and Design Apothecary, we approach every bio-integrated assembly as a living system with a defined material lifecycle, from cultivation to decomposition. Our assessment begins at the design stage, where materials are selected not only for performance but also for their regenerative potential at the end of life.

We employ a life-cycle thinking methodology that combines digital simulation, empirical observation, and material prototyping. Biodegradable and compostable components, such as our algae-based biopolymers, are monitored over time to study how environmental conditions affect their degradation and how their biomass reintegrates into the ecosystem.

Rather than seeing end-of-life as disposal, we frame it as re-metabolization: materials are returned to natural or productive cycles. For instance, algae residues can become feedstock for new 3D-printed components, plant fertilizer, or even nutrition.

This regenerative loop defines the core philosophy of PhotoSynthetica, designing architectures and products that behave more like organisms, capable of evolving, adapting, and reintegrating into the biosphere, thus eliminating the notion of waste.

9. In your modular biodesign systems, how do you tackle the trade-off between reversibility for adaptive reuse and structural robustness, especially when integrating living elements like algae or mycelium?

In our work, we deliberately move beyond the notion of modularity, which implies repetition, standardization, and the logic of mass production. Instead, we adopt a systemic and circular approach, where components are designed as part of a living ecology capable of transformation, re-metabolization, and adaptive growth.

Reversibility, in this context, is not a constraint on structural robustness but a principle of material intelligence. Every joint, interface, and component is designed to maintain integrity through change, to be disassembled, repaired, or reconfigured without loss of performance. This allows our systems to evolve alongside their biological counterparts, such as algae or mycelium, whose growth cycles demand dynamic adaptation.

We test these assemblies through iterative digital simulation and real-world prototyping, ensuring structural performance while preserving the capacity for material regeneration. Robustness, for us, is achieved not through permanence but through resilience, that is the ability of a system to continuously adapt while retaining coherence and ecological balance.

10 Looking at scalability, how might you adapt the AIR.garden model to denser urban typologies or retrofit interventions in high-rise contexts while maintaining its biophilic and health-centred objectives?

We can distribute smaller modules across buildings rather than relying on a single large installation. In a high-rise, the reactors could be, for example, integrated into façades, balconies, or even HVAC systems, where they would benefit from existing airflows and technical spaces.

We have already tested this approach in projects like Photo.Synth.Etica curtain in Dublin and Helsinki, where photobioreactors were integrated into the skin of a building. In dense urban contexts, modularity also means resilience: if one module fails, others continue to operate.

11. Emerging materials like algae biopolymers and mycelium composites offer opportunities for adaptive facades. What is your vision for integrating these into large-scale architectural envelopes or urban systems in future projects?

Emerging materials like algae biopolymers and mycelium composites are opening exciting possibilities for living, adaptive architecture. At ecoLogicStudio, we are exploring how these materials can transform façades and urban systems into dynamic surfaces that respond to environmental conditions - filtering air, modulating light, or even capturing carbon.

Tree.ONE is a tangible demonstration of this approach: a 6-meter-tall living sculpture where AI-driven generative design, robotic fabrication, and algae cultures come together to create a structure that is both functional and alive.

Looking forward, we envision scaling these principles to entire buildings and neighborhoods, creating regenerative urban ecosystems where architecture, technology, and living systems collaborate to foster resilience, sustainability, and a deeper connection between cities and nature.

12. Reflecting on your transdisciplinary method combining AI, synthetic biology, computation, and architecture, how do you envision the evolution of design education or research infrastructure to support the next generation of material-led ecological architects?

Design education stands at the threshold of a paradigm shift. As artificial intelligence, synthetic biology, and computation converge, the next generation of architects must evolve from form-makers into system designers - mediators between the digital, the biological, and the ecological.

The design atelier or university studio of the future will no longer be a room of drawings, but a living laboratory where code and culture, material and metabolism, coalesce.

Here, matter is not an inert substance but an intelligent agent; architecture is not an object but an organism. This new pedagogy demands infrastructures that are hybrid and recursive - laboratories where algae grow beside algorithms, and prototypes become civic experiments.

Research is nothing but a form of ecological negotiation, and education is a rehearsal for cohabitation with the more-than-human world. Projects such as FundamentAI and Photosynthetica prefigure this evolution: they show that design, when coupled with living intelligence, can become an instrument of planetary care. In this new ecology of design, creativity is no longer the act of imposing form upon nature but the art of learning to think, build, and evolve with life itself.