What are the most exciting material innovations you’ve worked with in recent years at Renault, (and how do they align with the future of automotive design?)

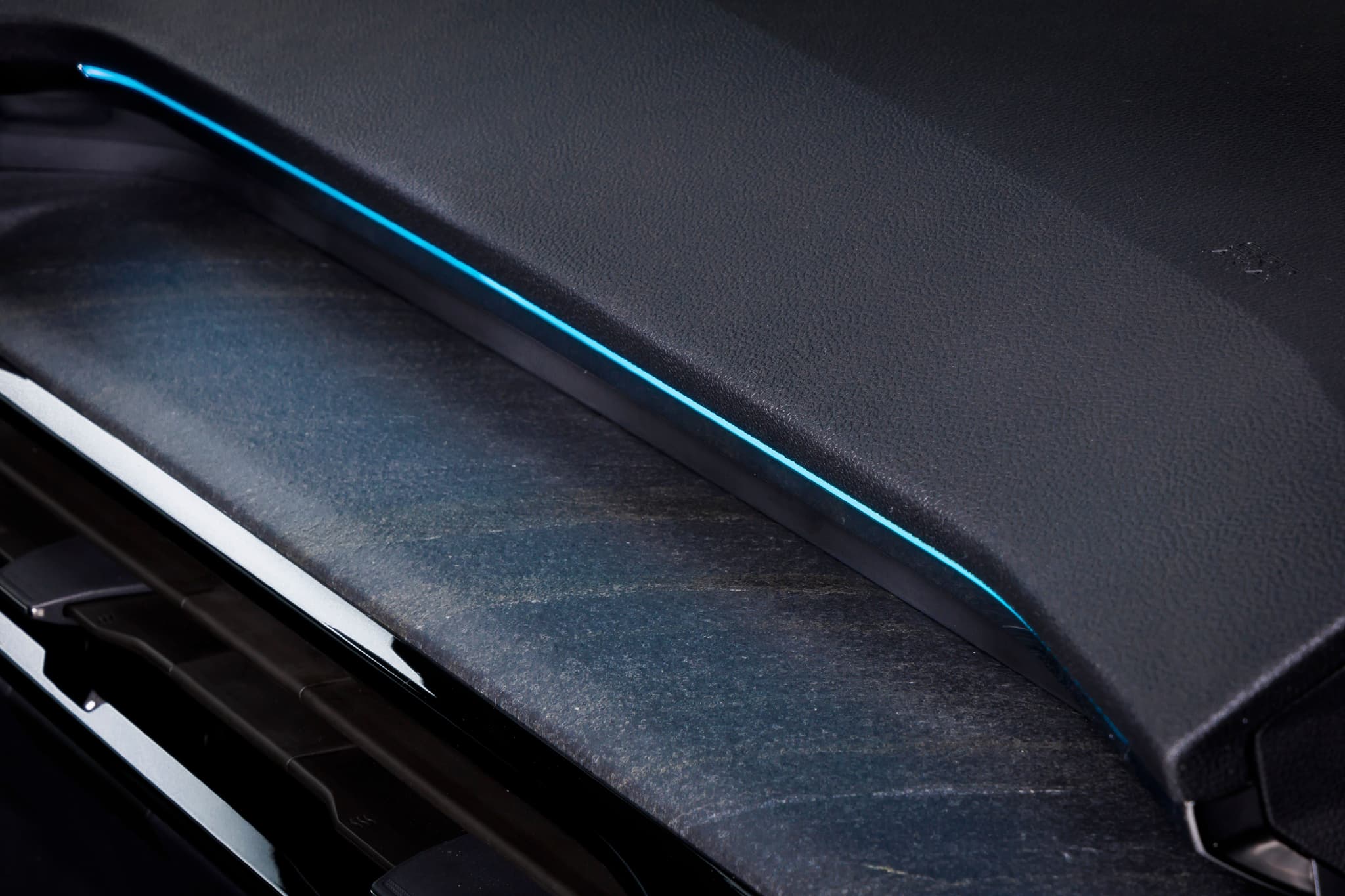

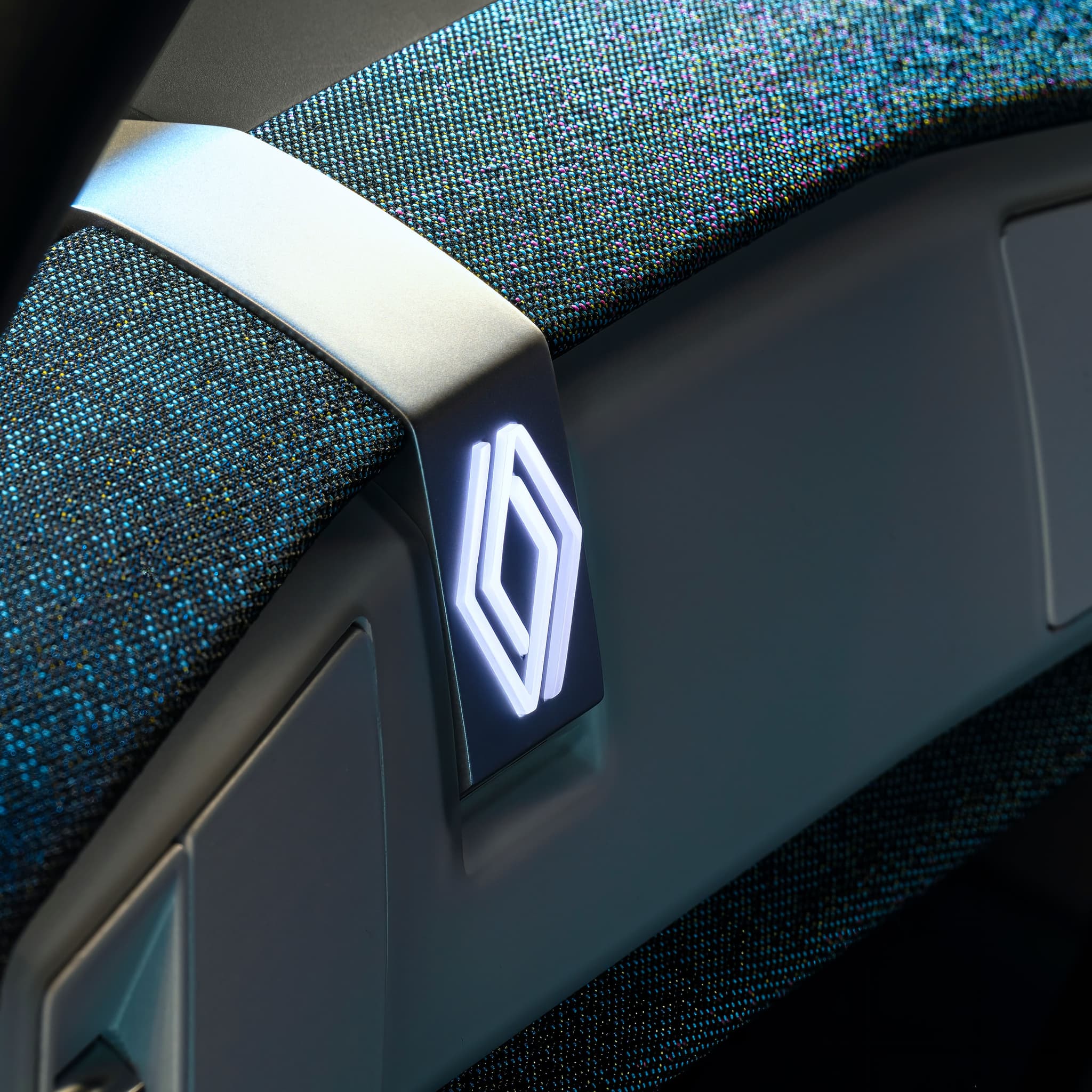

For Rafale, the vehicle which is the top of our range, we wanted to introduce authentic and new materials for interior of the mass-production series, such as cork or Slate Decoration pieces.We have also exploited light in an unusual way, in the form of a backlit logo positioned on the backrest of the front seats for Renault ‘s sport level called Esprit Alpine.These 3 examples show that the automobile is not subject to a form of eternal repetition, but it reinvents its codes by creating bridges with the world of housing.

With your background in weaving and fine art textiles, how has this expertise influenced material applications in car interiors or exteriors? Any notable case studies or Renault projects where this has come to life?

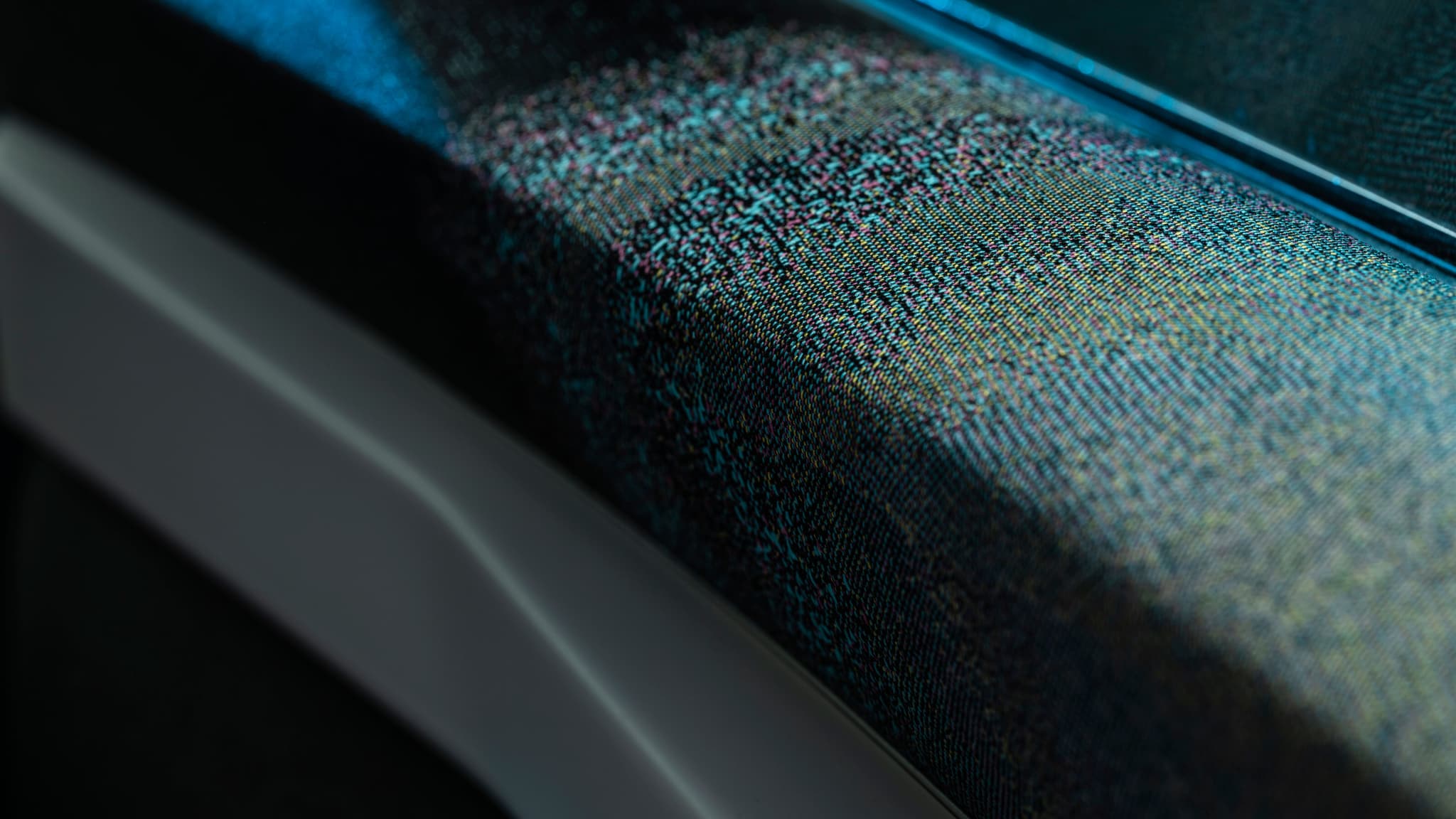

Textile practice has provided me with a way of searching for inspiration, combinations of colors, material textures, patterns & graphism, and surface qualities for both interiors and exteriors.

The most current example is the Rafale Esprit Alpine interior. One example of a unique color combination is seen in the triple-colored stitches, which refer to the French flag colors on the seats, steering wheel, and door panels.

3. How is Renault integrating circular material strategies? Are there commercially available bio-based, recycled, or closed-loop materials in Renault’s current models?

Recycled & bio-sourced materials are commercially available in current Renault vehicles. For example, for seats, 100% recycled textiles are already applied to our current production cars, and 61% recycled Alcantara in the Rafale’s Sport level. We started to introduce some bio-sourced contents in our PVC for the Sports level ranges. Emblème, a demo car developed in 2024 to maximize decarbonisation throughout its life cycle, introduces an example of closed-loop material. The seat polyester textile’s salvage waste is integrated into the polyester floor, making them mono-materials, which are all recyclable.

4. Electric vehicles emphasize minimalism and lightweight materials. How has this shaped your CMF strategies, particularly in texture and finish?

Take the example of the current MEGANE & SCENIC E-Tech Electric cars, where we have flexible wood decors that bring an aesthetic identity in line with our values of hospitality, comfort on board, and Renault's desire to offer warm, human-oriented interiors.

An example of lightweight material would be 3D printing used in the storage and customization elements of the R5 and R4 E-Tech Electric. 3D-printed surfaces are often line-meshed, influencing the tendency of visuals and finishes, which are often airy and meshed textures.

5. How have digital tools and AI (e.g., AI-powered material libraries, generative design) influenced your CMF design and material selection process?

Digital tools are definitely influencing CMF design. Our target with AI is to create original CMF images, immersive worlds, and textures.

Designers are always required to keep learning new tools to respond to the sensibility of new generations. For the design and selection process, digitally manipulated design ideas, colors, textures, and presentation formats are becoming more and more prevalent.

6. What under-the-radar CMF trends (e.g., dynamic color-changing surfaces, tactile interfaces) do you see gaining traction by 2025? Are there any Renault-led innovations in this space?

In the Renault Emblème demo car, you will see our latest CMF trends, such as color-shifting surfaces and tactile interfaces. This type of vehicle helps us showcase ideas and new development processes aimed at eventual production applications.

7. Having been in the space for almost two decades, how has the CMF philosophy and material selection evolved, according to you? (Could you point to specific materials or design elements that best represent this shift?)

In the last two decades, I have seen two significant evolutions in CMF design, particularly in the last 10 years.

The first is the sustainability requirements. More than 10 years ago, designers focused on visual effects and brand identity as the main objectives. Now, integrating sustainability into the design strategy is inevitable and influences the visual outcome. Applying recycled materials was challenging in terms of price and visual appearance, but now these materials are considered standard. The next challenge is establishing a full loop of recyclability for automotive materials, as well as moving towards bio-sourced materials for integration in production.

The second is the integration of AI. The evolution of digital tools has been rapid in the last five years, moving from 2D to 3D, from moving images to AI. These technologies offer more facilities and opportunities in the development of projects that serve our strategy and our customers. The understanding of objects and sensibility for visual effects has evolved and is now more digitally expressed. The CMF challenge lies in interpreting digital influence into physical objects.