Key Points

- Plant-based SAP tuned for hygiene, food pads, and agriculture; designed to retain absorbency under pressure and in ionic fluids.

- Drop-in particle size and flowability target existing hygiene manufacturing lines.

- Optional natural antibacterials extend shelf life for food packaging without petro-chemicals.

- Biochar + SAP pairing aims to improve soil water holding and nutrient retention; field trials underway.

- Roadmap explores packaging, refrigerated goods, and medical uses where petro-SAPs dominate.

Full interview with Namalab

Can you elaborate on the key challenges and breakthroughs in developing a fully plant-based, compostable superabsorbent polymer (SAP) that maintains high-performance absorbency comparable to traditional polyacrylate-based SAPs?

The key challenge in developing a fully plant-based, compostable superabsorbent polymer (SAP) that maintains high-performance absorbency comparable to traditional polyacrylate-based SAPs lies in meeting the diverse requirements of various industries.

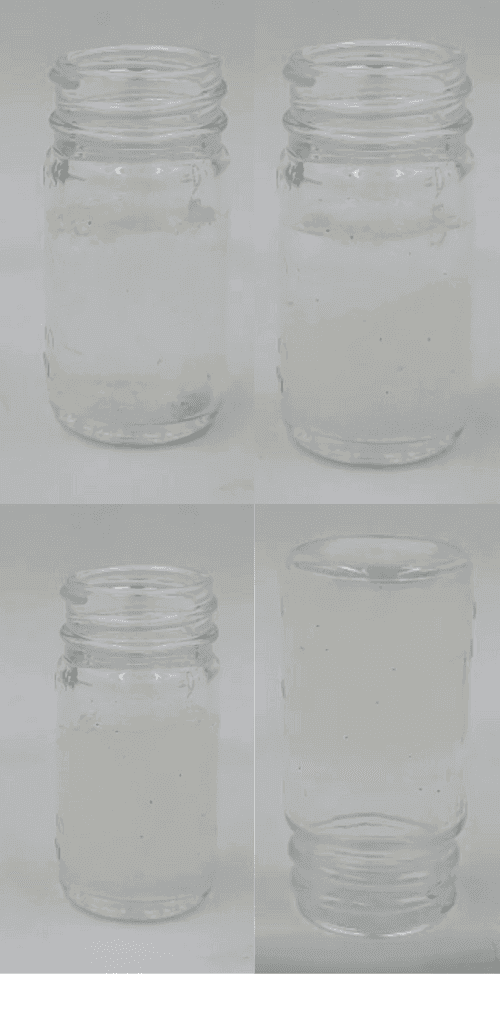

Apart from absorbing large amounts of water, SAPs for applications such as disposable diapers and hygiene products must retain their absorbency under external pressures and in the presence of ions found in bodily fluids.

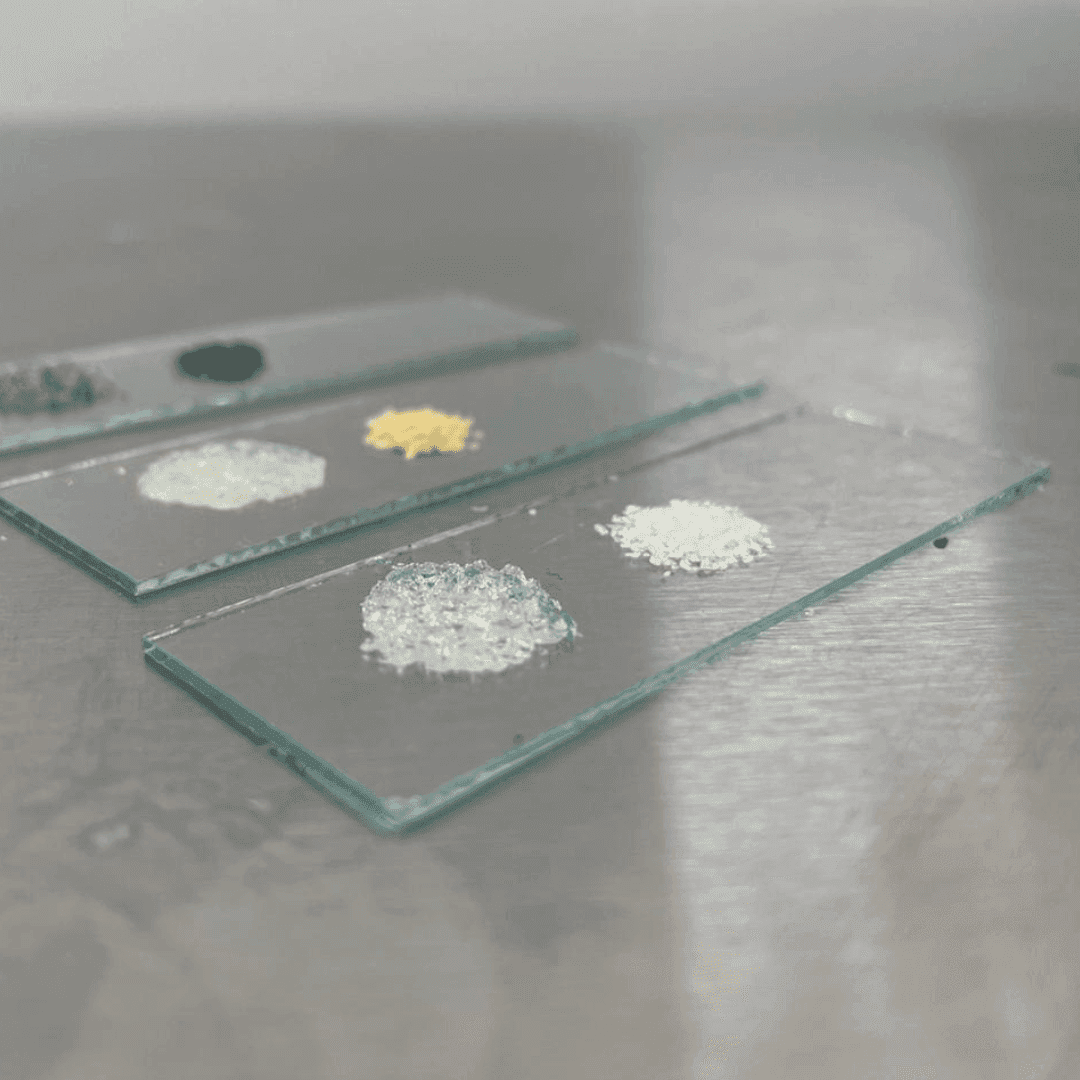

Similarly, SAPs used in moisture retainers for crops and food absorbent pads require different properties. At Namalab, we've developed core technology to customise NamaSAP (our proprietary material) for each application, ensuring they meet industry-specific requirements while remaining scalable and economically viable.

What specific properties of your proprietary NamaSAP make it an effective drop-in replacement in existing manufacturing lines for hygiene products, without necessitating significant modifications?

In our journey to develop NamaSAP, we were inspired by a real market necessity identified within hygiene companies actively seeking alternatives to synthetic SAPs.

Recognising the challenges, we set out to create a solution that not only met eco-friendly standards but also seamlessly integrated into existing production lines and processes. To achieve this, we meticulously considered the key properties that had long made synthetic SAPs seemingly irreplaceable, such as particle size, absorption capacity, flowability, and so on. By ensuring NamaSAP's compatibility with existing manufacturing lines, we aimed to facilitate a smooth transition to sustainability for hygiene companies seeking alternatives to synthetic SAPs.

How does the introduction of natural antibacterial agents into NamaSAP enhance the functionality and market applicability of compostable food packaging solutions?

The introduction of natural antibacterial agents into NamaSAP enhances the functionality and market applicability of compostable food packaging solutions in several ways. Firstly, by incorporating natural antibacterial agents, NamaSAP can actively inhibit the growth of harmful bacteria, fungi, and other microorganisms, thereby extending the shelf life of packaged food products. This not only ensures food safety but also reduces food waste, a critical concern in today's sustainability-focused market.

Furthermore, the addition of natural antibacterial agents enhances the overall hygiene and cleanliness of the packaging, providing consumers with greater confidence in the safety and quality of the products they purchase. This is particularly beneficial in applications where food products are stored or transported for extended periods, such as in the case of fresh produce and meats.

Additionally, the use of natural antibacterial agents aligns with consumer preferences for eco-friendly and sustainable packaging solutions. By leveraging renewable and biodegradable materials, NamaSAP with natural antibacterial agents offers a compelling alternative to traditional petroleum-based packaging materials, catering to the growing demand for environmentally responsible packaging options.

Overall, this innovation has significant potential in the hygiene sector, particularly for products such as diapers and feminine pads. By incorporating natural antibacterial agents, these hygiene products can provide enhanced protection against bacterial growth, ensuring better health and safety for users while maintaining an eco-friendly, compostable nature. This dual functionality positions NamaSAP as a versatile and valuable material across multiple industries.

What role does biochar technology play in your agricultural solutions, and how do you ensure its integration with NamaSAP enhances water and nutrient retention without compromising crop quality?

Biochar acts as a soil amendment, improving soil structure and enhancing its water retention capacity. By incorporating NamaSAP, which also possesses excellent water-absorbing properties, the synergistic effect results in significantly improved water retention in the soil, even during dry periods.

This helps to mitigate the impact of drought and water scarcity on crop growth and productivity. Additionally, biochar has a high surface area and porosity, enabling it to adsorb and retain nutrients in the soil, preventing leaching and runoff. By incorporating NamaSAP, which acts as a carrier for nutrients and enhances their availability to plants, essential nutrients are effectively retained in the root zone, promoting healthy crop growth and minimising fertiliser loss.

Through careful formulation and testing, we ensure that the integration of biochar with NamaSAP does not compromise crop quality. Our research and development process focuses on optimising the balance between water and nutrient retention while maintaining optimal soil aeration and microbial activity. This ensures that crops grown in soil amended with NamaSAP and biochar exhibit superior quality, including improved yield, nutritional content, and resistance to environmental stressors.

We are starting to conduct extensive field trials and validation studies to assess their performance under real-world conditions. These trials allow us to fine-tune our formulations and application methods to maximise efficacy while minimising any potential adverse effects on crop quality. Overall, the integration of biochar technology with z in our agricultural solutions represents a holistic approach to soil and water management, aiming to enhance crop productivity, sustainability, and resilience in the face of climate change and environmental challenges.

Looking towards the future, how does NamaLab plan to expand the application of its compostable materials technology beyond the hygiene and agricultural sectors?

NamaLab plans to expand the application of its compostable materials technology beyond the hygiene and agricultural sectors by exploring new markets and industries where sustainable solutions are in demand.

This expansion strategy involves several key initiatives. Firstly, NamaLab will invest in research and development to innovate new compostable materials and products tailored to the specific needs of different industries. Secondly, strategic partnerships with companies and organisations across various sectors will be sought to co-develop and commercialise compostable solutions.

Our deep understanding of biopolymers allows us to tailor new solutions that can replace superabsorbent and other types of polymers in the industry. Foreseen innovations aim to apply our technology to sectors such as packaging, refrigerated goods, and medical applications.