Key Points

- Recycled build: proprietary extrusion bonds post-consumer PET with recycled glass to deliver stone-like slabs with high mineral content and robust performance.

- Verified safety: VOC-free process (Greenguard Gold) uses physical mixing instead of polyester/acrylic resins, improving indoor and worker safety.

- Circularity in practice: waste slabs are crushed to granulate and re-fed into new batches; recyclability now stated at 99% with EPD and ISO 9001/14001/45001 in place.

- Material efficiency: continuous extrusion cuts raw inputs by ~70%, enabling thinner 6–8 mm products with strong impact resistance and lower cost.

- Design + pipeline: marble/terrazzo looks via sublimation printing; roadmap targets better stain/scratch/fire resistance and >85% recycled content as EU rules push minimum recycled material.

Full interview with Sustonable

1. Can you explain how Sustonable’s composition was developed and how it impacts its functionality and aesthetic qualities?

We started with quartz to offer a sustainable alternative to engineered stone by replacing the polyester resin with post-consumer recycled PET. We developed a proprietary extrusion process to achieve this. In recent years, we've focused on replacing quartz with recycled glass. The product retains the look and feel of stone and has strong properties due to its high mineral content.

2. What were the key challenges in sourcing and processing recycled PET bottles and glass, and how did you overcome them?

Recycled raw materials are not as readily available as virgin ones, and it's more difficult to maintain color stability. We addressed this by working closely with suppliers and providing them with precise specifications. We also set clear expectations with our customers about the natural variation in color that comes with using recycled inputs.

3. How does your production process ensure safety and sustainability without using VOCs or toxic chemicals?

Our Greenguard Gold certification validates that our process is VOC-free. This is because it's a physical mixing process of recycled PET and glass, unlike the chemical processes used in traditional engineered stones with unsaturated polyester or acrylic resins. The absence of toxic emissions makes it safe for indoor use, workers, and the environment.

4. How do you assess and track the environmental impact of your production, and what steps are you taking to improve sustainability?

We’ve revised the recyclability claim to 99%, acknowledging a small unavoidable margin. We have an Environmental Product Declaration (EPD): EPD-IES-0022352:001, and follow ISO 9001, 14001, and 45001 standards to measure quality, environmental impact, and workplace safety.

5. How does the recycling process work in practice, and how is material integrity maintained through cycles?

Sustonable waste is collected, crushed into granulates, and reintroduced into new batches of raw materials, including recycled PET and glass. Each production batch is performance-tested, ensuring that material integrity is preserved even after recycling.

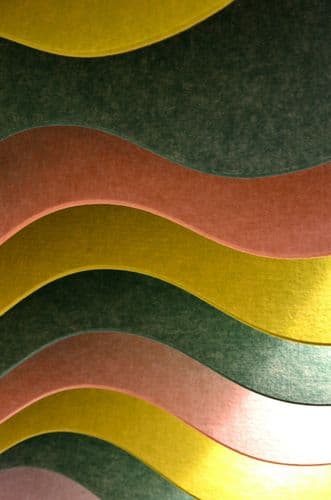

6. How are different aesthetic effects such as marble or terrazzo achieved in Sustonable surfaces?

We use sublimation printing: the design is printed on paper, applied to the slab, and then sublimated into the surface through heat. This process allows flexible and customizable designs, ranging from stone to terrazzo effects.

7. How did you achieve a 70% reduction in raw materials, and what are the performance and cost implications?

Thanks to our continuous extrusion process, we use 70% fewer raw materials compared to engineered stone. Recycled PET contributes to high impact resistance, allowing us to produce thinner products (6–8 mm vs. 12–20 mm). We also require less slab calibration, improving cost-efficiency.

8. What is the future of recycled materials in high-end design, and how does regulation play a role?

The Ecodesign for Sustainable Products Regulations under the EU Green Deal will enforce minimum recycled content in interior materials. We believe sustainability will become a key driver, even in the luxury segment.

9. What innovations are on the horizon for Sustonable?

We’re improving stain, scratch, and fire resistance to match ceramics and porcelain. We're also enhancing our design offerings, including Mosaic products and vanity tops, and are far along in developing a product with >85% recycled content.