Key Points

- Kombucha cellulose as “leather”: Jun’s team grows bacterial cellulose from tea and sugar using a SCOBY, then dyes and oils it to create a fully plant-based, home-compostable textile—no plastics, no animal inputs.

- The durability trade-off: Purely biobased, compostable sheets are vulnerable to rain and humidity; that fragility is the flip side of true biodegradability.

- Calling out the status quo: Most “vegan leathers” rely on fossil-based binders/coatings for performance; she argues this distracts from the heavy environmental and ethical costs of animal leather, and backs a move to plant-based coatings as they mature.

- Living materials + customisation: 3D scanning/printing enables custom orthotic insoles grown with mycelium; keeping organisms “alive” could unlock sensing/self-repairing behaviours beyond today’s inert composites.

- Decentralised, low-tech ethos: Fuses craft (sewing, embroidery) with affordable 3D printing to localise production, shorten supply chains, and keep techniques accessible—while exploring bio-derived pigments and “smart” microbes for next-gen textiles.

Full interview with Poorva Shrivastava

How does biotechnology play a role in your textile design process, particularly in developing vegan leather from bacterial cellulose?

The fermentation of bacterial cellulose has been done for decades, such as in East Asia, to make nata de coco, a jelly-like dessert. Biotechnology itself, when we come to think of it, is an ancient practice, from beer to kimchi, and can be understood as ‘using microbes to make things we want’.

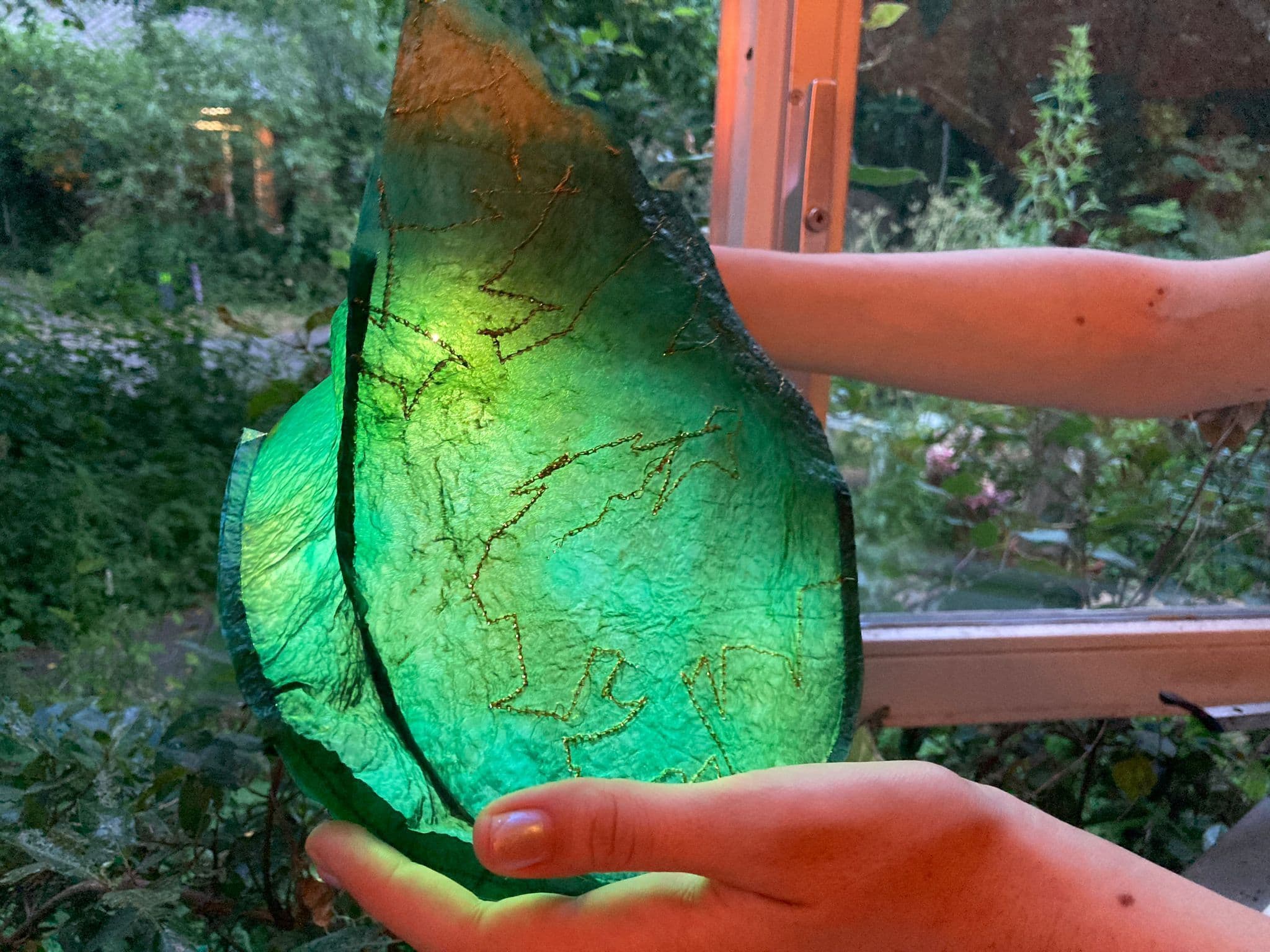

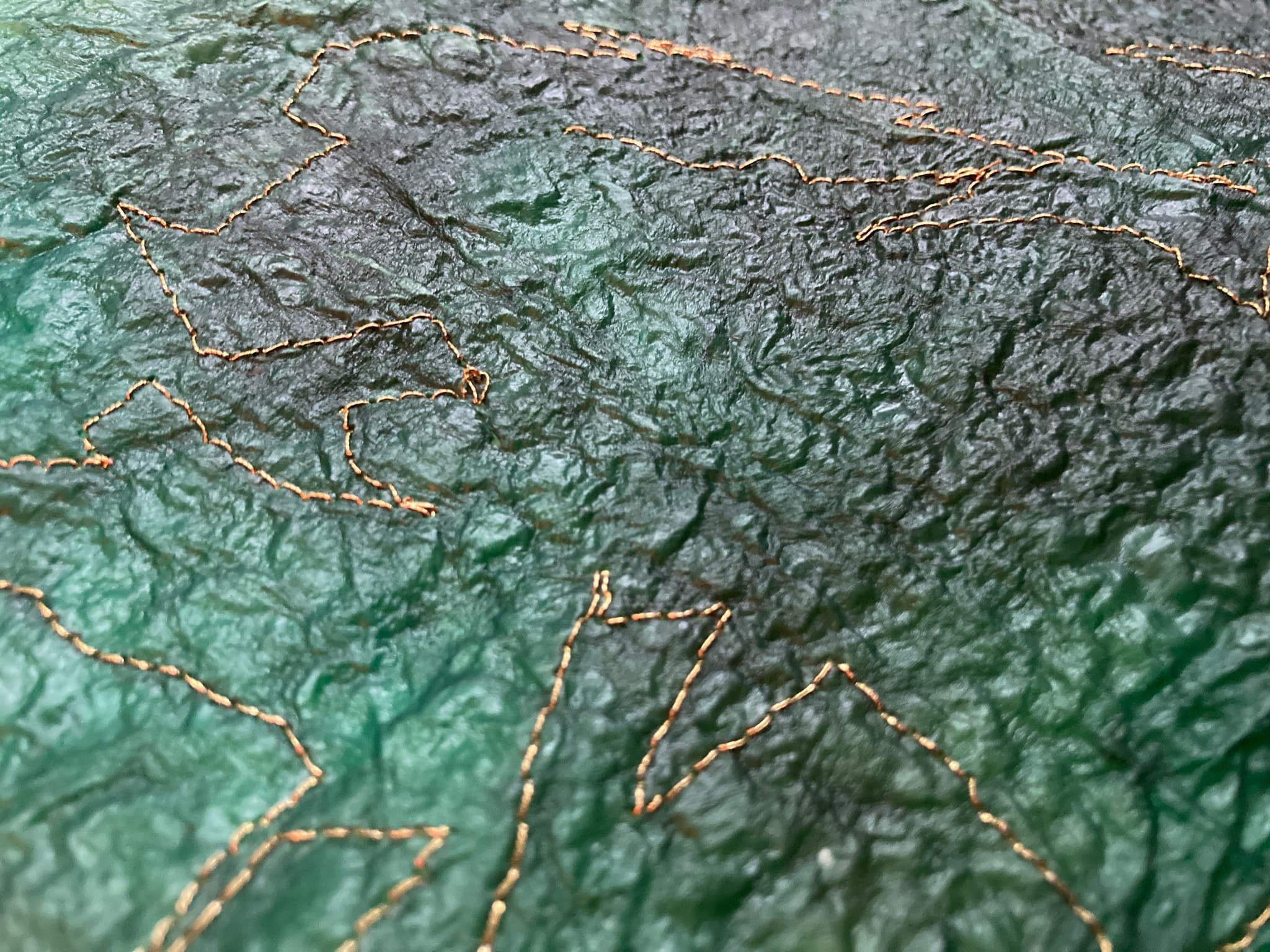

MycoPunk, our collective, came together with a vision to share knowledge and simplify biotech so that people can make what they want with the things they have around them, like a handful of microbes. So when we make bacterial cellulose textile, the biotechnology is quite simple: we start with a sweet black tea, which is ‘eaten’ by a kombucha SCOBY (symbiotic culture of bacteria and yeast). In a few weeks, the bacteria ‘spin’ a dense, strong mat of cellulose to house themselves in. We harvest, dye, oil, and dry this sheet of cellulose to get a leathery textile (which isn’t ‘real’ leather at all, as no animals are killed in this process!).

The microbes do most of the work; the art of working with microbes is to understand their rhythm and provide conditions for them to thrive. What biotechnology does for us is optimize this process, make it faster, or make it take place in more efficient conditions.

Vegan leather has often faced criticism for relying on plastic-based materials. How does your bacterial cellulose leather compare in terms of sustainability?

Our bacterial cellulose leather is completely animal-free, biodegradable, and compostable. There isn’t a single synthetic ingredient, and you could even eat it! It has a very low environmental footprint: it grows at ambient temperature and conditions and uses only tea and sugar to grow. Not resting on our oars, we are trying to replace sugar with sugary waste streams from the horticultural industry.

We dye the material with natural ingredients like hibiscus flowers, turmeric, the invasive nettles that grow in our garden, or food colouring. To make it water resistant, we coat it with a mixture of plant oils and waxes, but these types of coatings help only to an extent. The material doesn’t hold up very well against rain or extended humidity. This is predictable.

Our findings just reflect a wider tension in the biomaterials space. If a material degrades in your compost bin, then it is probably not very resilient against the elements, and vice versa. If it is extremely tough, then good luck chucking it in your compost bin. It’s a tightrope that a lot of us in the biomaterials industry are trying to navigate.

However, the wider debate about vegan leather needs to be analyzed holistically. We’ve seen an explosion of startups making leather alternatives from biobased sources in the last few years. Accompanying this biomaterials revolution is a knee-jerk dismissal of vegan leathers from some quarters.

The skepticism arises from the fact that the vast majority of vegan leather companies use fossil-fuel-derived binders and coatings, even if the base material is plant-based, to confer functionality like waterproofing, which purely plant-based materials tend to struggle with because of the nature of their microstructure. These types of mixed materials are often criticised because they are very difficult or even impossible to recycle in our current system - and thus, we should stick to animal leather.

In my view, this argument is misinformed and misses the point at best. At worst, though, it is a distraction from the realities of the animal leather industry. The carbon emitted and the environmental destruction wreaked by leather tanning are extremely well-documented and decimate entire ecosystems. It’s a shocking industry. Adding to this is the suffering and deaths of people in the industry exposed to carcinogens and toxins.

The environmental and social destruction caused by animal leather has been proven time and again, but I would like to underline another aspect that is very often sanitized when we talk about biomaterials: the sheer horror and entitlement of killing a sentient, intelligent being because we as humans feel entitled to their flesh and skin. It’s very depressing. The ethical concerns alone dwarf everything else for me. To proponents of animal leather, I would say there is nothing environmentally or animal-friendly about leather. The replacement of plastic coatings and binders is a technological challenge many researchers are working on.

I look forward to the day that plant-based binders and coatings become accessible and functional, and when that day comes, companies can ‘plug in’ the plant-based coatings and simply do away with the synthetic ones.

Can you discuss the benefits and challenges of working with fungal mycelium in your design and manufacturing processes?

The benefit and the challenge are the same: that we are working with a living organism! Evolution has distilled millions of years of knowledge in fungal mycelium. It is a living, sensing, adapting, and self-repairing material - functionalities that man-made items simply cannot beat so elegantly. This incredible intelligence can be seen all over the world. There are some types of fungi thriving in the radiation left over from Chernobyl. They express melanin, the same pigment that we humans also have, to protect themselves from radiation. So fungi are intelligent, really intelligent.

But this brings us to the flip side — they have a mind of their own, and it’s not easy to manipulate them into behaving the way we want. With living organisms, you really have to work with them in collaboration. When we try to impose our will on them, such as by heating and killing the mycelium, we also lose a lot of their intelligence. I’m not saying that sterilizing mycelium composites is a bad idea - after all, it allows us to use mycelium materials for consumer applications like biodegradable packaging or insulation panels. These are some of the most proven commercial applications of mycelium materials to date.

However, from a mechanical strength viewpoint, the mycelium composites we have been able to create so far are not very functional. They can be quite brittle and aren’t strong. I work in a bio-inspired materials lab, and we are increasingly realizing that by keeping the mycelium alive, we can tap into their unparalleled sensing (and responding) capabilities. That, in my opinion, is much more interesting and opens up a whole untapped world of possibilities.

Apart from their intelligence, I see a huge opportunity in the existing mushroom-growing industry. The Netherlands, where we are based, is a big mushroom producer in Europe — this means that a lot of the infrastructure to grow mushrooms for food is already built and running. In my work, I always try to close loops. So, a lot of our early experiments with growing mycelium were done on bags of spent mushroom substrate from a friend who has a local gourmet mushroom business. The spent mushroom substrate was a ‘waste’ output of their process but was a valuable input for ours. This is such a ripe opportunity for collaboration between existing mushroom producers and upcoming mycelium material producers. Organic collaborations, just like in nature.

How does 3D printing enable customization in your orthotic insole production? What benefits does this bring to the user?

I’ve suffered from stabbing, sharp pain in my feet since I was a child. I have terribly flat feet. At some point, we decided to try to grow an orthotic insole that perfectly fit my flat feet using mycelium. So we 3D scanned my foot, 3D printed a mold, and grew a mycelium insole that fit the geometry of my foot exactly. In the future, we want to repeat this process without the mold — we want to directly print the footsole itself, customized to people’s feet.

3D printing is brilliant and beautiful because making five slightly different pieces of something is as easy (and cheap) as making five identical pieces of the thing. In other manufacturing methods like milling or injection molding, it is always cheaper to create copies of the same item. Customization is expensive.

However, there are so many situations in which customizability is amazing for the user! Think of products that would benefit from being made exactly to a person’s body, like shoes, dental work, orthopedics, or prosthetics.

In what ways does decentralized manufacturing, such as 3D printing, contribute to more sustainable production methods?

We often assess things from a capitalist, market-driven lens. But what if this is the wrong frame of reference? Can we imagine a completely different future? What if we valued different things? Things like building things together, caring about our communities, sharing resources and knowledge with each other, and sprouting grassroots solutions help foster a sense of community ownership.

Imagine if every school in the world had a 3D printer. Kids with bright solutions to the problems they face in their communities would have the freedom to take ownership and innovate. 3D printing bypasses the need for outrageously expensive manufacturing equipment. It has the potential to shorten supply chains and open markets up for smaller competitors with less investment behind them. I personally have a couple of printers at home, bought for under a few hundred euros.

A large part of the 3D printing phenomenon has been this homegrown, open-access ethos, which is quite a paradigm shift from the status quo. 3D printing is subversive and will lead to a more open and fair future. Shifts in production trends will be made by small businesses, locally, and not in the board rooms of multinational companies or venture capitalists.

At MycoPunk, we cannot wait for a bottom-up approach to organizing our economy. The global system that we call capitalism is incredibly efficient at generating wealth, but it cannot give us the most basic of things — human happiness. A more local, decentralized, and “bottom-up” approach is the only way to allow people to share successes directly and live happily long-term.

What are the biggest challenges and opportunities you've encountered in developing biobased materials for your products?

The biggest challenge with our kombucha leather or mycelium foot soles has been making them functional for consumer use. They’re completely biodegradable and very sustainably produced, but this is also precisely why they’re more susceptible to the elements. They cannot yet do what plastic does.

This is not surprising; plastics are wonderful material property-wise and behave how we want them to behave, except for the annoying fact that they don’t break down. But we have had decades of research go into fossil-derived plastics. The biobased, functional materials field is quite nascent in comparison. But this is also an opportunity to learn, innovate, and move forward.

How do you think alternative materials like bacterial cellulose and fungal mycelium can change the future landscape of the fashion industry?

Hopefully, towards more environmentally sustainable materials that do not use animal products. I also wonder if we will start to consume differently. Maybe we will accept that our biobased shoes are not invincible and need regular upkeep. Maybe kombucha leather ‘oiling’ will become a regular ritual in our lives. In any scenario, to have a lasting impact, alternative materials need to be available to the masses and be affordable.

How do you blend traditional craft techniques with new technologies like 3D printing in your design process?

We embrace a pragmatic approach to manufacturing. We always choose the easiest way to get to our goal, using methods available locally and at a low cost. So when I started producing bacterial cellulose sheets, it was the obvious choice to ask my housemate Clara, who is a seamstress, to stitch this vegan leather. She uses a sewing machine and does handiwork like stitching and embroidery. And why not? Traditional techniques are tried and tested, passed on through the generations for a reason.

Sometimes, those of us in the 3D printing and engineering field fall into this trap; we over-engineer everything. When all you have is a hammer, everything looks like a nail. It’s a funny and recurring situation in my household. My partner is a 3D printing engineer, and his instinct is to print everything, even if it could be slapped together in a minute with a piece of wood and a spot of glue.

But it’s important to keep things accessible and simple. I know that it isn’t compatible with the current capitalistic system. I experienced it in my career when I was trying to create a startup in rural India in the water sector. Looking back, I realize that the spirit, the beating heart of my work, was never the ‘startup’. It was sharing knowledge with people so that they could take ownership of their own well-being by making the things they needed from what they had around them.

In this case, it was water filters to remove pesticides from drinking water. The filters used biochar, a type of activated carbon made from local, woody invasive species. I couldn’t sustain my work because grassroots work is not considered ‘sexy’ enough to support. It comes from the ‘tech bubble’ attitude. Development aid organizations, just like venture capitalists, make shrewd choices to invest in over-engineered, ‘techy’ solutions because they hope that these companies will give them returns on their investment. But are these solutions easy for people to replicate or own? Are they accessible to the communities they claim to help? The long-lasting, radical, liberating change will never come from knowledge and wealth remaining concentrated in the hands of the few, especially for people in the Global South.

Why do I mention all this? Because it returns to the question of why we use traditional techniques like sewing, stitching, and embroidery, despite being 3D printing enthusiasts. We could have built a robot to sew the pieces of leather together — but this would have been engineering things for the sake of it. We had a human friend with the skills we needed, and it made perfect sense to collaborate with Clara. As we look to the future, we shouldn’t forget the wealth of traditional knowledge and skills we have inherited. Keep things easy; keep them accessible.

What emerging trends do you see at the intersection of biotechnology, textile design, and sustainable fashion?

A promising direction is to use 3D printing to create custom articles, like shoes or orthotics. Something I’m personally very excited about is using biotechnology to engineer microorganisms to create sustainable dyes and functional textiles.

Think of natural pigments secreted by fungi, algae, or bacteria or a ‘smart’ bacterial cellulose jacket that can respond to a sunny day by expressing melanin to block radiation, or mycelium foot soles which can expand in size as a child grows or repair themselves. Just thinking about the possibilities gets my brain buzzing!