Key Points

- AI, multi-omic platform selects fish-native proteins, then validates them via targeted in vitro and in vivo assays

- Lab-scale fermentation already reaches >1–1.5 g/L; scale-up targets 75–100 L reactors with >1 g/L

- Oral delivery via microencapsulation and post-extrusion coating protects proteins to achieve >80% survival in challenge tests

- Supplier filters include GMP, batch consistency and LCA-backed claims; solutions are indexed on efficacy and environmental impact

Full interview with AQUIT

1. AQUIT’s preventive treatments for fish health use bioactive compounds instead of antibiotics. What criteria guided your selection of these ingredients, and how do you ensure they maintain efficacy across aquaculture conditions?

Fish possess a complex immune system equipped with various mechanisms to defend against foreign elements such as pathogens. In this context, our approach involved generating and administering the fish’s own immune components to enhance their ability to respond to these pathogens.

These components are proteins that play a key role in modulating and regulating the innate immune response in fish. Consequently, when administered, they act in a “natural” manner, activating the fish’s defense signals and mechanisms.

2. Could you explain how your biotechnology platform identifies and validates compounds that enhance immunity in marine species? What role does bioinformatics play in refining these material inputs?

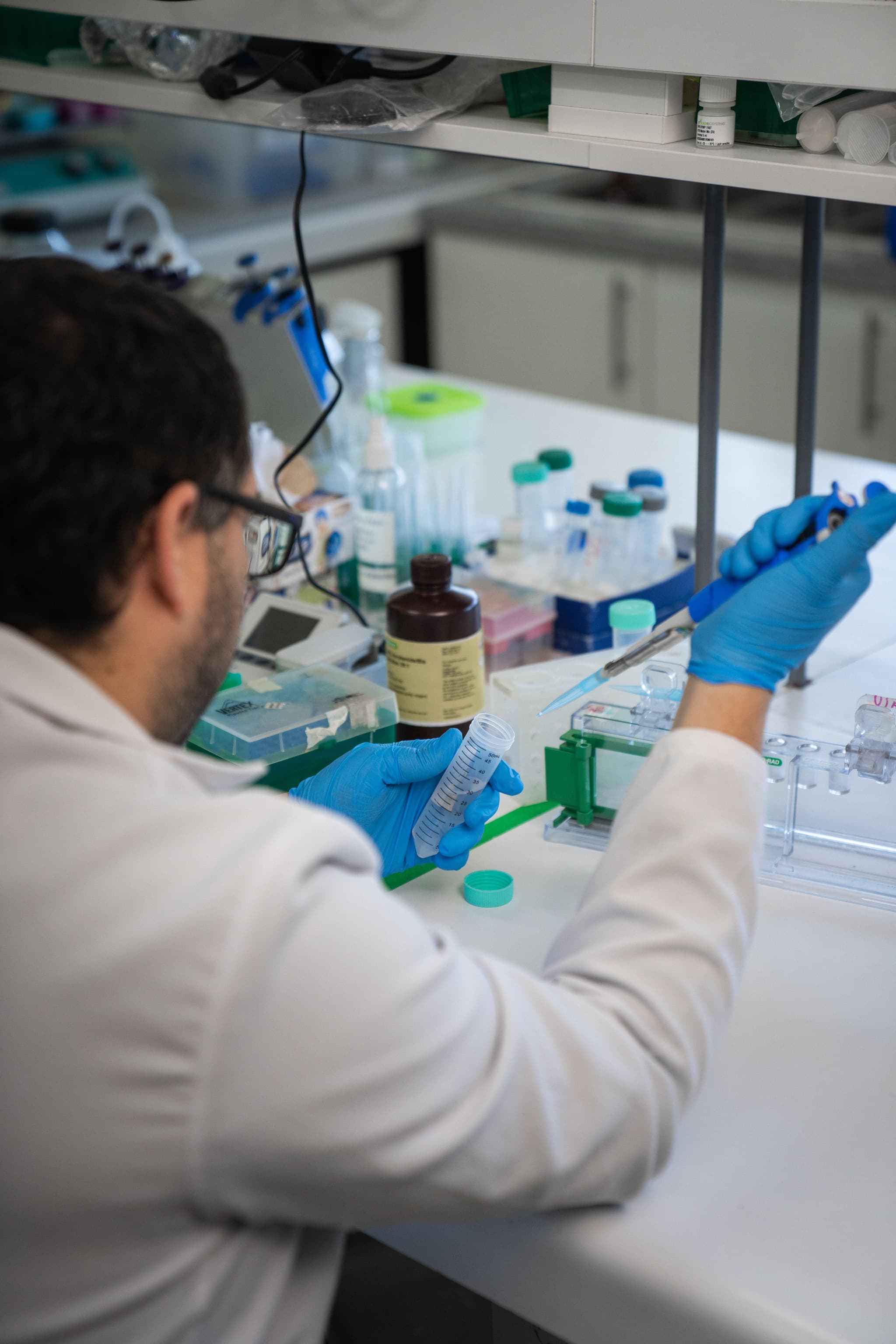

Our bioinformatic platform identifies and validates immunoactive compounds for marine species (e.g., salmonids, shrimp, tilapia) through an AI-driven, multi-omic discovery pipeline that integrates experimental validation with advanced bioinformatics, allowing us to optimize bioactive molecules that enhance immunity in these marine species. Using this multi-omic data and AI-driven modeling, we predict and refine candidates with high immunostimulatory potential, then validate their activity through targeted in vitro and in vivo assays. This iterative integration of computation and biology allows us to continuously improve the precision, efficacy, and sustainability of our compounds without disclosing proprietary design details.

Bioinformatics guides the refinement of our material inputs by integrating genomic, transcriptomic, and structural data to predict model, and optimize bioactive compounds before they reach the lab. With the support of AI technologies, it identifies conserved immune pathways, evaluates molecular stability and specificity, and simulates host–molecule interactions, ensuring each candidate is both biologically relevant and manufacturable. This computational layer accelerates discovery, reduces experimental uncertainty, and drives the rational design of next-generation immunostimulants for aquaculture.

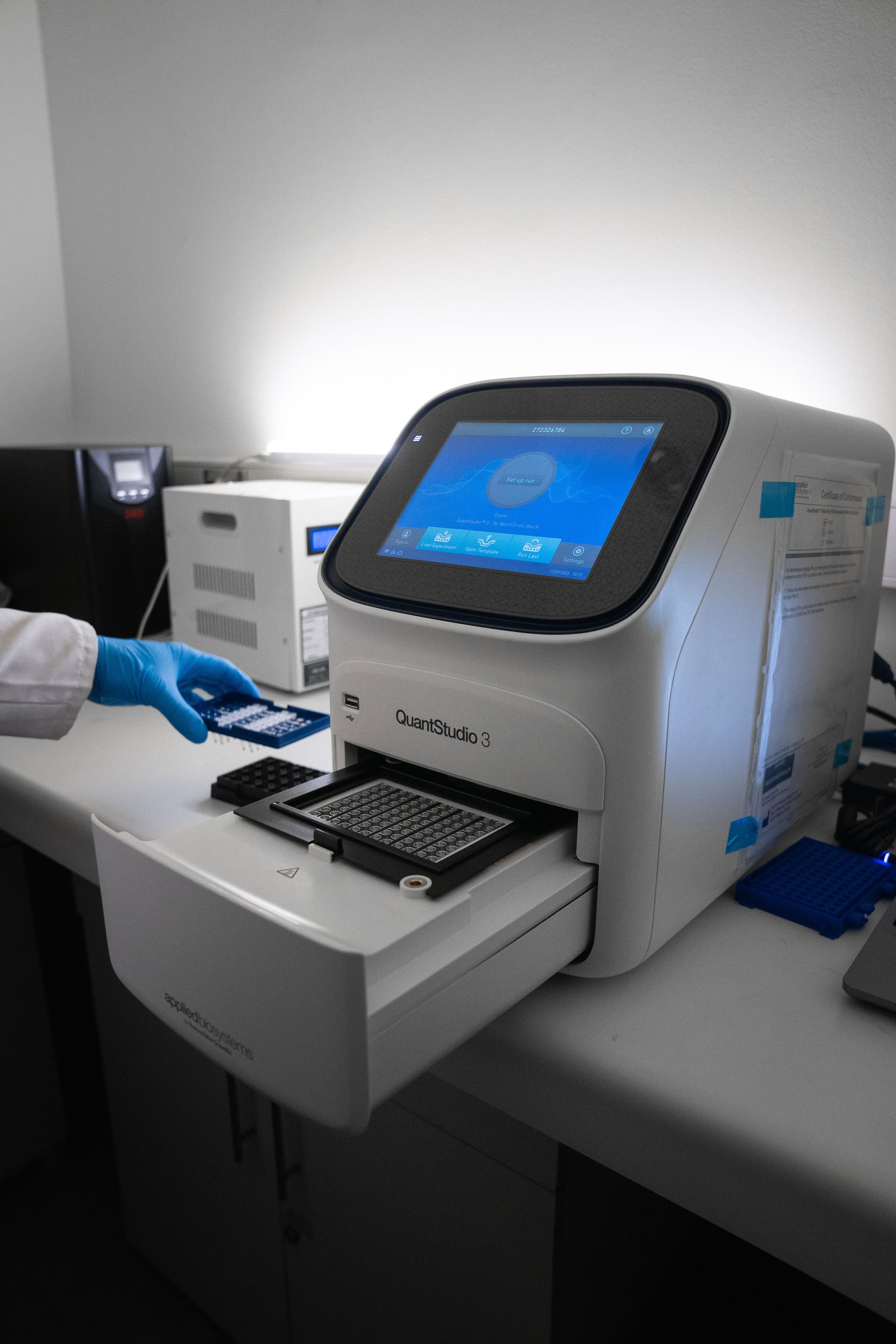

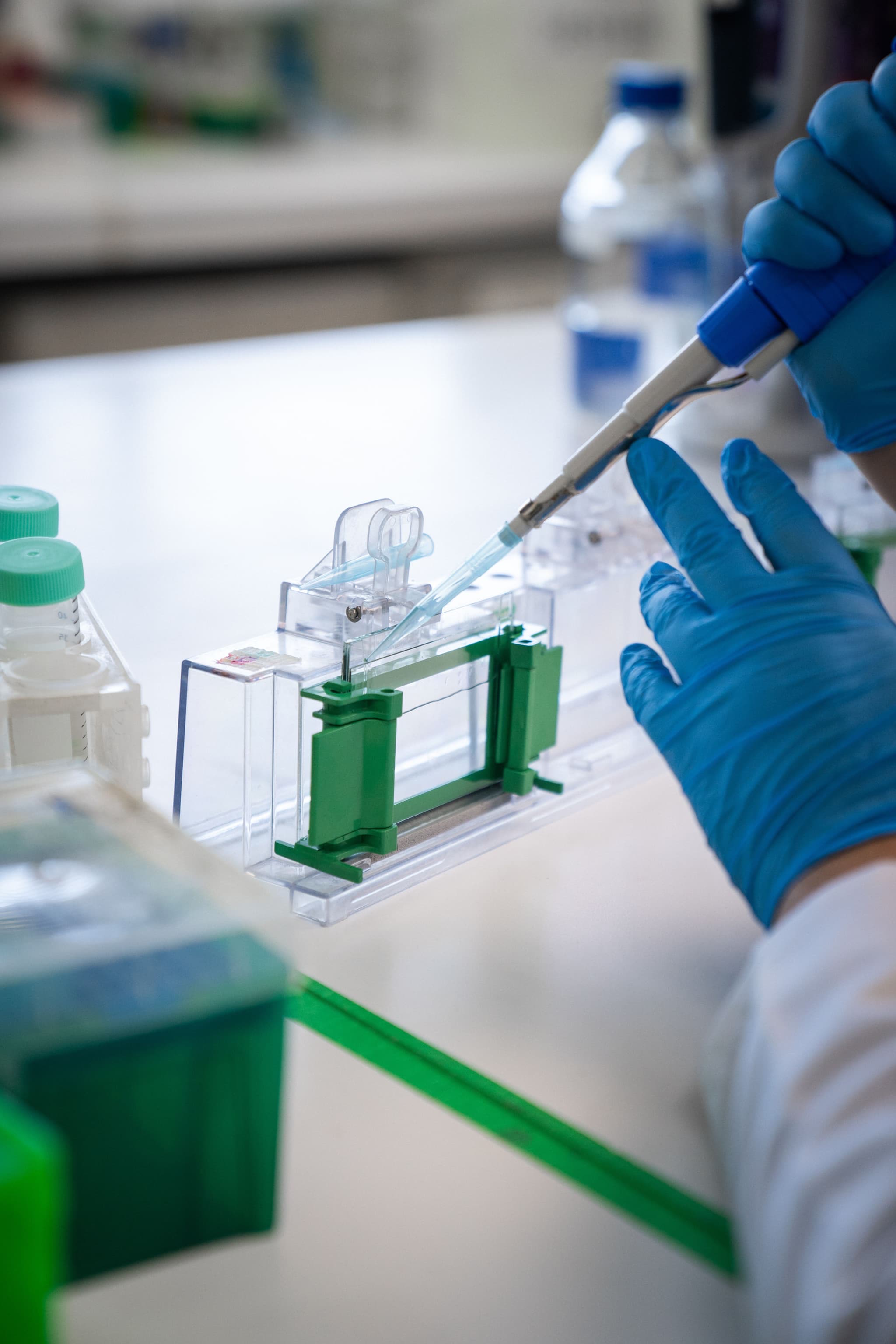

We have standardized an experimental strategy that enables the identification and production of recombinant proteins at laboratory-scale yields exceeding 1–1.5 grams per liter. The produced protein is subsequently validated in vitro by stimulating fish cells and assessing its effect through the expression of immune-related molecular markers through real-time qPCR. Bioinformatics has been key, as it allows us to apply filters when selecting our proteins, such as functionality, stability, antigenicity, etc.

3. Your product pipeline supports the replacement of conventional antibiotics. What material-level challenges did you face in achieving stability, bioavailability, and regulatory compliance simultaneously?

We are developing an encapsulation formula that will allow us to achieve protein stability and an efficient and effective bioavailability in the gut of the fish, where our protein takes action. Regarding regulatory compliance, we have been working with consultants who will help us register our product as a new feed additive.

4. In aquaculture, the delivery mechanism of any treatment is critical. How did you design your product to withstand variable aquatic environments without degrading or leaching?

Indeed, the delivery mechanism is a key aspect of this type of development. We have evaluated two approaches for administering our product: (1) intraperitoneal injection and (2) supplementation through fish feed. The first approach demonstrated that our product enhances the immune response, achieving survival rates above 80% against pathogens of commercial relevance in Chile.

Nevertheless, our efforts have primarily focused on developing an oral delivery strategy to minimize stress associated with procedures such as vaccination. In this context, we are optimizing a microencapsulation methodology designed to protect our protein from the acidic conditions of the stomach. Additionally, we are testing the administration of our product without encapsulation, applied post-feed extrusion, where we have recently obtained promising results. Regarding regulation, our proposal is to commercialize our product as a food supplement. Because it is a “fish-specific” protein, it does not present major regulatory challenges.

5. Many biotechnological treatments face scale-up issues. What adjustments were necessary when moving from lab-scale to commercial production, especially in the consistency and purity of your active materials?

We are currently at the stage of transitioning from laboratory-scale experiments to larger-scale production. The key objective is to achieve initial production in 75–100 L fermenters, with yields exceeding 1 gram per liter.

This has been accomplished in collaboration with strategic partners in Chile who specialize in precision fermentation. Regarding the application of the produced protein, we are validating its use in an unpurified form by incorporating it into fish feed after the extrusion process.

6. How does AQUIT evaluate supplier readiness and traceability for sourcing biomolecules, given the growing pressure to meet sustainability and health compliance benchmarks in aquaculture?

We will require potential partners with internal capabilities through verifiable Good Manufacturing Practices (GMP) certifications, extensive batch-to-batch consistency data, and demonstrated R&D support in the process of biomanufacturing.

Secondly, we could also evaluate the complete supply chain of the potential partners with tracking from raw material to final delivery, prioritizing the suppliers who substantiate their environmental claims with hard data, such as a Life Cycle Assessment (LCA). This rigorous, evidence-based audit will ensure that every supplier we partner with shares our unwavering commitment to quality, safety, and a sustainable future for aquaculture.

7. In your view, how should biotechnological solutions be indexed or compared when designers or sourcing teams are seeking high-performance, low-impact alternatives for fish health?

To effectively compare biotechnological solutions for fish health, designers and sourcing teams should use at least a dual-index framework that quantifies both Performance/Efficacy and Sustainability/Environmental Impact. This approach involves scoring different options, such as vaccines, probiotics, or genetic lines, across a range of standardized metrics. The performance index evaluates direct impacts on fish health and productivity, including disease resistance, survival rates, feed conversion ratio (FCR), and ease of application.

Concurrently, the sustainability index assesses the broader ecological footprint through metrics like life cycle assessment (LCA) data (e.g., carbon footprint, water use), the potential to reduce antibiotic and chemical use, and the impact on local biodiversity. Assigning scores to each metric allows a data-driven comparison for the selection of alternatives that could offer the best combination of high performance and low environmental impact.

8. What material innovations or discovery mechanisms excite you most in reshaping fish health solutions at scale, and what kind of infrastructure would accelerate that future?

As a company leveraging bioinformatics and fish immunology, we are most excited by the intersection of AI-driven multi-omic discovery and advanced oral delivery systems. We use AI to mine genomic and proteomic data to identify the precise, native functional proteins that resilient fish naturally use to boost growth and immunity. The key material innovation is then bioencapsulation, which allows us to wrap these proteins in smart microparticles, protecting them from the stomach and ensuring their targeted release in the gut via functional feed.

The kind of infrastructure that would accelerate our developments would be implementing our AI platform on a powerful cloud service platform with high computing power, implementing our own laboratory for the production and in vitro testing of the newly designed products, and performing quick proof of concept evaluations (PoC). Also, a mid-scale pilot plant to produce the proteins at scale to do first field trial pilots to validate the products in real commercial conditions.