Key Points

- 100% natural wood wrap, no chemicals or additives; fully compostable.

- One cubic metre of wood expands into 15–20 m³ of protective packaging with minimal energy and water.

- Spring-like structure delivers strong shock absorption; clients report near-zero breakage in peak periods.

- RAIKU reports LCAs showing >90% less wood, 98% less energy, 99.9% less water than paper/carton, and ~10× lower CO₂ footprint.

- FSC/PEFC-sourced inputs; scaling via new facilities and potential licensing, with customers feeding into R&D.

Full interview with RAIKU

How does RAIKU's wrap differentiate itself in terms of sustainability and protective capabilities from other eco-friendly packaging options currently available for bottles, ceramics, and cosmetics?

RAIKU is a cleantech company that has developed a breakthrough packaging material and its production technology to solve the massive pollution in the packaging industry. We will substitute plastics and other high-carbon packaging materials (bubble wrap, paper, cartons, bioplastics) with our 100% natural, compostable, beautiful, and shock-absorbing material.

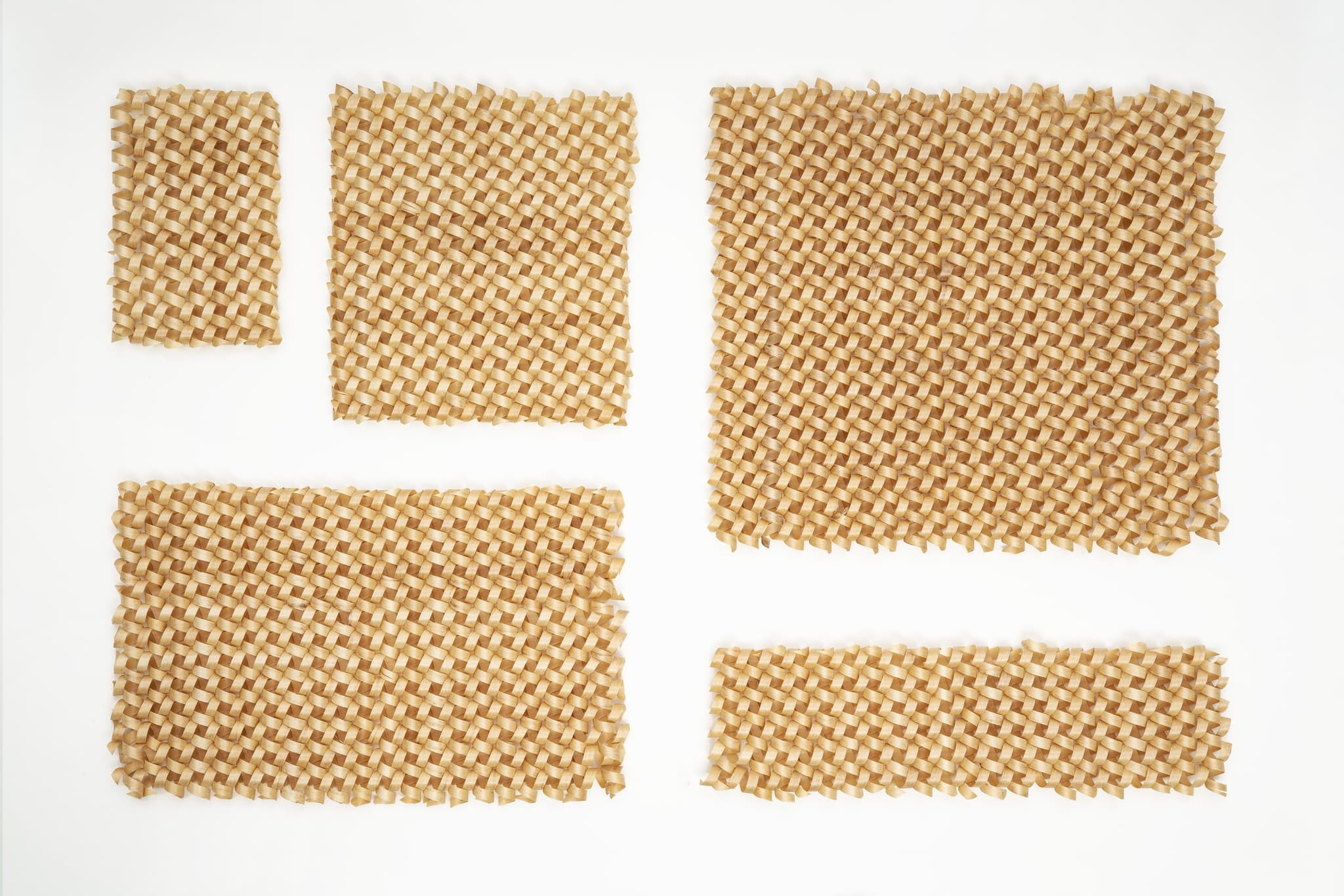

RAIKU’s packaging filling is made out of only one raw material, wood, and no chemicals or additives are used in the production. The raw material use is extremely efficient as we can turn 1 cubic metre of wood into 15-20 cubic metres of packaging. Combined with very low amounts of energy and water, we can offer one of the lowest packaging materials in the world, if not the lowest.

This is a great example of clean low footprint production, as well as a safe end life. It is very important because only 65% of packaging is being recycled in Europe, and even less in other parts of the world. This means millions of tonnes of packaging waste will end up in the wrong places for the next decades. Most of the packaging materials are composite materials that either don’t degrade at all or only under certain conditions being labelled ’biodegradable’. 100% compostability is needed for nature to turn these materials back to nutrients if we can’t manage to recycle them ourselves.

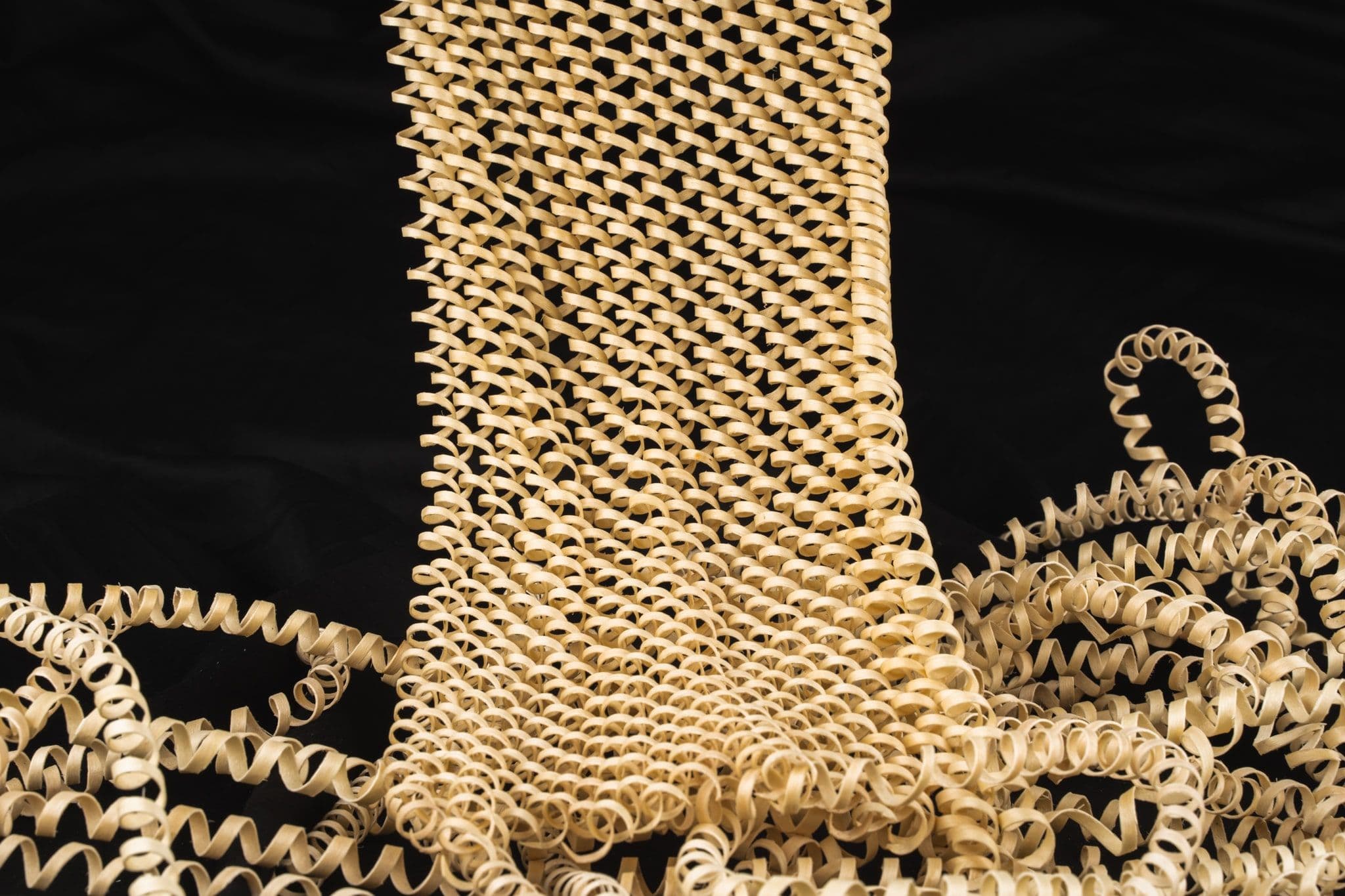

Regarding protection then our case studies show that our clients’ broken items have decreased to zero even during their most hectic shipping time. RAIKU products have a spring structure, which has a superior shock absorbance capability compared to alternatives. Springs are commonly used in other industries for the very same purpose. Think about the springs in car amortisation or mattresses for example.

Given the innovative nature of your wood spring technology, what specific research and development challenges did RAIKU face in designing a product that is both protective and environmentally beneficial?

It is a new industrial technology and production process, which is incredibly difficult to develop from ground zero because there has not been an existing similar technology on the market. Our team of engineers and development partners have had to spend thousands of work hours on prototyping, modelling and testing different methods to produce our packaging material in a fast, efficient, and stable way.

In addition, there are considerable bottlenecks in technology development phases once you move from lab scale to industrial prototyping and finally to scaling up the production. Every step adds another layer of complexity and more people are usually needed for each stage. In our case, we are still learning and hiring even more engineers to our cause to speed up the market penetration in time.

How does RAIKU ensure the raw wood materials used in its packaging solutions are sourced sustainably without contributing to deforestation or habitat destruction?

Our raw material, wood, is sourced from partners that have FSC, or PEFC certifications. These certifications demand that the suppliers sustainably harvest wood. In addition, we aim to fund reforestation initiatives as we increase our revenues.

Although we need a very small amount of wood compared to traditional wood industries, then we have set an internal goal that by our activities more forest is being grown than taken down.

Can you elaborate on the life cycle analysis (LCA) results that demonstrate RAIKU's packaging materials' lower footprint compared to conventional bubble wrap, paper, and other packaging materials?

In our LCA, we have analysed the transportation, raw material, energy and water use, and the end life of our products. Eco-friendly is a very relative concept, for example, many people consider paper and cartons as eco-friendly products but it is one the highest resource-intensive industries in the world. We have to look at the footprint analysis of both the production stage and the end life of our packaging materials.

For example, compared to paper and carton production RAIKU reduces wood use by over 90%, energy use by 98% and water use by 99.9%. In addition, chemical use will be reduced by 100% as we use none. Compared to paper/carton, RAIKU’s material offers a minimally 10 times smaller CO2 footprint.

The key to our case is how can we minimally process the biomaterials with maximum resource efficiency – if we can give 20 times more volume to the raw material (paper needs 2kg of wood for 1kg of paper), and if we need only 5 litres of water for 1 cubic metre instead of 50 000 litres of heated water, and we do not need 6 tons of chemical sludge for 1 ton of end product, then the math is simple. We can make a much lower carbon footprint product that is 100% natural, and it can be cheap because we need so much less costly inputs.

How has customer feedback influenced the development and refinement of RAIKU's packaging solutions?

Customers are part of our R&D team. It has been incredibly important, especially from the usability and design aspects. As a novel material and solution, in general, it is crucial to talk to as many customers as possible. We have changed our products quite a few times over the past years by talking to customers and subsequently engineering new products and options for the clients.

For example, we have changed the sizes of our packaging material according to the box sizes of the customers, and how we ship our products to clients, we have developed new products to meet their needs and planned several R&D projects for upcoming innovations. We constantly test new things with our open-minded clients.

What measures has RAIKU taken to scale production of its low-footprint packaging materials to meet growing market demand, especially among brands seeking sustainable packaging alternatives?

We have just moved to a larger production space and aim to expand our production units to new countries as soon as possible. Considering the amount of demand and interest in our material, we want to move fast and meet the demand. It is not an easy nor fast process to set up factories, but definitely an interesting challenge. There is also a possibility to license out our technology for markets where we cannot reach ourselves.