This article aims to explore the intricacies of alternative materials, and the challenges we must overcome to fully integrate them into our global supply chains.

Alternative materials: what are they?

At their core, alternative materials are engineered to provide the same or superior functionality as conventional materials while significantly minimizing environmental harm. This encompasses materials derived from sustainable sources, those requiring less energy-intensive production processes, and materials designed for enhanced recyclability or biodegradability.

Hemp is a good example of alternative materials. It is a fast-growing renewable resource that can be used to make various products, including clothing, paper, and building materials. Hemp is stronger than cotton and requires less water and pesticides to grow. Hempcrete, a building material made from hemp fibers and lime, has a lower carbon footprint than concrete and is also a good insulator.

Key concepts regarding alternative materials

Circular economy

A circular economy is an economic system aimed at eliminating waste and the continual use of resources. It is called a circular economy because all materials are part of a loop, with sustained value and no end-of-life phase pertinent to the creation and use of alternative materials.

As interesting as it sounds, implementing a circular economy can require significant initial investments in new technologies, infrastructure, and business models. Transitioning to a circular economy requires a fundamental shift in how industries and consumers operate. Resistance to change can come from various stakeholders, including companies, workers, and consumers, who may be comfortable with existing proven linear models.

Policies and regulations incentivizing circular practices, such as tax incentives for recycling, extended producer responsibility (EPR) laws, and anti-greenwashing labeling can be important steps to accelerate the transition.

Upcycling and recycling

Upcycling and recycling are processes that ensure that discarded materials don’t simply turn into waste.

Upcycling involves creatively transforming used materials into new items of higher value or quality. Conversely, recycling involves collecting used materials and breaking them down into new materials that can be reused.

Recycling undeniably plays a crucial role in mitigating waste and conserving resources. However, it's important to acknowledge that, in many cases, recycling can be seen as a form of downcycling. While glass is an exception, materials like paper, plastic, and metals suffer from a loss of quality with each recycling cycle, ultimately necessitating their disposal. This limitation underscores the need for a broader waste reduction strategy that encompasses not only recycling but also reducing consumption, reusing products, and designing materials for improved recyclability.

Biomimicry

In simple terms, biomimicry in material science is the practice of developing materials that mimic the structures, systems, and elements of nature for the purpose of solving complex human problems, often contributing to sustainability.

One interesting example is titanium dioxide’s potential replacement. It is widely used in road markings, personal care products, and food, poses environmental and health risks due to its mining and potential carcinogenicity. Researchers at Impossible Materials were inspired by the Cyphochilus beetle's reflective scales are creating a safer, more efficient white pigment from cellulose.

Bio-based materials

Bio-based materials are a category of alternative materials derived from renewable biological resources, such as plants, animals, or microorganisms.

These materials are produced through various processes, including extraction, fermentation, or synthesis, and are often used as substitutes for traditional, fossil fuel-based materials. Norway-based B’ZEOS develops bio-based packaging solutions to replace single-use plastic.

Green Chemistry

Green chemistry is a science that promotes the design of products and processes that minimize the use and generation of hazardous substances. For example, in industrial chemistry, the focus may primarily be on producing a window cleaner at the lowest cost and in large quantities to meet market demand. The formulation could include potentially harmful chemicals like ammonia or volatile organic compounds (VOCs), which are effective in cleaning but can have negative health and environmental impacts.

In contrast, green chemistry principles applied to the same product would lead to a different approach. In a green chemistry framework, the formulation of the cleaner would involve safer and more environmentally friendly ingredients. For example, it might use non-toxic surfactants and renewable solvents. The manufacturing process would also aim to minimize waste and energy use.

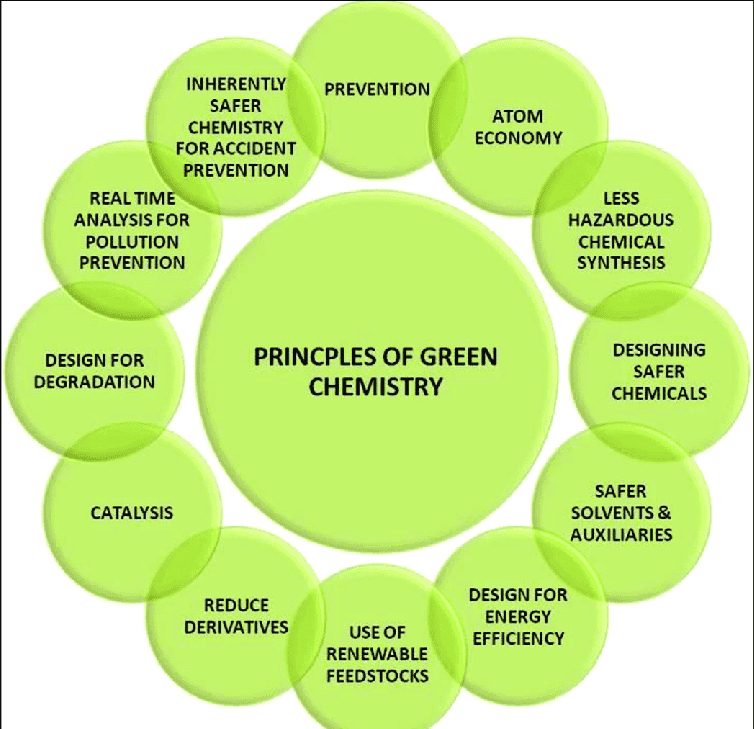

Green chemistry is anchored on 12 principles developed by John Warner and Paul Anastas, as seen below:

Biodegradability and compostability

Biodegradability is a property of materials that allows them to be decomposed by bacteria or other living organisms, crucial for reducing waste and adverse environmental impact.

On the other hand, compostability is the ability of a material to break down into a nutrient-rich soil amendment under specific conditions, such as those found in a commercial composting facility. Compostable materials must break down completely within a certain amount of time.

The purpose of biodegradability and compostability, in general, is to ensure that discarded products do not linger in the environment for years after use.

FAQs

1. What are the main challenges in developing and implementing alternative materials?

Technological limitations in production, higher costs, scalability issues, and slower acceptance within industries, particularly those with high safety and reliability requirements, are some of the main challenges in developing alternative materials.

One example of the technological limitations in producing alternative materials is the lack of efficient and cost-effective methods for producing graphene at scale. Graphene is a single layer of carbon atoms arranged in a hexagonal lattice, and it is the strongest and lightest material known to science. However, the current methods for producing graphene are inefficient and expensive, which limits its use in commercial applications.

2. What exactly are alternative materials?

Alternative materials are those developed or used in replacement of more traditional materials, typically characterized by their reduced environmental footprints, whether in terms of carbon emissions, energy use, or other ecological impacts.

Recycled aluminum cans use 95% less energy to produce than new aluminum cans from bauxite ore. This reduces greenhouse gas emissions and conserves resources.

3. Why are alternative materials important in the fight against climate change?

Alternative materials are vital in the fight against climate change because they often have lower carbon footprints and energy requirements, conserve resources, reduce waste, drive technological innovation, and promote sustainable consumption patterns. Their adoption, in ideal situation, contributes to reducing greenhouse gas emissions, mitigating environmental damage, and transitioning to a more climate-resilient and sustainable future.

4. Are alternative materials as durable and effective as traditional materials?

While it varies based on the specific material, many alternative materials are designed to meet or even exceed the durability and effectiveness of traditional materials. Plant-based bioplastics are effective and durable for packaging, yet they are more environmentally friendly, being derived from renewable sources and are (for the most part) designed to be biodegradable.

5. What industries are most affected by the shift towards alternative materials?

Virtually all industries are affected by this shift, but sectors like construction, automotive, packaging, and textiles are among the most significantly impacted due to their historical reliance on carbon-intensive materials. Plastic packaging accounts for 3.50kg of carbon emissions per 1kg, which is higher than aluminum and paper.

The textile and garment sector accounts for between 6 and 8 percent of total global carbon emissions, which amounts to 1.7 billion tonnes in carbon emissions per year.