What initially inspired the unique dual-purpose design of the Pocopiano ceramic plate, and how did you conceptualize the idea of combining solids and liquids in one design?

Initially, I wanted to design a plate wrapped around itself, similar to a blank page, with the sole purpose of telling a story. This is because a culinary and synesthetic path is increasingly required in restaurants.

Later, observing this particular helix shape, I understood its functional potential. Thus, a dish capable of separating liquid dishes from solid ones was born, creating new situations such as decomposed foods, tastings of oils, and culinary proposals dictated by the imagination of the chefs. Often, the ideation process of a product takes an autonomous direction, and we designers can only listen to and observe these small yet important suggestion

For the Pagina Collection, why did you specifically choose FSC-certified paper as the primary material, and how did you ensure that it remained durable and washable?

Essent'ial is an Italian company that produces a particular FSC-certified paper, washable and very resistant. They wanted to enhance this fantastic material by creating a collection of objects for school, the office, and everyday life, such as backpacks, pencil cases, and containers, where the theme of paper is predominant.

In fact, these objects feature the typical textures of notebook lines, such as rulers, squares, and graph paper. Furthermore, it is possible to write on these objects as we would on a normal piece of paper, much like we did at school.

Could you elaborate on the process of transforming potato peels into a sturdy material for Peel Saver? What was the biggest technical challenge in this project?

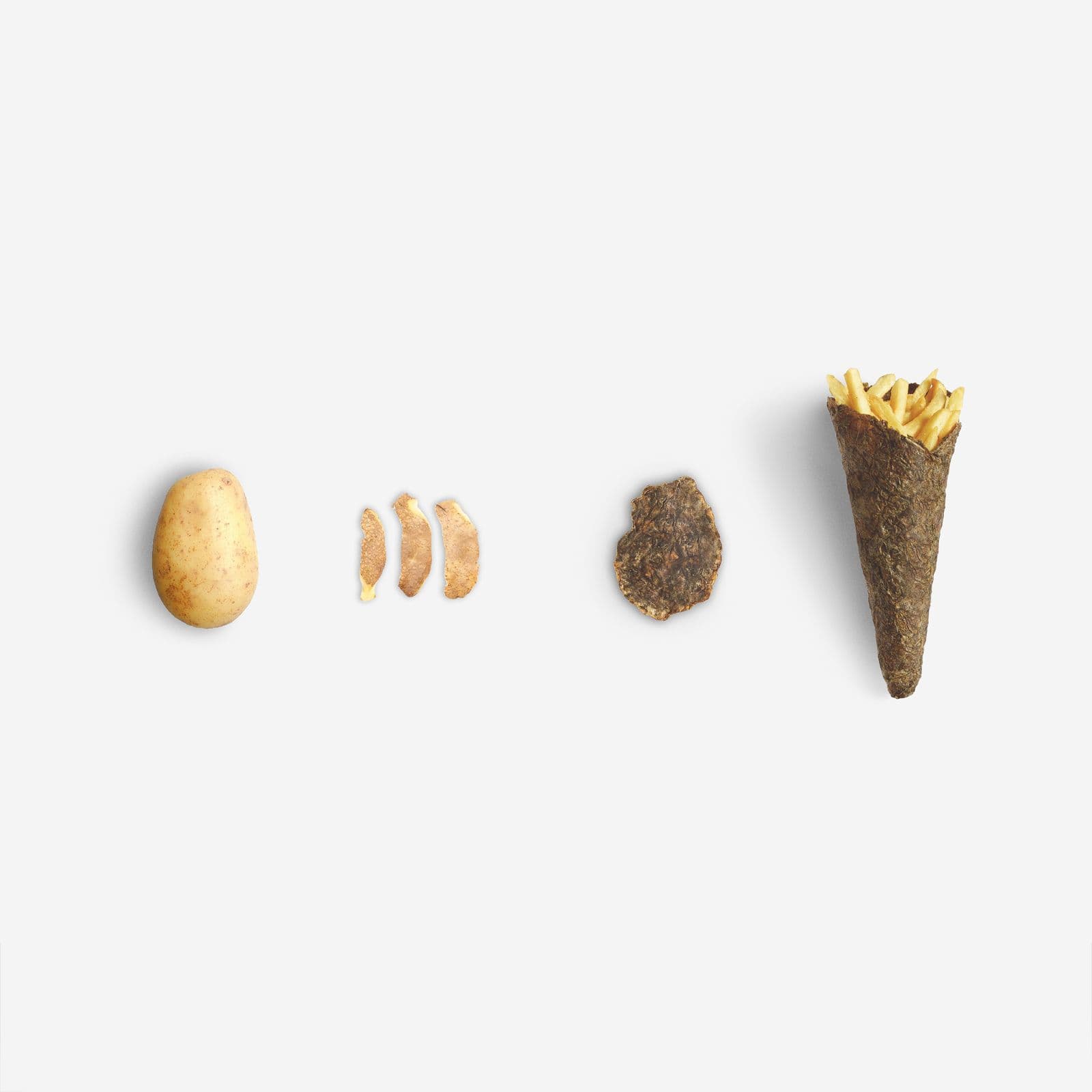

The Peel Saver project was born many years ago at NABA University in Milan. In a laboratory, we discovered that potato peels, composed of starches and fibres, have the ability to create a rigid material. To find the right formula, we carried out many tests and contacted various entities. The most important process is drying, with a method similar to that of paper.

The idea behind the project was that the peel would once again protect the potato in the form of packaging, just as it has always done in nature with the pulp.

For the Peel Saver, you've utilized potato peels, an organic waste product. What are the long-term viability and scalability challenges of using such materials in mass production?

To consider the use of potato peel, we conducted research on food waste. We were competing with the paper market, which over the years has reached very interesting levels of traceability and awareness.

The project was presented to various entities, but in terms of investments and mass production, it proved to be economically unsustainable. With this awareness, I then became interested in the world of FSC paper and the possibilities that this material could offer.

When working with clients like Orografie and Essent'ial, how do you align their brand identity and commercial goals with your creative vision and sustainability criteria?

With Orografie and Essent'ial, as well as with other companies, I have a relationship of complicity and mutual trust. I find it very important to have a transparent and stimulating dialogue.

With this perspective and vision, aspects such as identity, commercial needs, and my vision do not become obstacles but rather ingredients for a perfect recipe.

Reflecting on your body of work, which project would you critique the most critically today? What lessons have you learned from it?

I am very critical of my work. The Peel Saver project, as I mentioned, taught me that something that works as a system does not necessarily also work in the market. However, I believe that the message of the project contributed to seeing things from another point of view.

How do you see sustainable design evolving in the next five years, and what role do you hope to play in that evolution?

I have a precise idea of what I mean by "sustainable" for the next few years, and it involves materials that I define as eternal, such as metal, glass, ceramic, terracotta, etc. I believe that a well-designed object made from one of these materials can be passed down from father to son — almost a return to barter, where objects last and hold value. It would be an old but very new vision… a new renaissance.

Looking forward, how do you plan to integrate emerging technologies or materials into your future projects to further enhance sustainability and functionality?

I dream of crossing my path with that of another person or company; discovering a cool material or technology so we can work on it together. The best things come from collaboration.