Key Points

- Heavy-timber analogue: mycelium blocks deliver long service life when kept dry, yet are fully compostable at end-of-life.

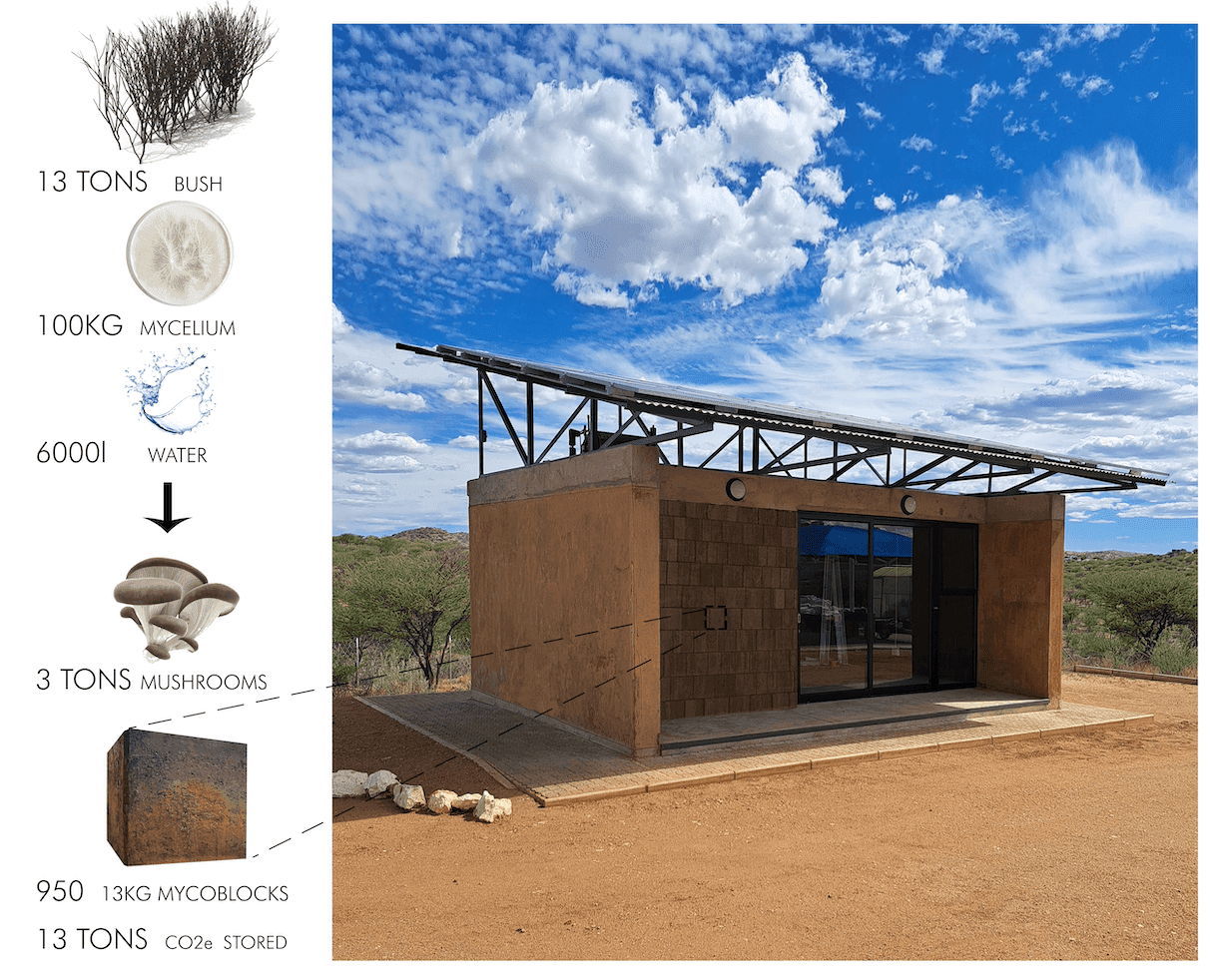

- Waste-to-resource feedstock: encroacher bush is milled for mushroom cultivation; post-harvest substrate becomes structural blocks: restoring ecosystems and supporting local livelihoods.

- Carbon math stacks up: blocks contain ~43% organic carbon, sequestering ~1.58 t CO₂ per tonne of material and yielding ~1 t CO₂ net storage after manufacturing,versus positive emissions for concrete and steel.

- Integrated and net-positive: vertically controlled chain (harvest → grow → build) plus an 11 kW solar array that produces surplus power.

- Built to scale, with caveats: a 1,000-block modular system is prefab-friendly; mainstreaming needs moisture-robust detailing, standardisation, and code acceptance.

Full interview with MycoHab

1. MycoHab uses fungal mycelium as a core building material in its self-supporting structure. How did you ensure the mycelium's durability and strength, particularly in comparison to conventional building materials like concrete and steel?

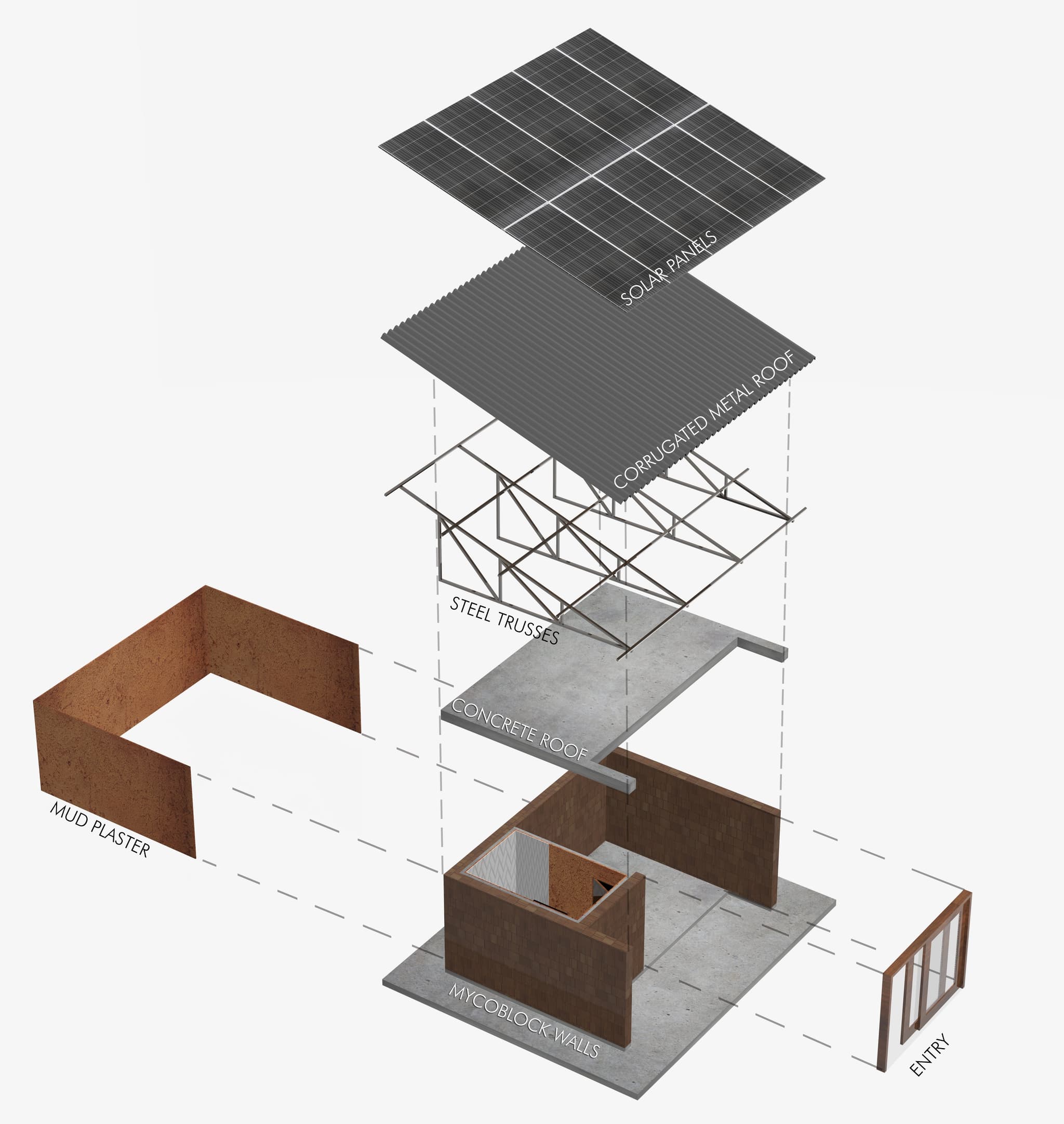

The materials we developed for MycoHab are most comparable to heavy timber. Like timber, they are extremely durable when protected from the elements but ultimately biodegradable at the end of their life cycle. Heavy timber has been used in construction since before recorded history, some timbers are still in place as shoring in the Bent Pyramid of Dahshur, over 4,000 years old. We believe all building materials should be either recyclable or compostable, and MycoHab exemplifies this principle. The structure is composed of myco-blocks that can last indefinitely if the exterior envelope is maintained. However, if the building is ever decommissioned, the metal roof can be recycled and the myco-blocks composted in place, enriching the soil.

2. The process of using blackthorn bush as a substrate for growing oyster mushrooms is a fascinating aspect of MycoHab. Can you explain the specific challenges you faced in integrating a natural, living material into architecture, and how you overcame them?

The use of encroacher bush as a substrate is a prime example of repurposing waste material as a primary input in manufacturing: supporting a circular economy and positioning mycotecture as a regenerative process. This bush has proliferated due to colonial land management practices that disrupted natural ecological cycles. Now, its overgrowth threatens biodiversity and depletes water resources. The bush is ground into a sawdust-like powder and used as the substrate for growing mushrooms. After harvesting the mushrooms, the cultivation byproduct, a composite of fungal mycelium and interwoven bush fibers, is used to create myco-blocks.

Challenges include susceptibility to mold or rot when exposed to excessive moisture. This can be mitigated through architectural detailing that protects the materials from water exposure. Additionally, certain fungal species and substrates have evolved natural resistance to mold and decay due to their ecological competition, offering further durability.

3. With the carbon sequestration capabilities of the mycelium blocks, how do you quantify the environmental benefits during the production process? Can you walk us through the lifecycle analysis, from raw material harvesting to the final use of the building blocks?

As the encroacher bush grows, it draws down carbon dioxide (CO₂) from the atmosphere and converts it into biomass. The captured carbon becomes part of long organic molecules: primarily lignin, cellulose, and hemicellulose in the plant’s cell walls.

Fungi digest these biopolymers and convert them into fungal biomass, mainly in the form of chitin. Some carbon is released through fungal respiration, some becomes fruiting bodies (mushrooms), and a significant portion remains in the composite plant-fungal material. When used as a building component, this carbon is stored, preventing its release into the atmosphere.

4. The blocks used in the MycoHab structure are said to have 43% organic carbon. Could you elaborate on the role of mycelium in carbon capture and how this contributes to the overall sustainability of the project?

MycoHab blocks contain 43% organic carbon, originally drawn from the atmosphere and transformed by fungi into a composite material. Using the standard conversion factor CO₂/C = 3.67, this equates to 1.58 tons of CO₂ sequestered per ton of material.

After factoring in emissions from manufacturing and transport, there is a net storage of 1 ton of CO₂ per ton of material. In contrast, concrete emits 1 ton and steel emits 2 tons of CO₂ per ton. MycoHab offers a climate-positive construction model.

5. The project employs a vertically integrated process, from bush harvesting to mycelium cultivation. How does this holistic approach influence the design and construction process, particularly when compared to more traditional, linear building methods?

Vertical integration has both organizational challenges and transformative benefits. Coordinating disciplines from bush extraction to construction requires effort, but enables each stage to be economically viable while also creating environmental and social impact.

6. MycoHab’s use of mycelium creates a material that combines the best properties of both Plantae and Fungi. Could you elaborate on the role of chitin in binding the fibers together and how this natural polymer contributes to the material’s strength and functionality?

Fungi digest plant substrates and grow mycelial networks, interweaving through ground plant material. As they secrete enzymes, lignocellulose is broken down, allowing fibers to lay flat when compressed and baked. During this process, chitin replaces weaker plant components, acting as a bioplastic binder that enhances strength and durability.

7. The project integrates renewable energy through an 11kW photovoltaic system. How does the use of this solar energy complement the regenerative architecture of MycoHab, and how does it align with your broader sustainability goals?

The initial MycoHab features an 11 kW photovoltaic system, generating more energy than it consumes. This fits with the project’s ethos: regenerative architecture that produces surplus energy, shares resources, and contributes positively to its environment.

8. With mycelium’s growing popularity in sustainable architecture, do you foresee this material becoming mainstream in construction, or are there specific barriers: whether technical, economic, or cultural, that need to be overcome?

Mycelium could become mainstream due to its carbon-storing and regenerative qualities. However, technical barriers like moisture and pest resistance, economic hurdles in vertical integration, and cultural skepticism must be addressed. Demonstration projects like MycoHab are crucial to shifting public and industry perception.

9. The use of 1000 mycelium blocks in the structure presents an innovative approach to modular construction. How do you foresee this technology scaling for larger building projects or urban applications in the future?

MycoHab’s modular design shows promise for scalable and decentralized production. Urban uses could include prefabricated panels with insulating and structural functions. Scaling up requires standardization, integration with traditional systems, and industry adoption to reduce embodied carbon.

10. Given the regenerative and carbon-neutral nature of MycoHab’s design, do you think this project can serve as a model for future sustainable architectural practices? How can other industries and sectors adopt similar methodologies to contribute to a more sustainable world?

Absolutely, MycoHab exemplifies regenerative design, transforming invasive biomass into carbon-storing architecture that produces surplus energy. Other sectors can emulate this by adopting waste-to-resource strategies, focusing on carbon sequestration, and using low-energy, modular fabrication methods. Materials must be seen as active ecological participants, not inert inputs.