Key Points

- Eco-design first: assess inputs/outputs across the lifecycle, compare like-for-like (incl. Scope 3), and design for end-of-life from the start.

- Prints, colour and finishes are the impact hot-spots; shift to safer chemistry, water-light dyeing, and accept natural variation over rigid uniformity.

- Viable alternatives exist: biosynthetics and bio-finishes, PFAS-free coatings, microbial/plant dyes, and high-performance natural fibre tech (e.g., Optim® wool).

- Collaboration is the unlock: brands, mills, chemists and startups must co-develop, trace feedstocks, and digitise supply chains for transparency.

- Use clear criteria (durability, recyclability, biodegradability, performance) to match context and reduce total impact.

Full interview with Elsa May

Can you describe the process and criteria you utilise to evaluate and select sustainable materials for fashion trends, focusing on innovation and environmental impact?

That process is a very complex one, depending on the multiple criteria that you have to take into account simultaneously, and it mainly depends on where your priorities are set. It's about balancing between durability, recyclability, or, even more trickly, biodegradability.

But very likely, the keys are found in the core of Eco-Design, meaning taking into account every step of the material production, the knowledge about the inputs needed, and also the outputs at each stage (in terms of energy, water, chemicals, GHG emissions, etc ..) and who is impacted by it (humans, environment, biodiversity…). This involves considering the end-of-life of the product, right from the start at the design stage.

Questions to be asked include:

- Is the process of this material a closed loop? This can mean producing as little waste as possible, re-using every spare/leftover, filtering, reusing, closing the loop - but also using the only needed amount of primer material, of energy, water, chemicals, etc. Often, it’s common sense that I think would be good to get back to. A kind of simplicity in thinking. As a rule of thumb: the least transformed the better - the closer the better - lower transport, lower energy consumption, lower impact.

- What is the environmental and social footprint of the material? This means to get into research and get the data through tools - and compare it to conventional materials produced in the same region and/or way. It's worth noting that you have to compare what is comparable, and going to scope 3 here seems essential to me. Is there a risk of exploitation, or is it, on the other hand, a mutually enriching collaboration between producers, growers, and the designers?

- What are the features that you really want the material to have, that are non-negotiable? For example, certain products need special performances, so they probably will not be made in natural fibers to meet these high resistance standards but will meet durability expectancies, so they last a longer time, and therefore, in the end, produce less waste.

Or maybe, they actually do not need these performances, or not as high (how much waterproofing is really necessary in our majority urban lifestyles?). There are amazing technological innovations with natural fibers, meeting high levels of performance, like the Optim® technology co-developed by Nanshan and The Woolmark Company, that pre-stretches Merino wool fibers which are then spun into yarn before being woven to create wind and water-resistant fabric made from 100% Merino wool.

They designed and developed the Luna Rossa Prada Pirelli team uniform for the 37th America’s Cup. The uniforms further cement Merino wool’s rightful place as a new breed of natural-performance sailing wear. They also developed a high-end Vilebrequin swimsuit in this 100% merino wool Optim® fabric.

In the report Understanding ‘Biomaterial innovations from Biofabricate and Fashion For Good, there is this final note, which resumes it well: "While fashion brands may desire a black and white answer to the question “which is the most sustainable material or process?” unfortunately it’s not possible to hold up any one process as “better” than another when there are so many potential variables in each system. Many materials can be described as biomaterials, but the “bio” prefix masks underlying differences in technologies, complexity, and potential impacts. All ‘biomaterials’ are not the same."

The good news is, nowadays there are really beautiful, both in a visual and tactile way - and performant, scalable sustainable developments. This is essential to make sustainability and circularity desirable, and make it a reality in the market.

So when there are materials that feature innovative approaches and a measured lower impact - may they be biobased, upcycled, recycled in a closed loop. For example, these amazing knits from Pyratex, that offer an incredibly large range of developments with pleasing feels, handles and visuals, it all makes a clear and bright vision for a cleaner future of fashion.

What challenges do you face in synthesising fabric trends, particularly with regards to print & decoration specialisations?

We know that the impact of the "fancy sector", the decoration, prints, and fancy fabrics - including fake fur or fake leather, is huge.

The major part of its attractiveness comes from colour - that essential element to create desire, that immediately "speaks to our soul" (Vassily Kandinsky), it is a signature, an unmissable tool for recognisability; it is this indispensable touch for catchy prints, motifs, and patterns.

Colour - including black, whose darkness is directly related to petroleum - and finishes, prints, shine, sequins, and glitter are the most powerful visual expressions of fashion, and conjunctly, their impact on our living planet is also one of the most harmful. Dyeing is said to be responsible for 20% of water pollution worldwide.

Even natural dyes have an impact on potentially toxic mordants. The questionable (maybe obsolete?) standard of replicability and uniformity of colour is leading to its reliability on fossil-based, non-renewable sources.

Glitters, sequins, etc are all based on plastic. Non-degradable and responsible for skin irritation, endocrine disruption, health problems, destruction of aquatic fauna, and so on. Examples of these chemicals can be found on ZDHC’s Manufacturing Restricted Substances List.

Unfortunately, this very important sector Prints & Decoration has also been the least up-to-date and proactive in the R&D up to now. That’s why it’s that sector where I find it most exciting to dive into, because there is so much to do!

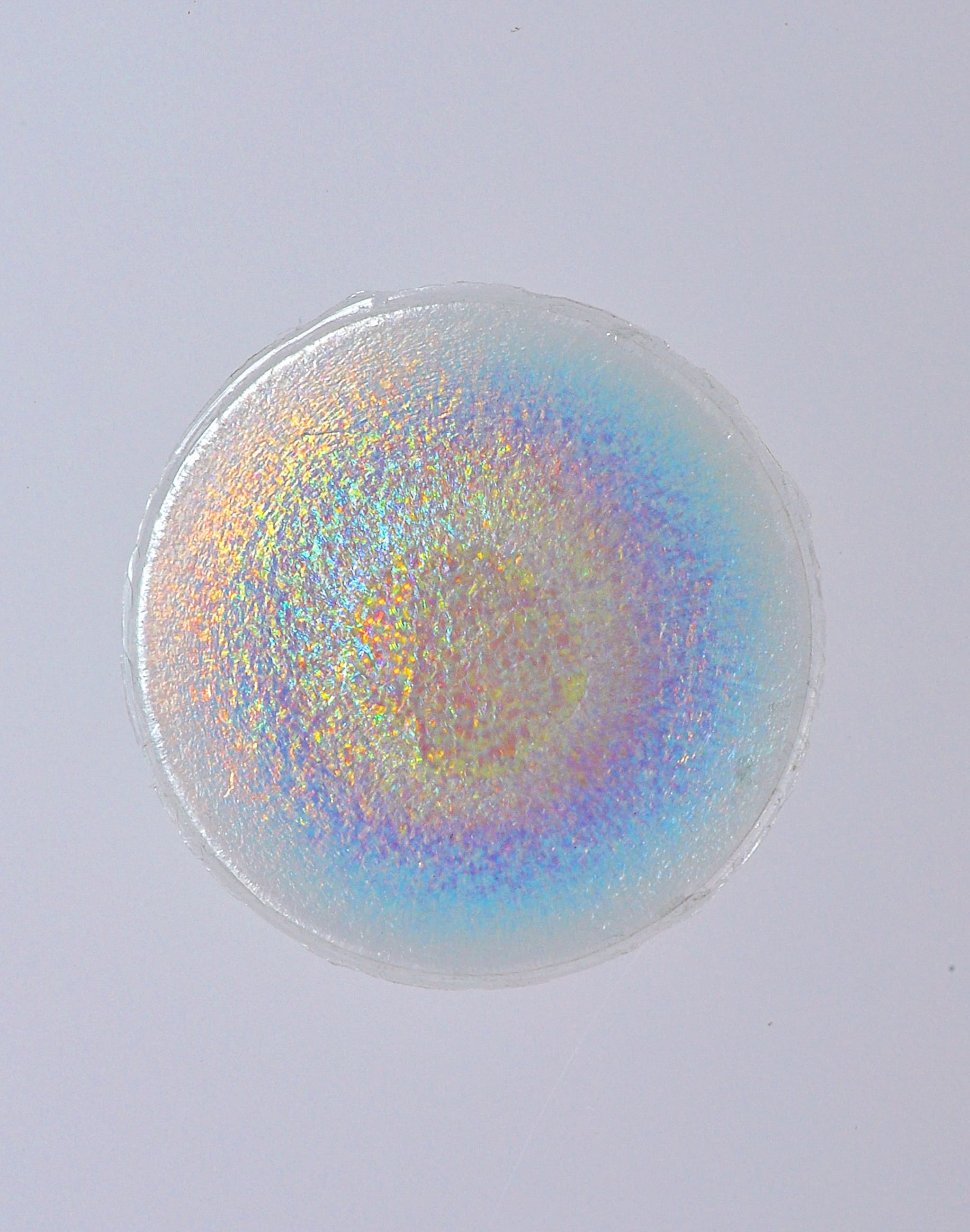

Yet disruptive innovations in the chemistry field, e.g the Biosequin from Radiant Matter, or biobased Fake-Furs like Biofluff, as well as game-changing processes in machinery that prioritise lower energy water, and chemical requirements compared to conventional methods (a.o waterless dyeing technologies, via supercritical CO2 like Deven Supercriticals or Ultrasonic dyeing like Indidye) are entering the market. They offer really virtuous alternatives to fabrics, leathers, furs and dyes with non-hazardous chemicals formulated from plants (like Malai's coconut water-based Leather), algae (Keel Labs e.g), microbial action (Colorifix that are Oekotex certified e.g), recovered resources like agrifood waste (like Sages London for dyes), etc…Not only are they way less impactful on the environment and based on renewable resources, they are also making degradability a reality, and broadening the options for smart sourcing.

Synthesising all these into trends is not easy, it seems essential to me to go into details of each and dig deep, and explain again and again: decisions have to be made, there is not One perfect solution applicable to the whole world.

I also would like to stress a solution that will rely more on changing the mentality, shifting the paradigms, in a broader sense, about the living state, the natural occurrence of evolution in material, and especially regarding colour. Instead of demanding exact replicability, let’s celebrate the beauty of uniqueness! And that changing, living colours, mutating, and evolving with time is beautiful. This has been accepted in leather as a luxury tradition.

Could you explain your methodology with the series "Smart Solutions", in terms of research and editorial approach to sustainable innovations and solutions?

The foundation of it all is a constant watch that I keep on the latest innovations going on in the field - be it textile or material innovations via articles, webinars, as well as confront a little bit more dry - for example, legislative matters, and dive deep into the complexities of material innovations that cross biochemistry, physics and engineering.

Also of course a lot of stimulating and insightful exchanges with experts from the industry - but also visiting most prospective shows like Future Fabrics where you discover new emerging innovators.

Regarding multiple, profound and complex challenges the fashion industry is facing, as well as the implementation of the European, French, American and global legislations, and to protect their stakeholders and workers at each stage of production, the need for information and for legible solutions is blatant.

With this new article series called "Smart Solutions" in VIEW-PUBLICATIONS, the aim is to provide inspirational and clear content to help our creative peers (you, readers, industry professionals, future and mature designers and creatives) to understand, envision and grasp the big picture - but most importantly, to provide existing solutions.

I also always try to encourage (not only myself) but also important personal research, for the essential first steps being the understanding of the fundamentals of sustainability (like taking part in Climat Fresks, or seeing Kate Raworth’s exceptional talk on the Donut theory)

These pages do not have any presumption more than simply sharing an as precise as possible discovery of exciting developments and stimulating ideas that go actively towards a transformation of the actual fashion system.

In collaboration with other agencies, how do you approach solution consultancy for sectors like outdoor, cycling sports, and activewear to ensure both sustainability and performance?

The outdoor and sports sector, along (and hand-in-hand, crossing over) the knitwear sector, has always been the most proactive in R&D.

The emergence of biosynthetic, wholly or partly derived from natural, renewable sources such as corn, (Virent) sugar beet, sugarcane (Spiber, and their ‘Brewed Protein Fibre, which offers a wide range of products made from fermentation) wheat, or castor oil (Evo by Fulgar and Rilsan by Arkema) are replacing conventional synthetic fibers, with the same performance as their fossil-based counterparts. The challenge here is the responsible sourcing of managing of their feedstocks, especially because they attract a lot of attention now.

Regarding coatings and finishings, there are more and more PFAS-free and totally degradable coatings in R&D and on the market, really taking on green chemistry and biotechnology, like

Earth Protex eco-friendly protective coatings based on nanotechnology, Ecorepel Bio by Schoeller, or the MiDori bioWick from Beyond Surface Technologies based on microalgae oil.

What emerging trends or technologies in sustainable textile production are you most excited about exploring or implementing?

The more I dive into the complexities of these questions, the more I feel the importance of highlighting, supporting, and valorising technological knowledge with the development of new materials.

Equally, the industry needs to take the step into digitisation further to bring traceability and transparency into the whole supply chain. AI should be a help, a tool, one has to understand how to use and take profit from.

In the best practices, regenerative is so important. It is another approach, it is on top of everything that needs to be done. And at the same time, it is the foundation, the original way to do it, the most natural and respectful way of producing. It involves also that collaborative work, that supporting the industry down to the hands in the field and the dirt, far away from the glitter and the strass.

Yet still the fancy sector of decoration remains one that I feel the most needed to improve, that’s where research needs to be done and that work will certainly be key because it is one of those that makes fashion strive.