The issue of single-use plastic pollution can be considered a growing global crisis, posing serious environmental and health challenges.

These disposable items, include grocery bags, drink bottles, straws, and food packaging, often used just once before being discarded.

These items are often made from low-cost, petroleum-based polymers like polyethylene, polypropylene, and polyvinyl chloride which, due to their synthetic nature, do not biodegrade and persist in the environment for hundreds to thousands of years.

Imagine creating an item that can last for hundreds to thousands of years, but use it for a couple of minutes then discard it.

This doesn’t make much sense if we really think about it.

)](/_next/image?url=https%3A%2F%2Fstorage.googleapis.com%2Ftocco-cms%2Fthe_times_of_india_plastics_3_2278996237%2Fthe_times_of_india_plastics_3_2278996237.jpeg&w=2048&q=75)

According to the research of OCED, in 2019, a mere 9% of plastic waste was recycled on a global scale. The remaining plastic waste was distributed as follows: 50% ended up in landfill sites, 19% was incinerated, and 22% was either disposed of in nature or burned in the open air.

Alarmingly, approximately 22 million plastic waste items are discarded in nature annually. These items cause great harm to wildlife and enter the human food chain. Humans digest 5 grams of plastic each week, equivalent to a credit card.

Just stop single-use plastics: isn’t it that simple?

The situation with single-use plastics is indeed dire. Yet, stopping single-use plastics altogether is not that simple, especially when it is used in various applications, in which there are no plausible and cost-effective alternatives.

For example, the graph below shows examples of different uses of plastics in healthcare. It is not easy to replace plastics as materials for medical consumables such as face masks, blood bags, and gloves at the moment. During the Covid breakout, 3.4 billion single-use face masks and face shields were discarded daily.

)](/_next/image?url=https%3A%2F%2Fstorage.googleapis.com%2Ftocco-cms%2F1_3b9ab059cb%2F1_3b9ab059cb.png&w=2048&q=75)

That being said, with other applications such as packaging, household & leisure, agriculture, and automotive, it is completely possible to part ways with plastics.

The graph below shows the polymer type by sector in Europe. The packaging sector, which extensively utilizes PET plastic, accounts for the biggest portion of plastic demand in Europe (39.9%). This usage of single-use plastics is indeed being challenged - with increasingly stringent regulations on single-use plastics in packaging in Europe, China or South East Asia, etc.

)](/_next/image?url=https%3A%2F%2Fstorage.googleapis.com%2Ftocco-cms%2FPolymer_type_by_sector_demand_in_Europe_7febd2ada6%2FPolymer_type_by_sector_demand_in_Europe_7febd2ada6.jpg&w=2048&q=75)

Generally speaking, there are two ways to replace single-use plastics in packaging: one is through reusable and refillable systems, and another is through alternative materials. While the former solution is interesting, though not without challenges (infrastructure requirements, behavior change, collaboration needs, economic viability, etc.).

In this article, we will focus on the latter solution, which is interesting due to its potential to eliminate the need for behavior change and complex infrastructure requirements.

Alternative materials to plastics: bioplastics or bio-based plastics?

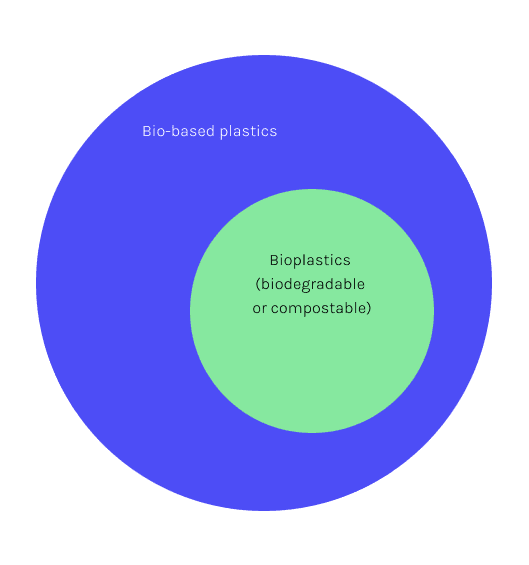

The terms "bioplastics" and "bio-based plastics" are commonly used interchangeably by the general public, but their meanings and definitions can vary, leading to ongoing industry debate.

Some people use "bioplastics" specifically for biodegradable or compostable plastics, while others use it more broadly for all bio-based plastics.

At tocco, we define it as follows:

This means:

Bio-based plastics encompass both biodegradable and non-biodegradable plastics, utilizing renewable resources such as plants or biomass.

On the other hand, bioplastics are plastic materials that originate from renewable sources like plants, vegetable oils, or starches, aiming to minimize environmental impact by being biodegradable or compostable.

A zoom into biodegradable bioplastics: PLA, PHA, and edible plastics

This category of bioplastics is indeed interesting, as these materials come from renewable sources and naturally break down over time.

However, it is important to note that the rate and extent of biodegradation can vary depending on factors such as temperature, moisture, and the presence of microbial activity. Also, proper disposal methods, such as industrial composting or specific waste management systems, should be followed to ensure the effective biodegradation of PHA materials.

Some examples of biodegradable bioplastics are polylactic acid (PLA), polyhydroxyalkanoates (PHA), and edible plastics (e.g. Polysaccharides, proteins, starch-based and lipids).

- Polylactic acid (PLA): PLA is a bioplastic derived from renewable sources such as corn starch or sugarcane. It has the ability to break down naturally through microbial processes under specific conditions, such as in industrial composting facilities

- Polyhydroxyalkanoates (PHA): PHA is a type of biopolymer that is produced by certain microorganisms. PHA has gained attention as a promising alternative to conventional plastics due to its biodegradability and renewable sourcing potential.

- Edible plastics such as polysaccharides (i.e. complex carbohydrates or sugar chains), protein-based, starch-based, and lipid-based plastics.

Conclusion

The transition towards alternative materials for single-use plastics is indeed not easy. Challenges to the widespread adoption of these materials are cost, scalability, and infrastructure compatibility.

Transitioning entire industries away from single-use plastics will indeed require significant investment and changes in design and manufacturing processes. The result of the transition, however, can be very rewarding.